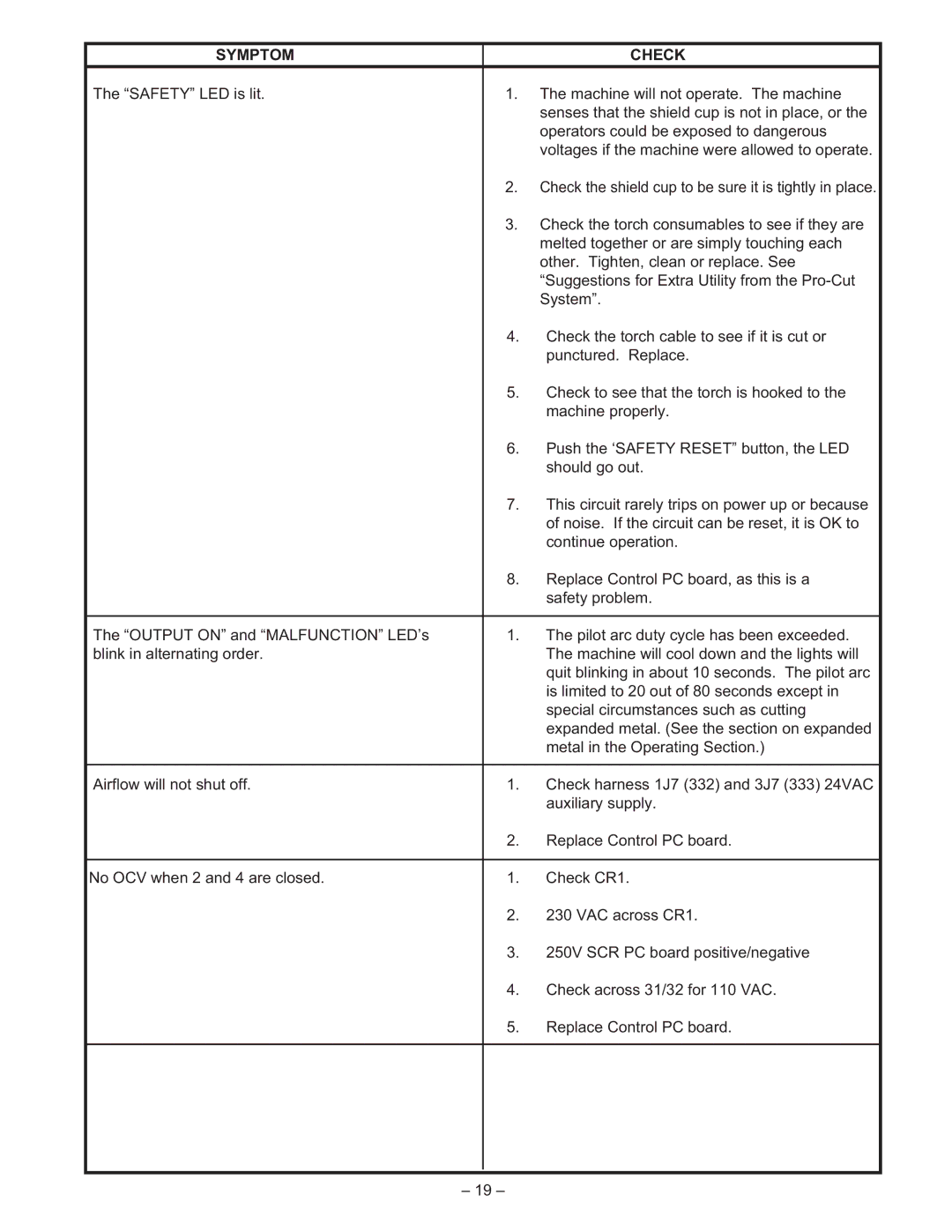

SYMPTOM |

| CHECK |

The “SAFETY” LED is lit. | 1. | The machine will not operate. The machine |

|

| senses that the shield cup is not in place, or the |

|

| operators could be exposed to dangerous |

|

| voltages if the machine were allowed to operate. |

| 2. | Check the shield cup to be sure it is tightly in place. |

| 3. | Check the torch consumables to see if they are |

|

| melted together or are simply touching each |

|

| other. Tighten, clean or replace. See |

|

| “Suggestions for Extra Utility from the |

|

| System”. |

| 4. | Check the torch cable to see if it is cut or |

|

| punctured. Replace. |

| 5. | Check to see that the torch is hooked to the |

|

| machine properly. |

| 6. | Push the ‘SAFETY RESET” button, the LED |

|

| should go out. |

| 7. | This circuit rarely trips on power up or because |

|

| of noise. If the circuit can be reset, it is OK to |

|

| continue operation. |

| 8. | Replace Control PC board, as this is a |

|

| safety problem. |

|

|

|

The “OUTPUT ON” and “MALFUNCTION” LED’s | 1. | The pilot arc duty cycle has been exceeded. |

blink in alternating order. |

| The machine will cool down and the lights will |

|

| quit blinking in about 10 seconds. The pilot arc |

|

| is limited to 20 out of 80 seconds except in |

|

| special circumstances such as cutting |

|

| expanded metal. (See the section on expanded |

|

| metal in the Operating Section.) |

|

|

|

Airflow will not shut off. | 1. | Check harness 1J7 (332) and 3J7 (333) 24VAC |

|

| auxiliary supply. |

| 2. | Replace Control PC board. |

|

|

|

No OCV when 2 and 4 are closed. | 1. | Check CR1. |

| 2. | 230 VAC across CR1. |

| 3. | 250V SCR PC board positive/negative |

| 4. | Check across 31/32 for 110 VAC. |

| 5. | Replace Control PC board. |

|

|

|

|

|

|

|

|

|

– 19 –