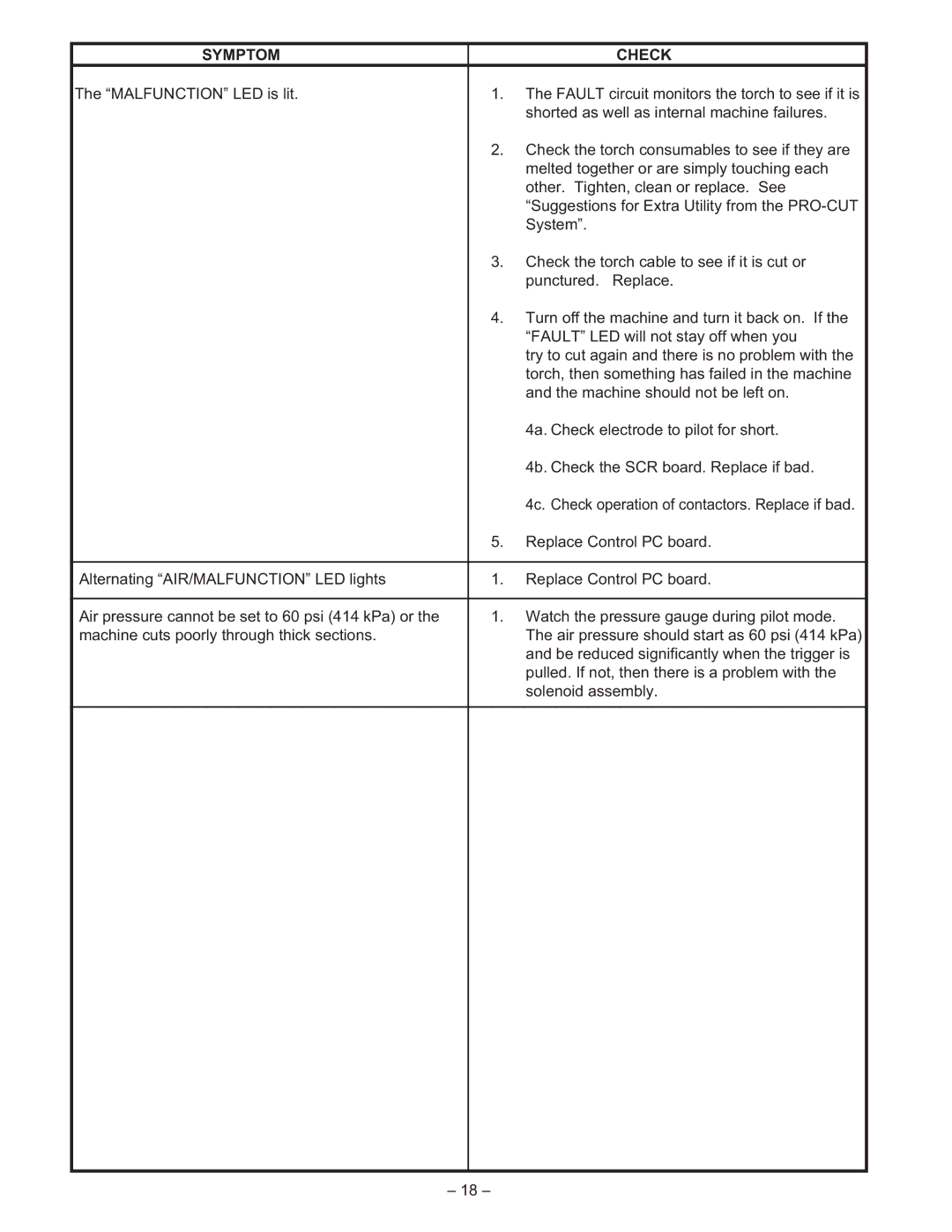

SYMPTOM |

| CHECK |

The “MALFUNCTION” LED is lit. | 1. | The FAULT circuit monitors the torch to see if it is |

|

| shorted as well as internal machine failures. |

| 2. | Check the torch consumables to see if they are |

|

| melted together or are simply touching each |

|

| other. Tighten, clean or replace. See |

|

| “Suggestions for Extra Utility from the |

|

| System”. |

| 3. | Check the torch cable to see if it is cut or |

|

| punctured. Replace. |

| 4. | Turn off the machine and turn it back on. If the |

|

| “FAULT” LED will not stay off when you |

|

| try to cut again and there is no problem with the |

|

| torch, then something has failed in the machine |

|

| and the machine should not be left on. |

|

| 4a. Check electrode to pilot for short. |

|

| 4b. Check the SCR board. Replace if bad. |

|

| 4c. Check operation of contactors. Replace if bad. |

| 5. | Replace Control PC board. |

|

|

|

Alternating “AIR/MALFUNCTION” LED lights | 1. | Replace Control PC board. |

|

|

|

Air pressure cannot be set to 60 psi (414 kPa) or the | 1. | Watch the pressure gauge during pilot mode. |

machine cuts poorly through thick sections. |

| The air pressure should start as 60 psi (414 kPa) |

|

| and be reduced significantly when the trigger is |

|

| pulled. If not, then there is a problem with the |

|

| solenoid assembly. |

|

|

|

|

|

|

– 18 –