| TROUBLESHOOTING |

| ||||

|

|

|

|

|

|

|

| Observe all Safety Guidelines detailed througout this manual | |||||

|

|

|

|

|

|

|

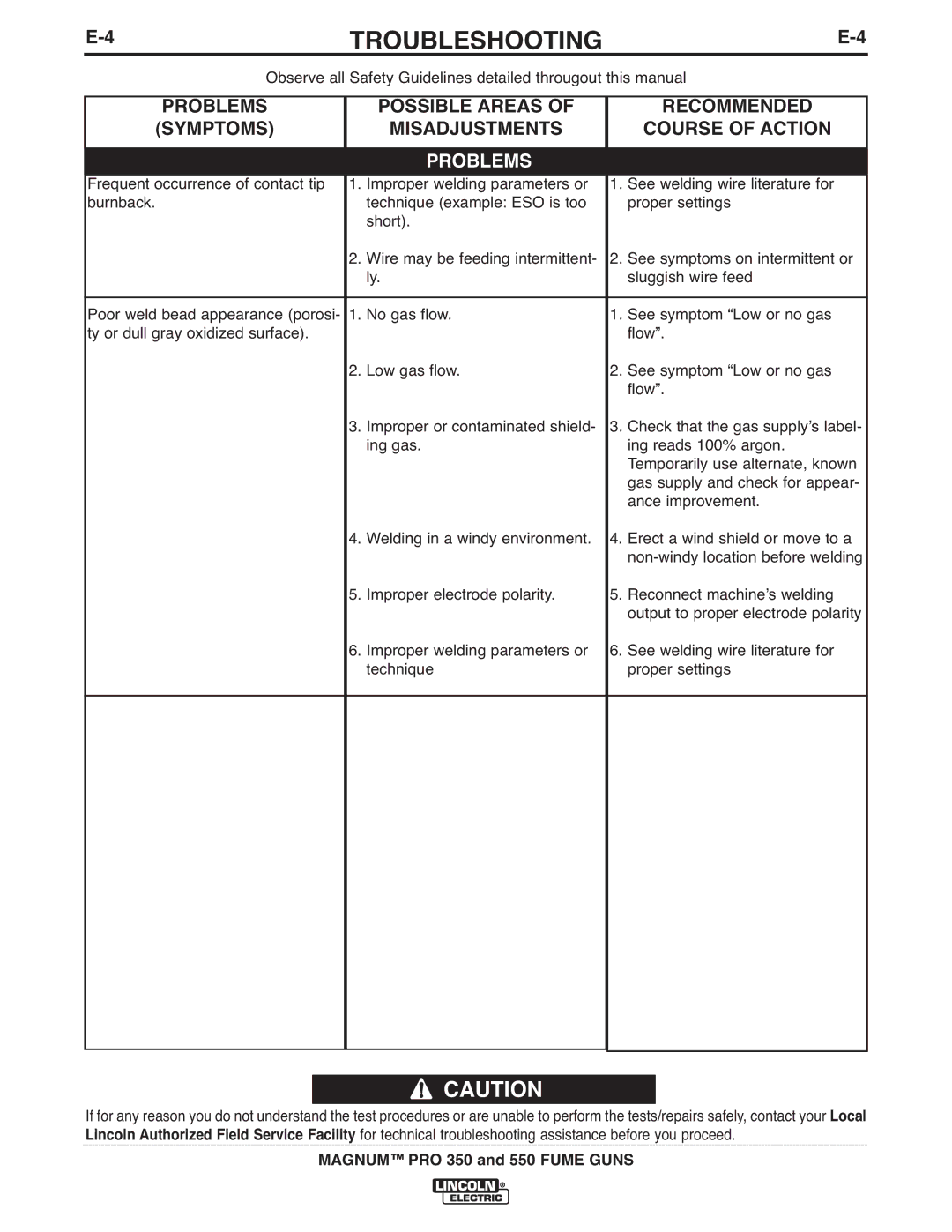

| PROBLEMS |

| POSSIBLE AREAS OF |

| RECOMMENDED |

|

| (SYMPTOMS) |

| MISADJUSTMENTS |

| COURSE OF ACTION |

|

|

|

| PROBLEMS |

|

|

|

Frequent occurrence of contact tip | 1. | Improper welding parameters or | 1. | See welding wire literature for |

| |

burnback. |

| technique (example: ESO is too |

| proper settings |

| |

|

|

| short). |

|

|

|

|

| 2. | Wire may be feeding intermittent- | 2. | See symptoms on intermittent or |

|

|

|

| ly. |

| sluggish wire feed |

|

|

|

|

|

|

| |

Poor weld bead appearance (porosi- | 1. | No gas flow. | 1. | See symptom “Low or no gas |

| |

ty or dull gray oxidized surface). |

|

|

| flow”. |

| |

|

| 2. | Low gas flow. | 2. | See symptom “Low or no gas |

|

|

|

|

|

| flow”. |

|

|

| 3. | Improper or contaminated shield- | 3. | Check that the gas supplyʼs label- |

|

|

|

| ing gas. |

| ing reads 100% argon. |

|

|

|

|

|

| Temporarily use alternate, known |

|

|

|

|

|

| gas supply and check for appear- |

|

|

|

|

|

| ance improvement. |

|

|

| 4. | Welding in a windy environment. | 4. Erect a wind shield or move to a |

| |

|

|

|

|

|

| |

|

| 5. | Improper electrode polarity. | 5. | Reconnect machineʼs welding |

|

|

|

|

|

| output to proper electrode polarity |

|

|

| 6. | Improper welding parameters or | 6. | See welding wire literature for |

|

|

|

| technique |

| proper settings |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

![]()

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.