| TROUBLESHOOTING |

| |||

|

|

|

|

|

|

| Observe all Safety Guidelines detailed throughout this manual | ||||

|

|

|

|

|

|

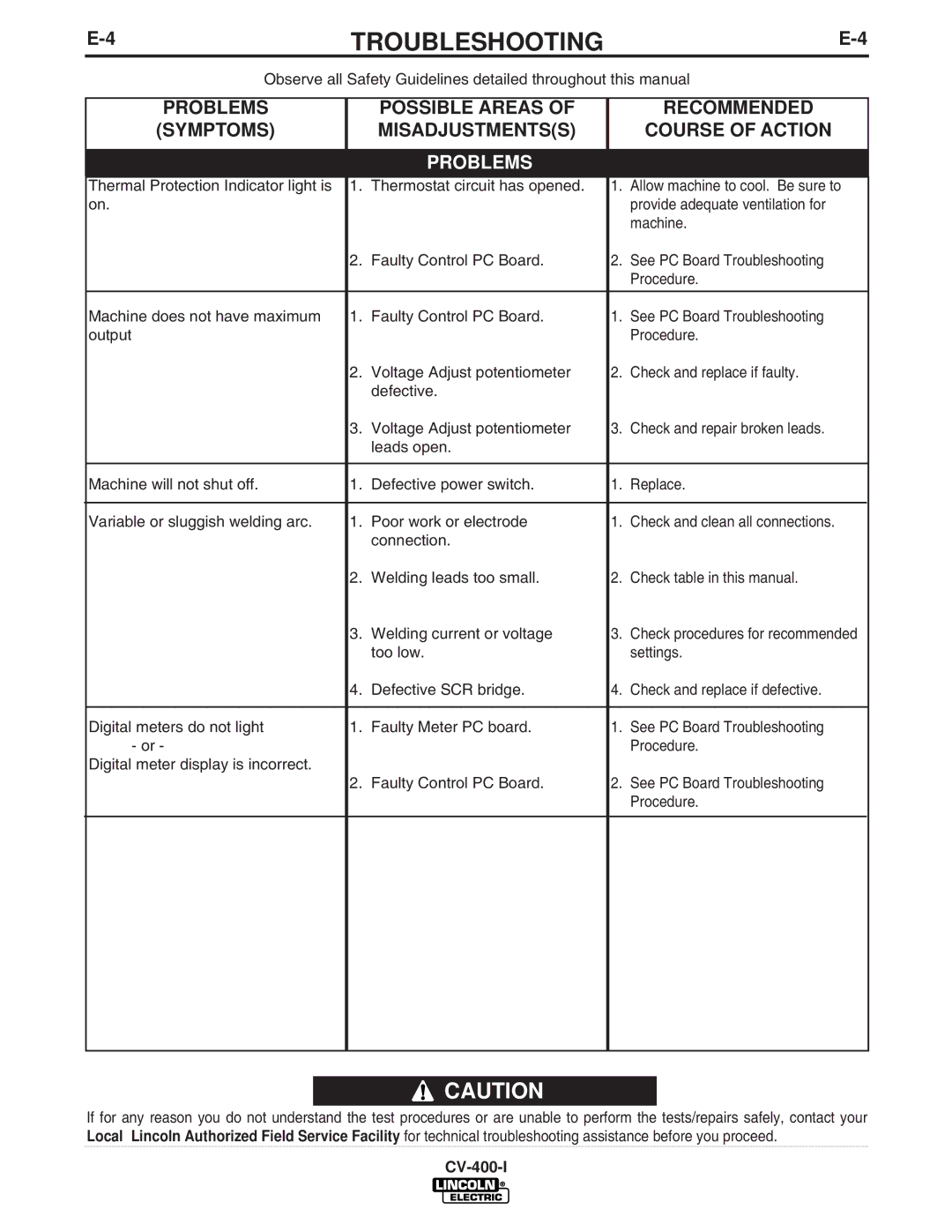

| PROBLEMS |

| POSSIBLE AREAS OF |

| RECOMMENDED |

| (SYMPTOMS) |

| MISADJUSTMENTS(S) |

| COURSE OF ACTION |

|

|

|

|

|

|

|

|

| PROBLEMS |

|

|

|

|

|

|

| |

Thermal Protection Indicator light is | 1. | Thermostat circuit has opened. | 1. | Allow machine to cool. Be sure to | |

on. |

|

|

| provide adequate ventilation for | |

|

|

|

|

| machine. |

|

| 2. | Faulty Control PC Board. | 2. | See PC Board Troubleshooting |

|

|

|

|

| Procedure. |

|

|

|

|

| |

Machine does not have maximum | 1. | Faulty Control PC Board. | 1. | See PC Board Troubleshooting | |

output |

|

|

| Procedure. | |

|

| 2. | Voltage Adjust potentiometer | 2. | Check and replace if faulty. |

|

|

| defective. |

|

|

|

| 3. | Voltage Adjust potentiometer | 3. | Check and repair broken leads. |

|

|

| leads open. |

|

|

|

|

|

|

| |

Machine will not shut off. | 1. | Defective power switch. | 1. | Replace. | |

|

|

|

|

| |

Variable or sluggish welding arc. | 1. | Poor work or electrode | 1. | Check and clean all connections. | |

|

|

| connection. |

|

|

|

| 2. | Welding leads too small. | 2. | Check table in this manual. |

|

| 3. | Welding current or voltage | 3. | Check procedures for recommended |

|

|

| too low. |

| settings. |

|

| 4. | Defective SCR bridge. | 4. | Check and replace if defective. |

|

|

|

|

| |

Digital meters do not light | 1. | Faulty Meter PC board. | 1. | See PC Board Troubleshooting | |

- or - |

|

|

| Procedure. | |

Digital meter display is incorrect. |

|

|

|

| |

|

| 2. | Faulty Control PC Board. | 2. | See PC Board Troubleshooting |

|

|

|

|

| Procedure. |

|

|

|

|

|

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.