TROUBLESHOOTING | ||

|

|

|

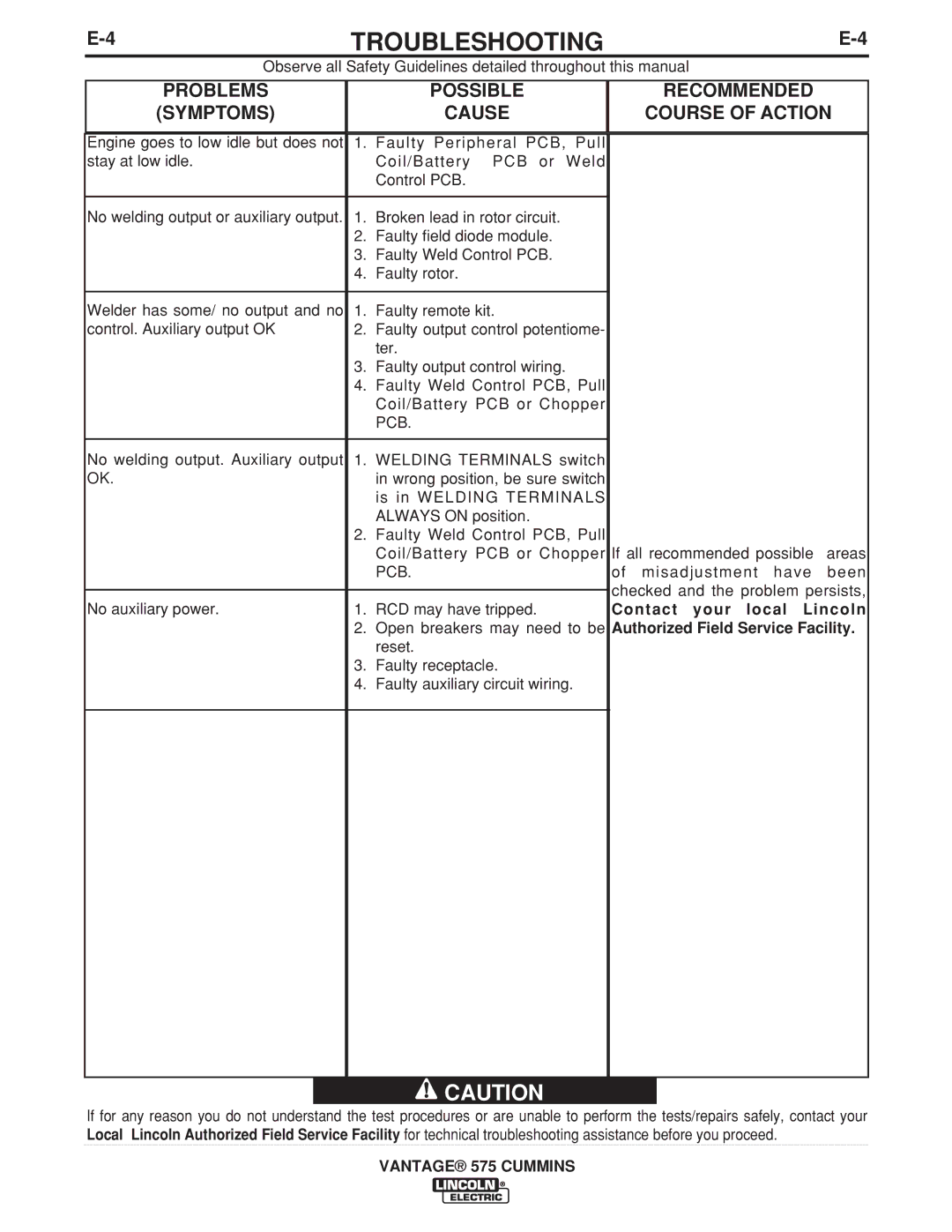

| Observe all Safety Guidelines detailed throughout this manual |

|

|

|

|

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Engine goes to low idle but does not | 1. Faulty Peripheral PCB, | Pull |

| ||

stay at low idle. |

| Coil/Battery PCB or | Weld |

| |

|

| Control PCB. |

|

|

|

|

|

|

| ||

No welding output or auxiliary output. 1. Broken lead in rotor circuit. |

|

|

| ||

| 2. | Faulty field diode module. |

|

|

|

| 3. | Faulty Weld Control PCB. |

|

|

|

| 4. | Faulty rotor. |

|

|

|

|

|

|

|

|

|

Welder has some/ no output and no | 1. | Faulty remote kit. |

|

|

|

control. Auxiliary output OK | 2. | Faulty output control potentiome- |

| ||

|

| ter. |

|

|

|

| 3. | Faulty output control wiring. |

|

|

|

| 4. | Faulty Weld Control PCB, Pull |

| ||

|

| Coil/Battery PCB or Chopper |

| ||

|

| PCB. |

|

|

|

|

|

|

| ||

No welding output. Auxiliary output | 1. WELDING TERMINALS switch |

| |||

OK. |

| in wrong position, be sure switch |

| ||

|

| is in WELDING TERMINALS |

| ||

|

| ALWAYS ON position. |

|

|

|

| 2. | Faulty Weld Control PCB, Pull |

| ||

|

| Coil/Battery PCB or Chopper If all recommended possible | areas | ||

|

| PCB. |

| of misadjustment have | been |

|

|

|

| checked and the problem persists, | |

|

|

|

| ||

No auxiliary power. | 1. | RCD may have tripped. |

| Contact your local Lincoln | |

| 2. | Open breakers may need to be Authorized Field Service Facility. | |||

|

| reset. |

|

|

|

| 3. | Faulty receptacle. |

|

|

|

| 4. | Faulty auxiliary circuit wiring. |

| ||

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

VANTAGE® 575 CUMMINS