PREVENTIVE MAINTENANCE

Although this oven has been designed to be as trouble free as possible, periodic Preventive Maintenance is essential to maintain peak performance. It is necessary to keep the motors, fans, and electronic controls free of dirt, dust and debris to insure proper cooling. Overheating is detrimental to the life of all components mentioned.

The periodic intervals for preventative cleaning may vary greatly depending upon the environment in which the oven is operating.

You must discuss the need for Preventive Maintenance with your Authorized Service Company to establish a proper program.

If there is any question the service company cannot answer, contact the Lincoln Foodservice Product, LLC Service Department.

CONCEPTS

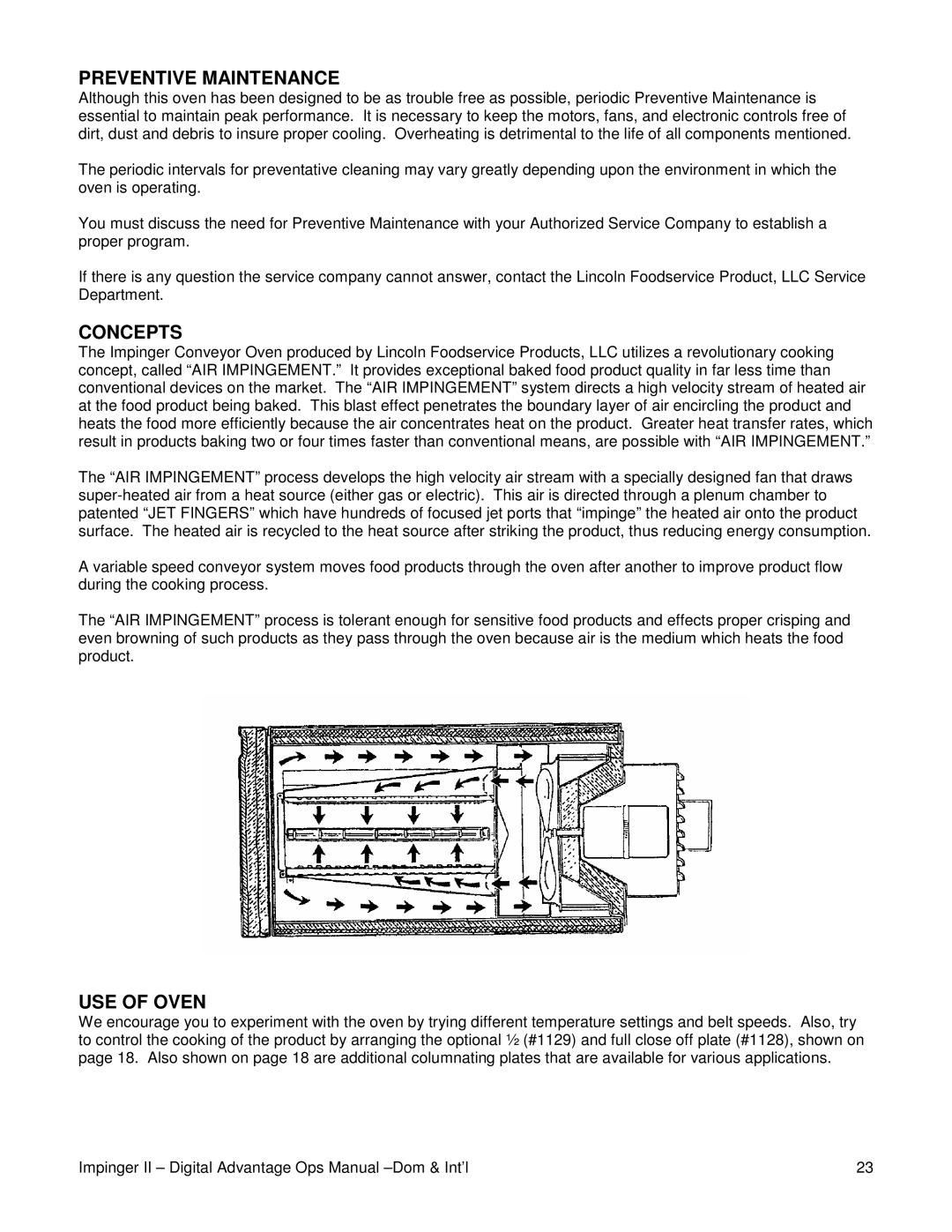

The Impinger Conveyor Oven produced by Lincoln Foodservice Products, LLC utilizes a revolutionary cooking concept, called “AIR IMPINGEMENT.” It provides exceptional baked food product quality in far less time than conventional devices on the market. The “AIR IMPINGEMENT” system directs a high velocity stream of heated air at the food product being baked. This blast effect penetrates the boundary layer of air encircling the product and heats the food more efficiently because the air concentrates heat on the product. Greater heat transfer rates, which result in products baking two or four times faster than conventional means, are possible with “AIR IMPINGEMENT.”

The “AIR IMPINGEMENT” process develops the high velocity air stream with a specially designed fan that draws

A variable speed conveyor system moves food products through the oven after another to improve product flow during the cooking process.

The “AIR IMPINGEMENT” process is tolerant enough for sensitive food products and effects proper crisping and even browning of such products as they pass through the oven because air is the medium which heats the food product.

USE OF OVEN

We encourage you to experiment with the oven by trying different temperature settings and belt speeds. Also, try to control the cooking of the product by arranging the optional ½ (#1129) and full close off plate (#1128), shown on page 18. Also shown on page 18 are additional columnating plates that are available for various applications.

Impinger II – Digital Advantage Ops Manual | 23 |