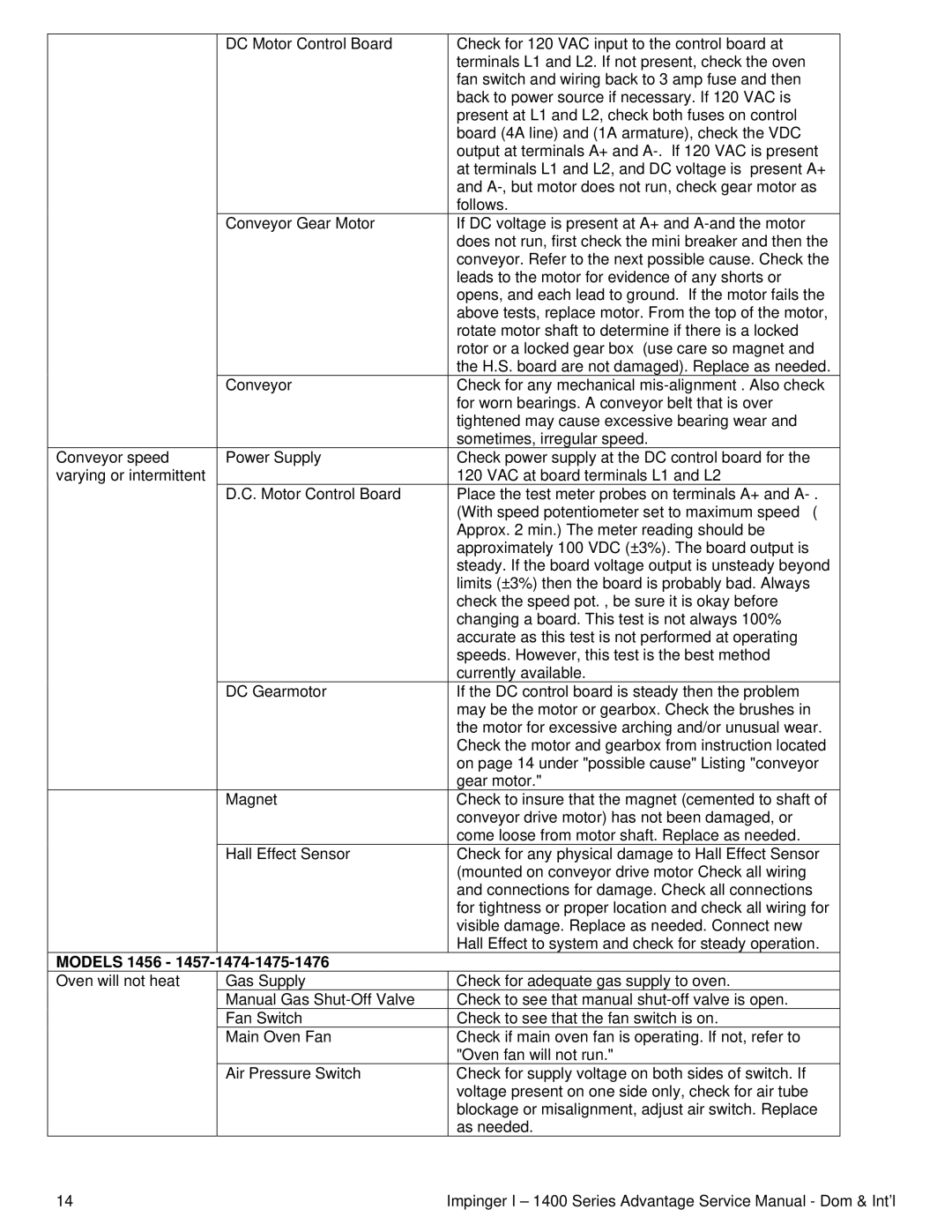

| DC Motor Control Board | Check for 120 VAC input to the control board at |

|

| terminals L1 and L2. If not present, check the oven |

|

| fan switch and wiring back to 3 amp fuse and then |

|

| back to power source if necessary. If 120 VAC is |

|

| present at L1 and L2, check both fuses on control |

|

| board (4A line) and (1A armature), check the VDC |

|

| output at terminals A+ and |

|

| at terminals L1 and L2, and DC voltage is present A+ |

|

| and |

|

| follows. |

| Conveyor Gear Motor | If DC voltage is present at A+ and |

|

| does not run, first check the mini breaker and then the |

|

| conveyor. Refer to the next possible cause. Check the |

|

| leads to the motor for evidence of any shorts or |

|

| opens, and each lead to ground. If the motor fails the |

|

| above tests, replace motor. From the top of the motor, |

|

| rotate motor shaft to determine if there is a locked |

|

| rotor or a locked gear box (use care so magnet and |

|

| the H.S. board are not damaged). Replace as needed. |

| Conveyor | Check for any mechanical |

|

| for worn bearings. A conveyor belt that is over |

|

| tightened may cause excessive bearing wear and |

|

| sometimes, irregular speed. |

Conveyor speed | Power Supply | Check power supply at the DC control board for the |

varying or intermittent |

| 120 VAC at board terminals L1 and L2 |

| D.C. Motor Control Board | Place the test meter probes on terminals A+ and |

|

| (With speed potentiometer set to maximum speed ( |

|

| Approx. 2 min.) The meter reading should be |

|

| approximately 100 VDC (±3%). The board output is |

|

| steady. If the board voltage output is unsteady beyond |

|

| limits (±3%) then the board is probably bad. Always |

|

| check the speed pot. , be sure it is okay before |

|

| changing a board. This test is not always 100% |

|

| accurate as this test is not performed at operating |

|

| speeds. However, this test is the best method |

|

| currently available. |

| DC Gearmotor | If the DC control board is steady then the problem |

|

| may be the motor or gearbox. Check the brushes in |

|

| the motor for excessive arching and/or unusual wear. |

|

| Check the motor and gearbox from instruction located |

|

| on page 14 under "possible cause" Listing "conveyor |

|

| gear motor." |

| Magnet | Check to insure that the magnet (cemented to shaft of |

|

| conveyor drive motor) has not been damaged, or |

|

| come loose from motor shaft. Replace as needed. |

| Hall Effect Sensor | Check for any physical damage to Hall Effect Sensor |

|

| (mounted on conveyor drive motor Check all wiring |

|

| and connections for damage. Check all connections |

|

| for tightness or proper location and check all wiring for |

|

| visible damage. Replace as needed. Connect new |

|

| Hall Effect to system and check for steady operation. |

MODELS 1456 - 1457- |

|

|

Oven will not heat | Gas Supply | Check for adequate gas supply to oven. |

| Manual Gas | Check to see that manual |

| Fan Switch | Check to see that the fan switch is on. |

| Main Oven Fan | Check if main oven fan is operating. If not, refer to |

|

| "Oven fan will not run." |

| Air Pressure Switch | Check for supply voltage on both sides of switch. If |

|

| voltage present on one side only, check for air tube |

|

| blockage or misalignment, adjust air switch. Replace |

|

| as needed. |

14 | Impinger I – 1400 Series Advantage Service Manual - Dom & Int’l |