| TROUBLESHOOTING |

|

|

| |||

|

|

|

|

|

|

|

|

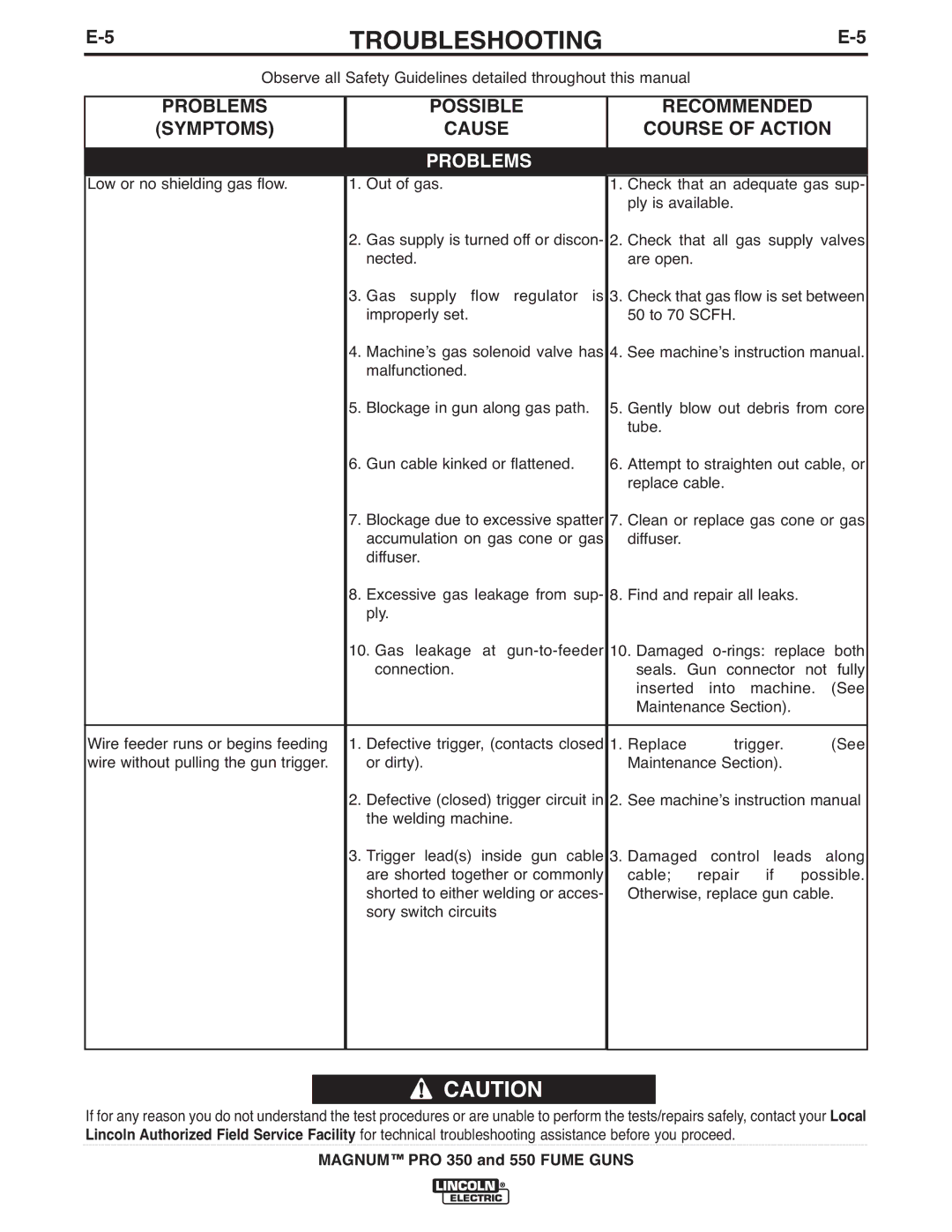

| Observe all Safety Guidelines detailed throughout this manual |

|

| ||||

|

|

|

|

|

|

| |

| PROBLEMS |

| POSSIBLE |

| RECOMMENDED |

| |

| (SYMPTOMS) |

| CAUSE |

| COURSE OF ACTION | ||

|

|

| PROBLEMS |

|

|

|

|

Low or no shielding gas flow. | 1. Out of gas. | 1. | Check that an adequate gas sup- | ||||

|

|

|

|

| ply is available. |

| |

|

| 2. | Gas supply is turned off or discon- | 2. | Check that all gas supply valves | ||

|

|

| nected. |

| are open. |

|

|

|

| 3. | Gas supply flow regulator is | 3. | Check that gas flow is set between | ||

|

|

| improperly set. |

| 50 to 70 SCFH. |

| |

|

| 4. | Machineʼs gas solenoid valve has | 4. | See machineʼs instruction manual. | ||

|

|

| malfunctioned. |

|

|

|

|

|

| 5. | Blockage in gun along gas path. | 5. | Gently blow out debris from core | ||

|

|

|

|

| tube. |

|

|

|

| 6. | Gun cable kinked or flattened. | 6. | Attempt to straighten out cable, or | ||

|

|

|

|

| replace cable. |

| |

|

| 7. | Blockage due to excessive spatter | 7. | Clean or replace gas cone or gas | ||

|

|

| accumulation on gas cone or gas |

| diffuser. |

|

|

|

|

| diffuser. |

|

|

|

|

|

| 8. | Excessive gas leakage from sup- | 8. | Find and repair all leaks. |

| |

|

|

| ply. |

|

|

|

|

|

| 10. Gas leakage at | 10. Damaged | both | |||

|

|

| connection. |

| seals. Gun connector not fully | ||

|

|

|

|

| inserted | into machine. | (See |

|

|

|

|

| Maintenance Section). |

| |

|

|

|

|

|

| ||

Wire feeder runs or begins feeding | 1. Defective trigger, (contacts closed | 1. | Replace | trigger. | (See | ||

wire without pulling the gun trigger. |

| or dirty). |

| Maintenance Section). |

| ||

2.Defective (closed) trigger circuit in 2. See machineʼs instruction manual the welding machine.

3.Trigger lead(s) inside gun cable 3. Damaged control leads along

are shorted together or commonly | cable; | repair | if | possible. |

shorted to either welding or acces- | Otherwise, replace gun cable. | |||

sory switch circuits |

|

|

|

|

![]()

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.