4.Remover the existing

5.Remove the pressure tap valve cores from the 4HP18LT units service valves. Connect an

6.Set the recovery machine for liquid recovery and start the recovery machine. Open the gauge set valves to allow the recovery machine to pull a vacuum on the existing system line set and indoor coil.

7.Invert the cylinder of clean

8.After all of the liquid refrigerant has been recovered, switch the recovery machine to vapor recovery so that all of the R-

22vapor is recovered. Allow the recovery machine to pull a vacuum on the sytem.

NOTE: A single system flush should remove all of the mineral oil from the existing refrigerant lines and indoor coil. A second flushing may be done (using clean refrigerant) if insufficient amounts of mineral oil were removed during the first flush.

After each system flush, allow the recovery machine to pull a vacuum on the system at the end of the procedure.

9.Close the valve on the inverted

10.Use nitrogen to break the vacuum on the refrigerant lines and indoor coil before removing the recovery machine, gauges, and

11.Install the fixed orifice (or thermal expansion valve approved for use with R410A refrigerant) in the liquid line at the indoor coil.

Refrigerant Metering Device

4HP18LT units are designed for use with TXV systems. Refer to the appropriate following section for information on installing the chosen refrigerant metering device.

An R410A system will not operate properly with an

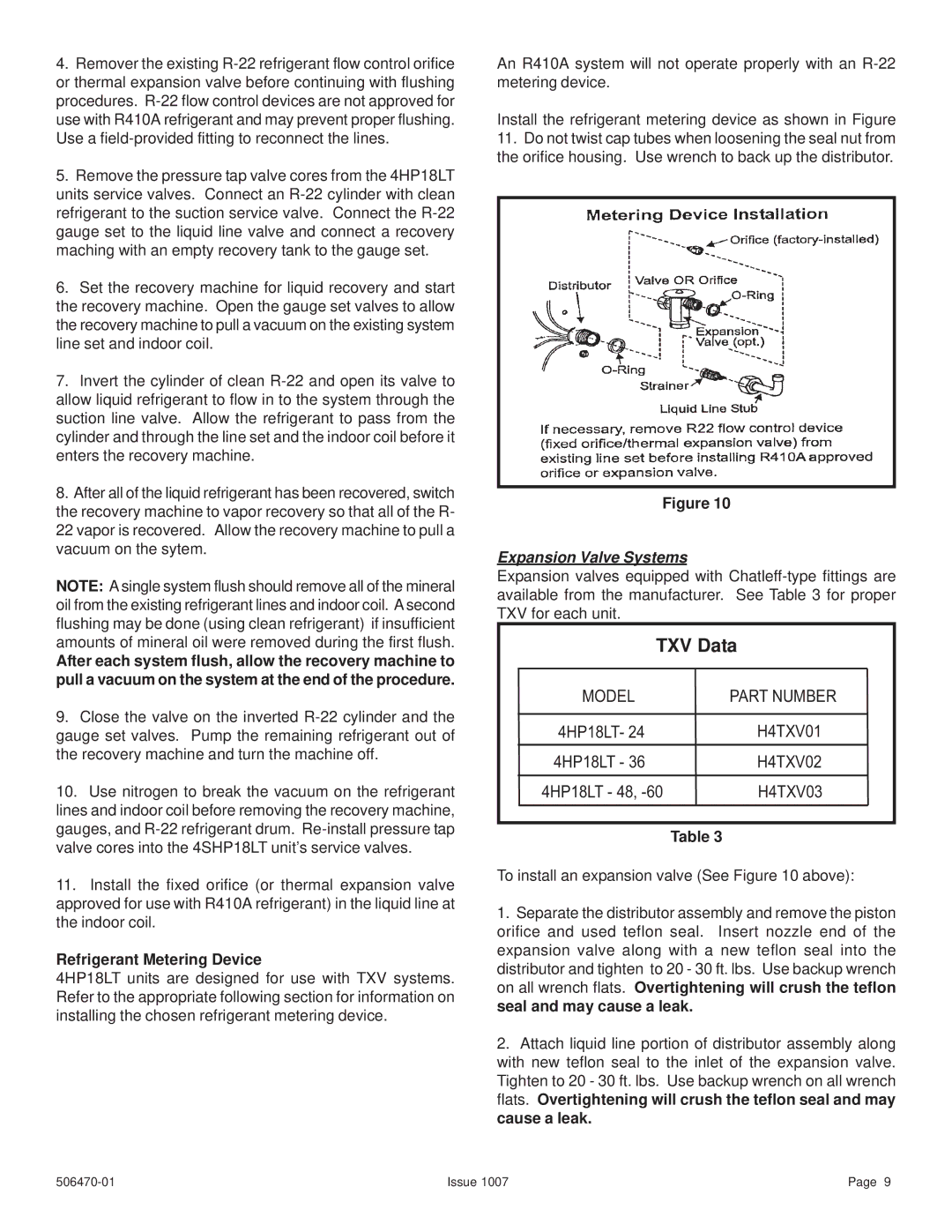

Install the refrigerant metering device as shown in Figure

11.Do not twist cap tubes when loosening the seal nut from the orifice housing. Use wrench to back up the distributor.

Figure 10

Expansion Valve Systems

Expansion valves equipped with

TXV Data

MODEL | PART NUMBER |

4HP18LT- 24 H4TXV01

4HP18LT - 36 H4TXV02

4HP18LT - 48,

Table 3

To install an expansion valve (See Figure 10 above):

1.Separate the distributor assembly and remove the piston orifice and used teflon seal. Insert nozzle end of the expansion valve along with a new teflon seal into the distributor and tighten to 20 - 30 ft. lbs. Use backup wrench on all wrench flats. Overtightening will crush the teflon seal and may cause a leak.

2.Attach liquid line portion of distributor assembly along with new teflon seal to the inlet of the expansion valve. Tighten to 20 - 30 ft. lbs. Use backup wrench on all wrench flats. Overtightening will crush the teflon seal and may cause a leak.

Issue 1007 | Page 9 |