Installation and Commissioning

5.3Water Connection

The heat exchanger can be pulled out for servicing

Water pipes should be connected so that the heat exchanger can be pulled out when the connection is undone. If the heat exchanger is connected to the water circuit using threaded fittings, the pipe fitting must be supported on tightening.

Before commissioning the server cabinet, the pipe connections should be checked for leaks according to local codes.

5.3.1Preparing Heat Exchanger for Initial Commissioning

Check the mechanical installation and the supply pipe connection.

Figure 6 Heat exchanger access

Remove this air duct

for bleeding, draining the heat exchanger and checking the valve

1.Carefully bleed heat exchanger when filling the system.

2.Open the air bleed valve until the water coming out has no bubbles.

3.Close this valve after bleeding.

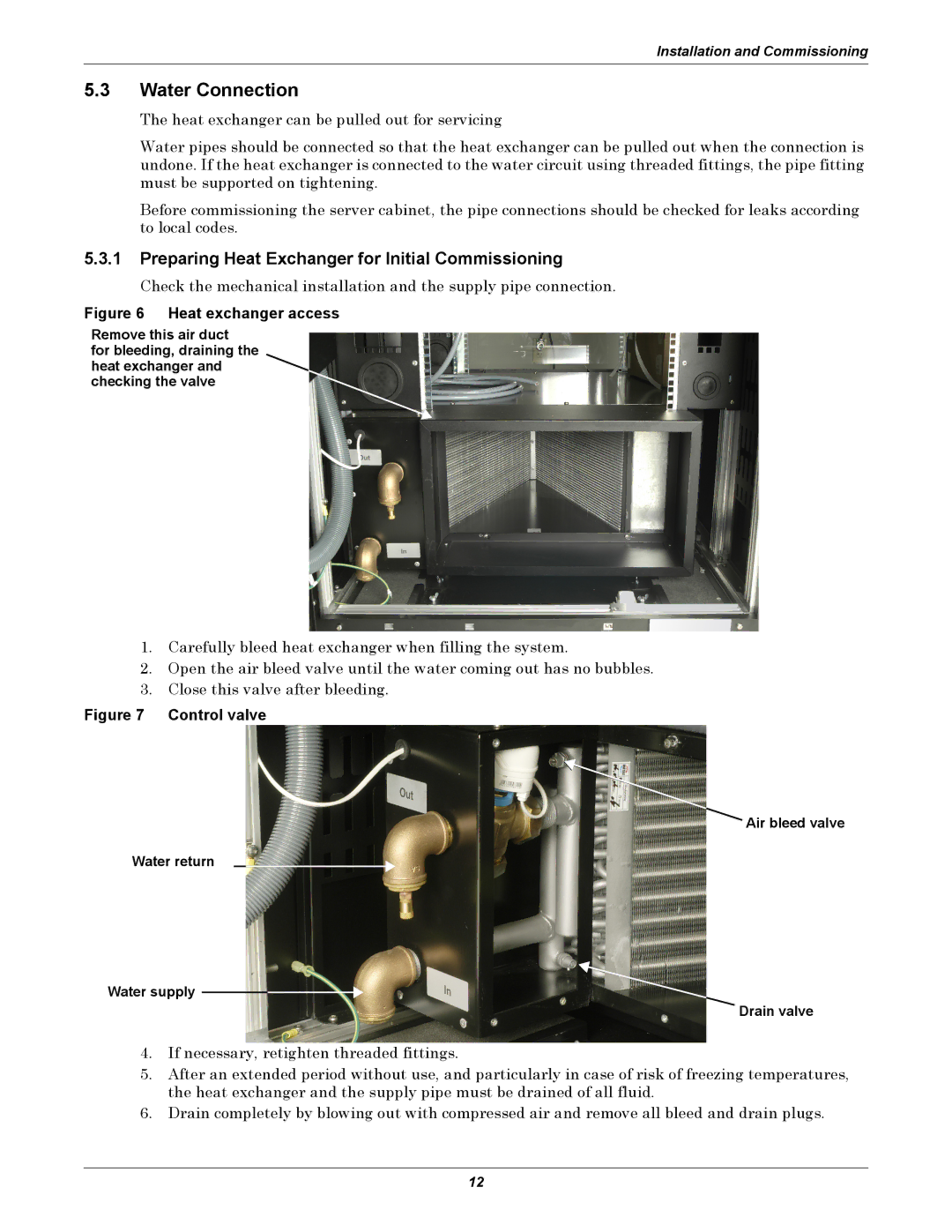

Figure 7 Control valve

Air bleed valve

Water return

Water supply

Drain valve

4.If necessary, retighten threaded fittings.

5.After an extended period without use, and particularly in case of risk of freezing temperatures, the heat exchanger and the supply pipe must be drained of all fluid.

6.Drain completely by blowing out with compressed air and remove all bleed and drain plugs.

12