| TROubLEShOOTING | |||

|

|

|

|

|

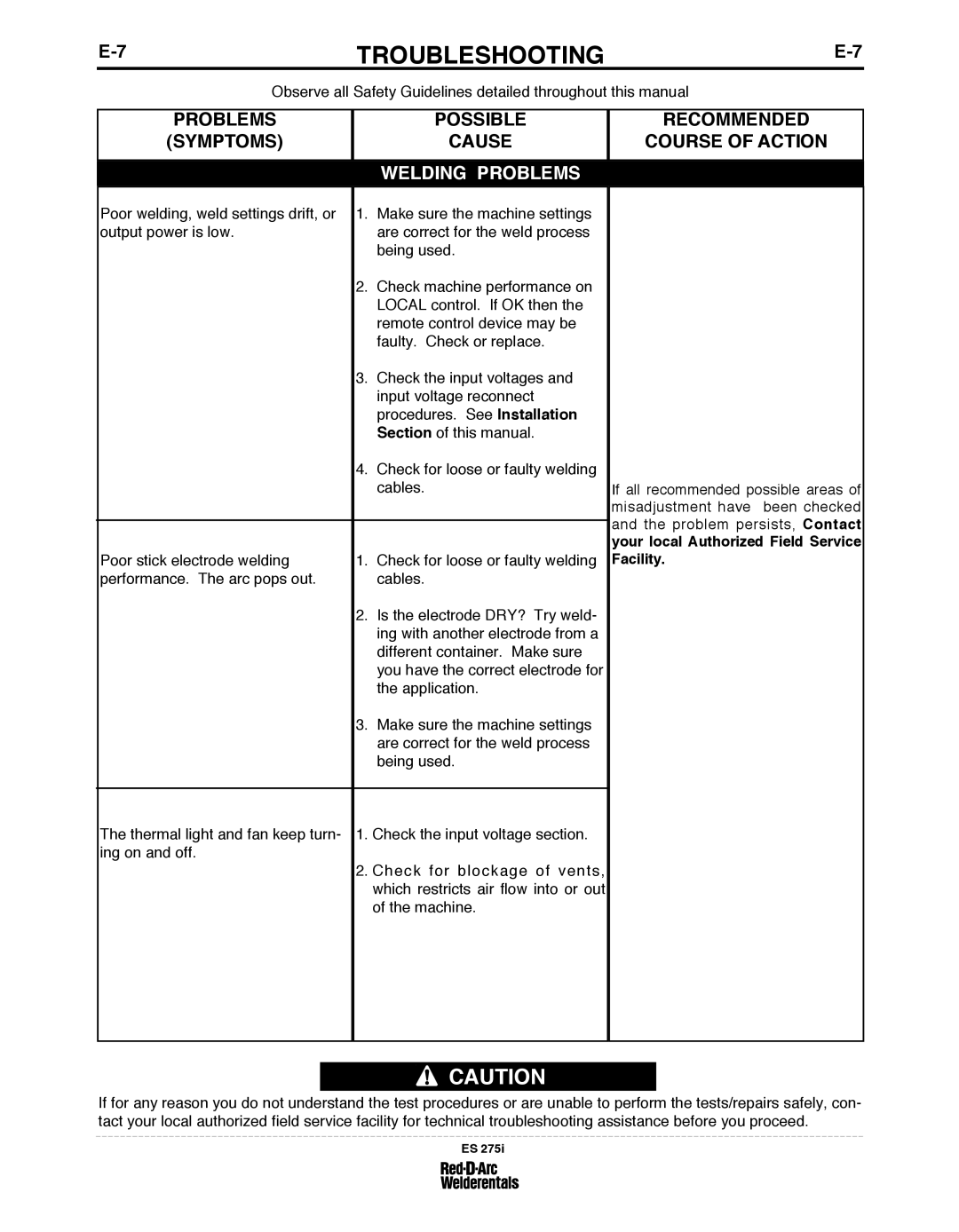

| Observe all Safety Guidelines detailed throughout this manual | |||

|

|

|

|

|

| PRObLEMS | POSSIbLE | RECOMMENDED |

|

| (SYMPTOMS) | CAuSE | COuRSE OF ACTION |

|

|

|

|

|

|

WELDING PRObLEMS

Poor welding, weld settings drift, or | 1. | Make sure the machine settings |

output power is low. |

| are correct for the weld process |

|

| being used. |

| 2. | Check machine performance on |

|

| LOCAL control. If OK then the |

|

| remote control device may be |

|

| faulty. Check or replace. |

| 3. | Check the input voltages and |

|

| input voltage reconnect |

|

| procedures. See Installation |

|

| Section of this manual. |

| 4. | Check for loose or faulty welding |

|

| cables. |

|

|

|

Poor stick electrode welding | 1. | Check for loose or faulty welding |

performance. The arc pops out. |

| cables. |

| 2. | Is the electrode DRY? Try weld- |

|

| ing with another electrode from a |

|

| different container. Make sure |

|

| you have the correct electrode for |

|

| the application. |

| 3. | Make sure the machine settings |

|

| are correct for the weld process |

|

| being used. |

|

| |

The thermal light and fan keep turn- | 1. Check the input voltage section. | |

ing on and off. |

|

|

| 2. Check for blockage of vents, | |

|

| which restricts air flow into or out |

|

| of the machine. |

|

|

|

If all recommended possible areas of misadjustment have been checked and the problem persists, Contact your local Authorized Field Service Facility.

![]() CAuTION

CAuTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, con- tact your local authorized field service facility for technical troubleshooting assistance before you proceed.

ES 275i