left side of the saw’s frame and loosening the set screw on the brass arbor. Move the wheel to the correct position, check with the ruler or scale, and secure the set screw.

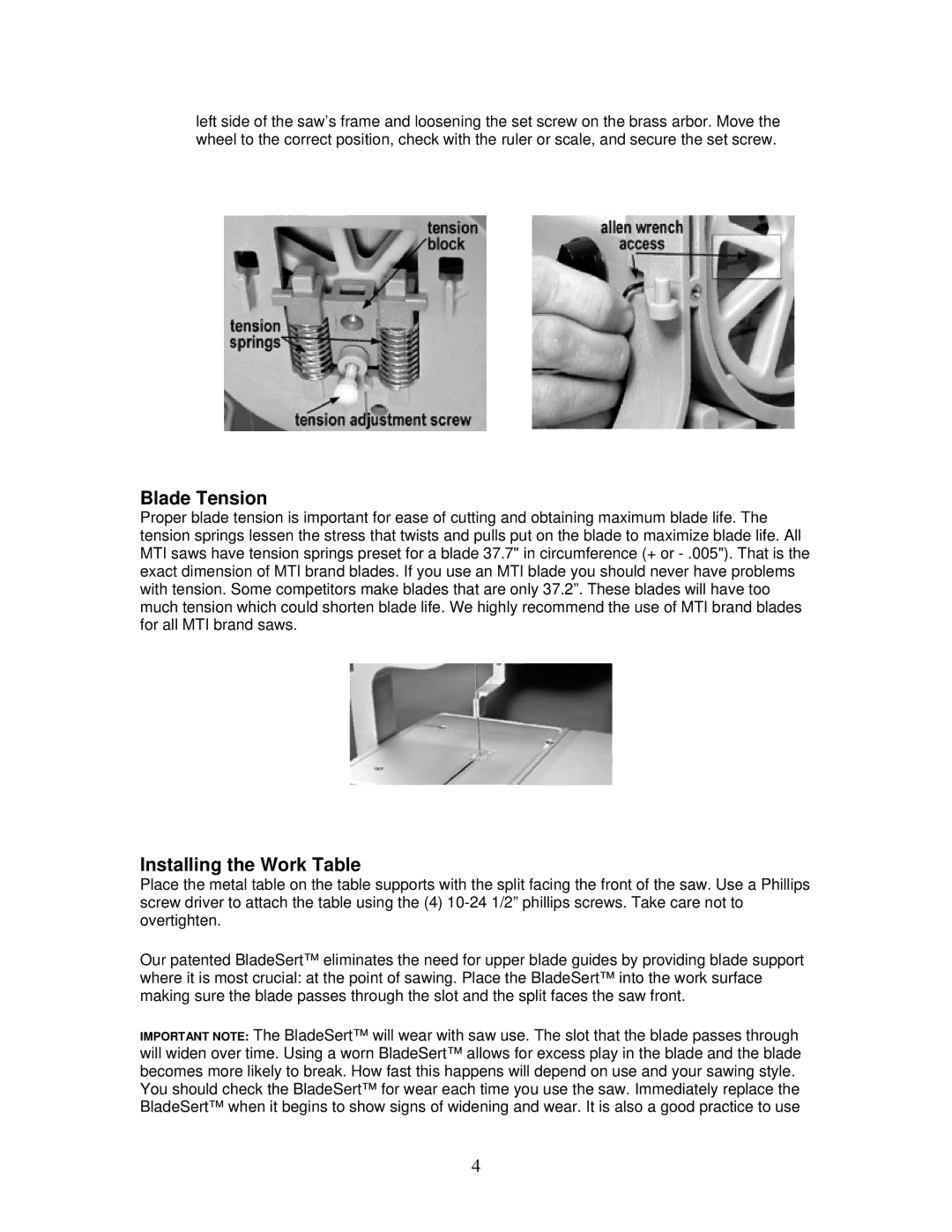

Blade Tension

Proper blade tension is important for ease of cutting and obtaining maximum blade life. The tension springs lessen the stress that twists and pulls put on the blade to maximize blade life. All MTI saws have tension springs preset for a blade 37.7" in circumference (+ or

Installing the Work Table

Place the metal table on the table supports with the split facing the front of the saw. Use a Phillips screw driver to attach the table using the (4)

Our patented BladeSert™ eliminates the need for upper blade guides by providing blade support where it is most crucial: at the point of sawing. Place the BladeSert™ into the work surface making sure the blade passes through the slot and the split faces the saw front.

IMPORTANT NOTE: The BladeSert™ will wear with saw use. The slot that the blade passes through will widen over time. Using a worn BladeSert™ allows for excess play in the blade and the blade becomes more likely to break. How fast this happens will depend on use and your sawing style. You should check the BladeSert™ for wear each time you use the saw. Immediately replace the BladeSert™ when it begins to show signs of widening and wear. It is also a good practice to use

4