12RES, 8.5RES specifications

The Kohler 8.5RES and 12RES generators are known for their robust reliability and efficiency, making them ideal solutions for both residential and light commercial applications. These generators are equipped with advanced technologies that ensure seamless power delivery during outages, giving users peace of mind.The Kohler 8.5RES, with its 8.5 kW output, is perfect for homeowners who require backup power for essential appliances and systems. It efficiently powers refrigerators, lights, and heating or cooling systems, providing convenience when the grid is down. The 12RES, delivering 12 kW, caters to larger homes or small businesses, accommodating additional loads such as sump pumps and electric dryers.

One of the standout features of these generators is the Kohler Command PRO engine, designed for maximum performance and longevity. This engine operates with low noise levels, ensuring that any power interruption goes unnoticed. Both models come with an innovative digital control panel that simplifies operation and monitoring, allowing users to access critical information at a glance.

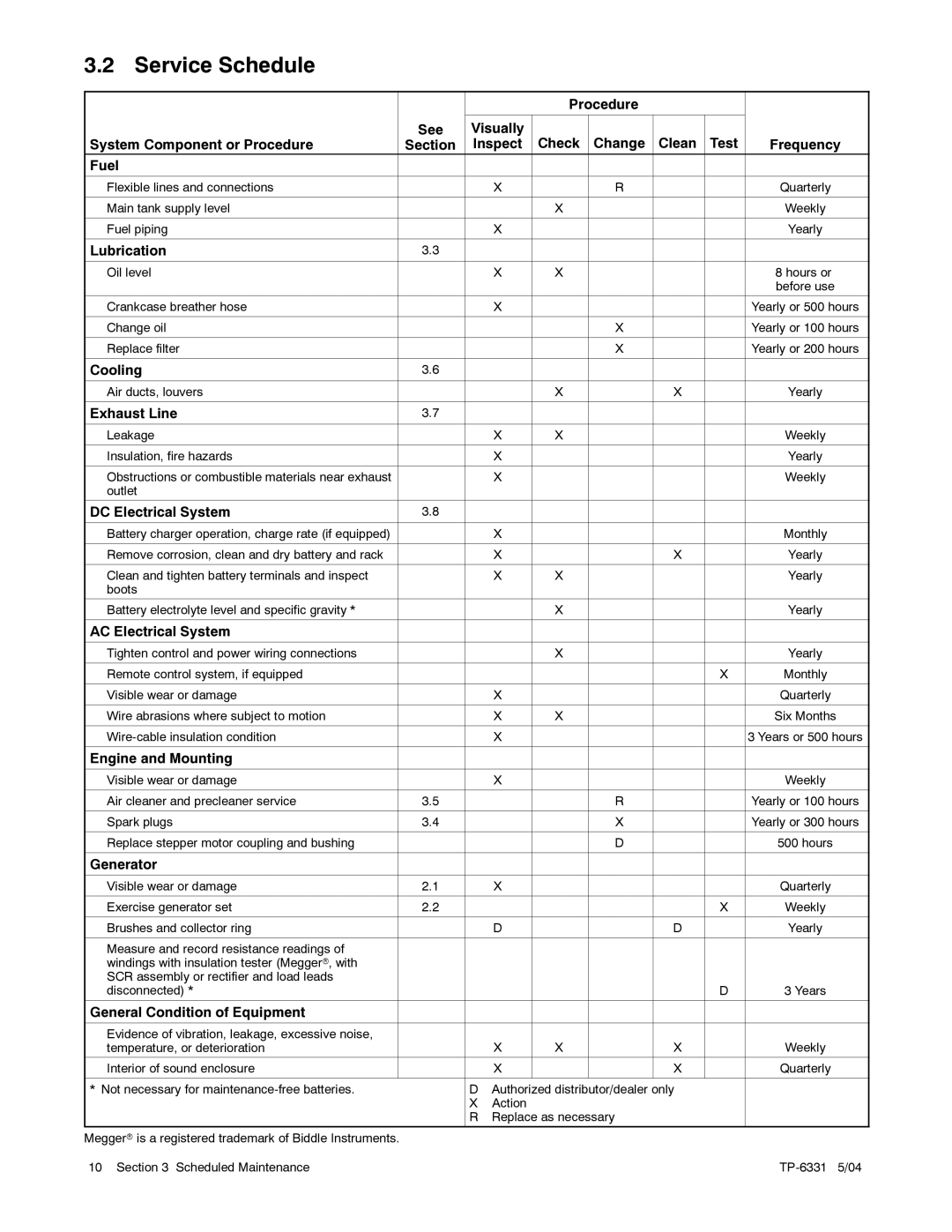

The Kohler 8.5RES and 12RES are equipped with the patented Automatic Voltage Regulation (AVR) technology. This feature maintains a steady voltage output to protect sensitive electronics from damage caused by power surges. The modular design of these units facilitates easy maintenance, with service intervals and replacement parts readily available.

For eco-conscious consumers, the Kohler generators meet EPA emission regulations, ensuring a cleaner energy solution. The units also offer a comprehensive sound-attenuated enclosure, resulting in quieter operation, making them suitable for use in suburban environments.

Installation is straightforward, with various connection options for natural gas and propane fueling. Both models come with a fully automatic transfer switch, providing seamless transition from grid to generator power. This ensures that critical systems are always operational during outages.

In summary, the Kohler 8.5RES and 12RES generators stand out for their reliability, advanced technology, and user-friendly features. Their powerful engines, efficient performance, and low emissions make them an excellent choice for anyone looking to invest in a dependable backup power solution. Whether for home use or light commercial needs, these generators provide the essential peace of mind that comes with knowing you have power when you need it most.