OPERATION | ||

|

|

|

NOTE: If the unit fails to start turn Run/Stop switch to off and repeat step 3 through step 7 after waiting 30 seconds.

![]() CAUTION

CAUTION

•Do not allow the starter motor to run continuously for more than 20 seconds.

•Do not push the START button while the engine is running because this can damage the ring gear and/or the starter motor.

•IF the Engine Protection or battery Charging Lights do “not” turn off shortly after starting the engine shut off the engine immediately and

determine the cause.

NOTE: When starting for the first time, or after and extended period of time of not operating, it will take longer than normal to start because the fuel pump has to fill the fuel system. For best results, bleed the fuel system as indicated in Maintenance Section of this manual.

STOPPING THE ENGINE

Remove all welding and auxiliary power loads and allow the engine to run at low idle speed for a few minutes to cool the engine.

STOP the engine by placing the

NOTE: A fuel shut off valve is located on the fuel

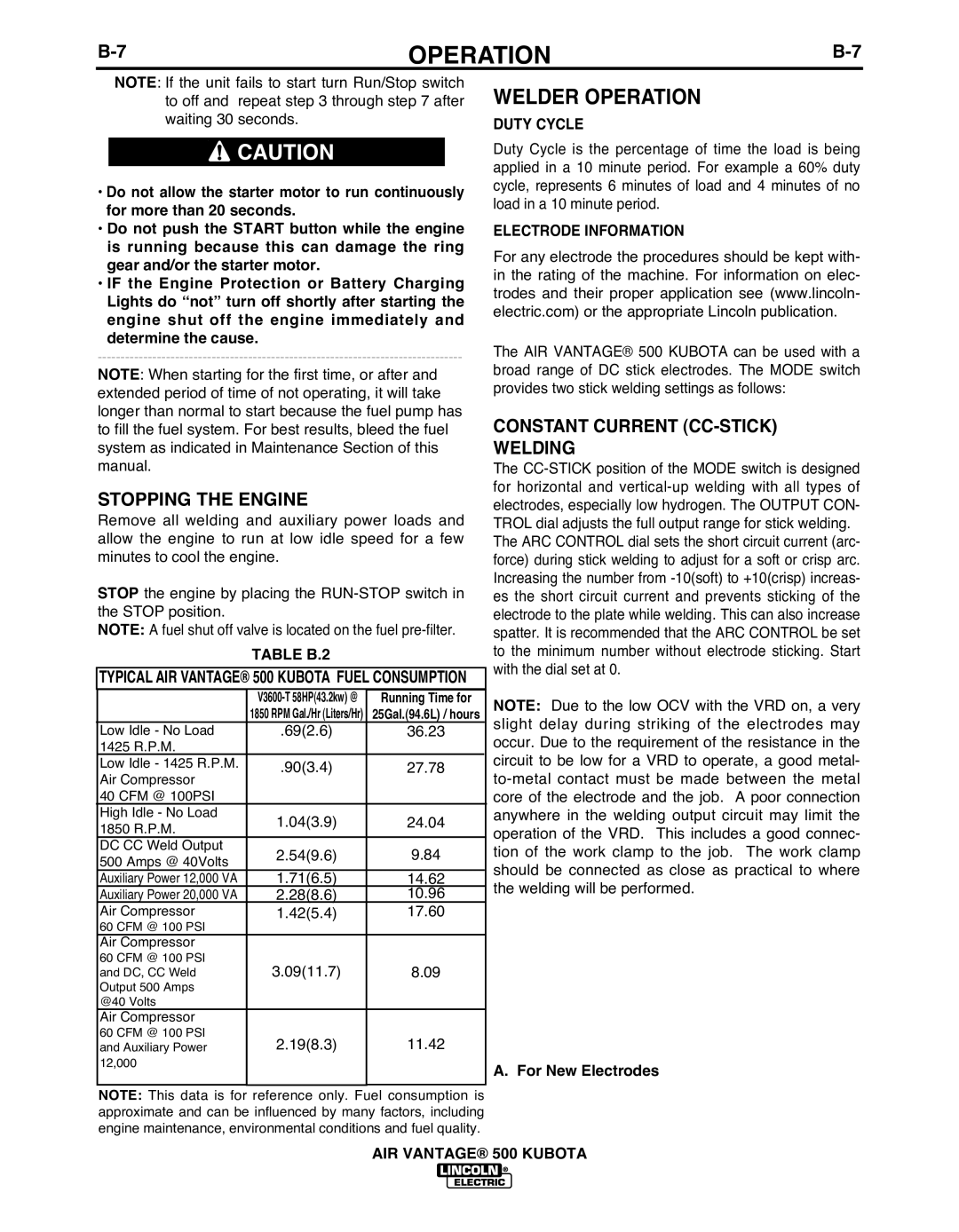

TAbLE b.2

TYPICAL AIR VANTAGE® 500 KUbOTA FUEL CONSUMPTION

| Running Time for |

| |

| 1850 RPM Gal./Hr (Liters/Hr) | 25Gal.(94.6L) / hours |

|

Low Idle - No Load | .69(2.6) | 36.23 |

|

1425 R.P.M. |

|

|

|

Low Idle - 1425 R.P.M. | .90(3.4) | 27.78 |

|

Air Compressor |

|

|

|

40 CFM @ 100PSI |

|

|

|

High Idle - No Load | 1.04(3.9) | 24.04 |

|

1850 R.P.M. |

| ||

|

|

| |

DC CC Weld Output | 2.54(9.6) | 9.84 |

|

500 Amps @ 40Volts |

| ||

|

|

| |

Auxiliary Power 12,000 VA | 1.71(6.5) | 14.62 |

|

Auxiliary Power 20,000 VA | 2.28(8.6) | 10.96 |

|

Air Compressor | 1.42(5.4) | 17.60 |

|

60 CFM @ 100 PSI |

|

|

|

Air Compressor |

|

|

|

60 CFM @ 100 PSI | 3.09(11.7) | 8.09 |

|

and DC, CC Weld |

| ||

Output 500 Amps |

|

|

|

@40 Volts |

|

|

|

Air Compressor |

|

|

|

60 CFM @ 100 PSI | 2.19(8.3) | 11.42 |

|

and Auxiliary Power |

| ||

12,000 |

|

|

|

|

|

|

|

NOTE: This data is for reference only. Fuel consumption is approximate and can be influenced by many factors, including engine maintenance, environmental conditions and fuel quality.

WELDER OPERATION

DUTY CYCLE

Duty Cycle is the percentage of time the load is being applied in a 10 minute period. For example a 60% duty cycle, represents 6 minutes of load and 4 minutes of no load in a 10 minute period.

ELECTRODE INFORMATION

For any electrode the procedures should be kept with- in the rating of the machine. For information on elec- trodes and their proper application see (www.lincoln- electric.com) or the appropriate Lincoln publication.

The AIR VANTAGE® 500 KUBOTA can be used with a broad range of DC stick electrodes. The MODE switch provides two stick welding settings as follows:

CONSTANT CURRENT (CC-STICK) WELDING

The

The ARC CONTROL dial sets the short circuit current (arc- force) during stick welding to adjust for a soft or crisp arc. Increasing the number from

NOTE: Due to the low OCV with the VRD on, a very slight delay during striking of the electrodes may occur. Due to the requirement of the resistance in the circuit to be low for a VRD to operate, a good metal-