OPERATION | ||

|

|

|

(See Customer Assistance Policy in the front of this Instruction Manual)

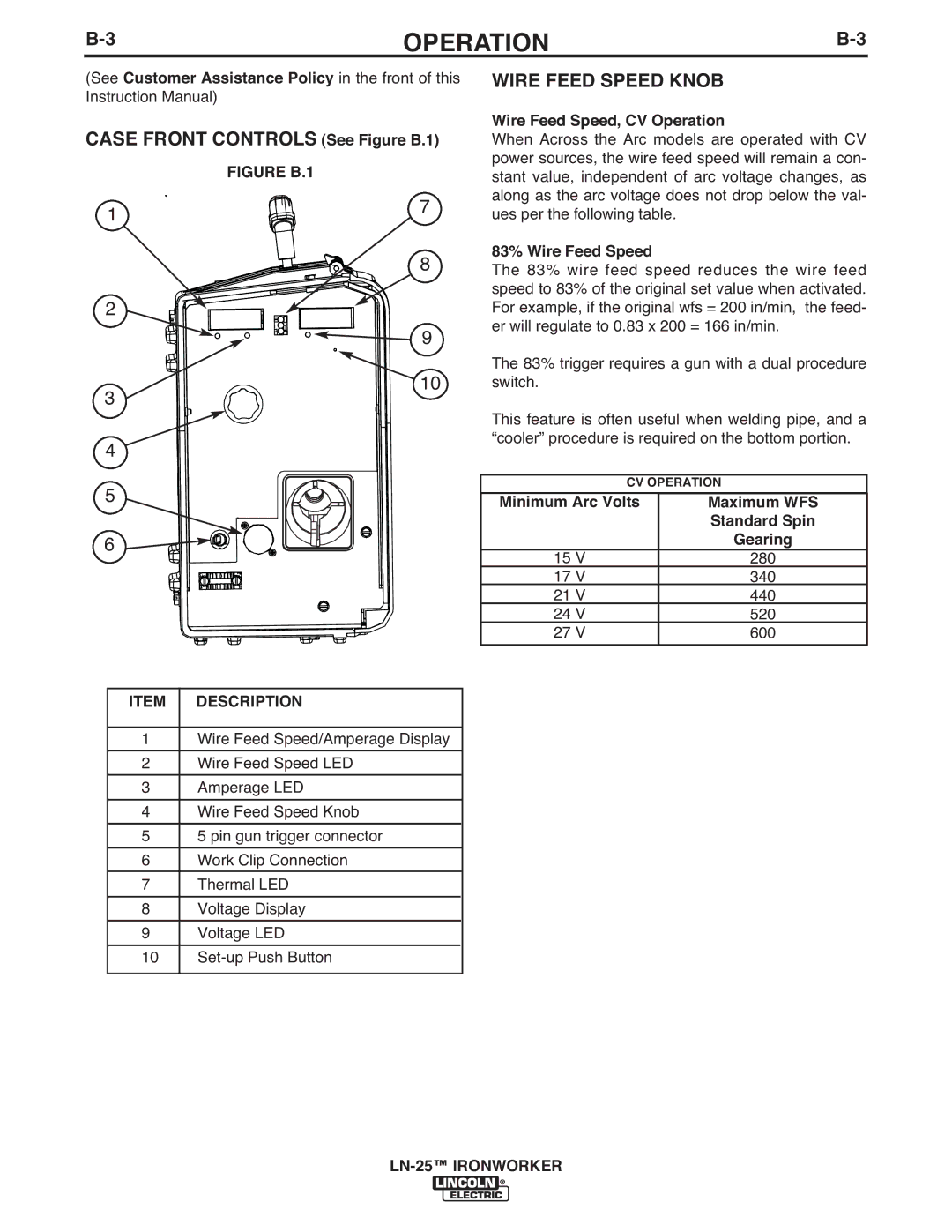

CASE FRONT CONTROLS (See Figure B.1)

| FIGURE B.1 |

1 | 7 |

|

8

2

9

![]()

![]()

![]() 10 3

10 3 ![]()

![]()

![]()

![]()

![]()

![]()

4

5

6

ITEM | DESCRIPTION |

|

|

1 | Wire Feed Speed/Amperage Display |

|

|

2 | Wire Feed Speed LED |

|

|

3 | Amperage LED |

|

|

4 | Wire Feed Speed Knob |

|

|

5 | 5 pin gun trigger connector |

|

|

6 | Work Clip Connection |

7 | Thermal LED |

|

|

8 | Voltage Display |

|

|

9 | Voltage LED |

|

|

10 | |

|

|

WIRE FEED SPEED KNOB

Wire Feed Speed, CV Operation

When Across the Arc models are operated with CV power sources, the wire feed speed will remain a con- stant value, independent of arc voltage changes, as along as the arc voltage does not drop below the val- ues per the following table.

83% Wire Feed Speed

The 83% wire feed speed reduces the wire feed speed to 83% of the original set value when activated. For example, if the original wfs = 200 in/min, the feed- er will regulate to 0.83 x 200 = 166 in/min.

The 83% trigger requires a gun with a dual procedure switch.

This feature is often useful when welding pipe, and a “cooler” procedure is required on the bottom portion.

CV OPERATION

Minimum Arc Volts | Maximum WFS |

| Standard Spin |

| Gearing |

15 V | 280 |

17 V | 340 |

21 V | 440 |

24 V | 520 |

27 V | 600 |

|

|