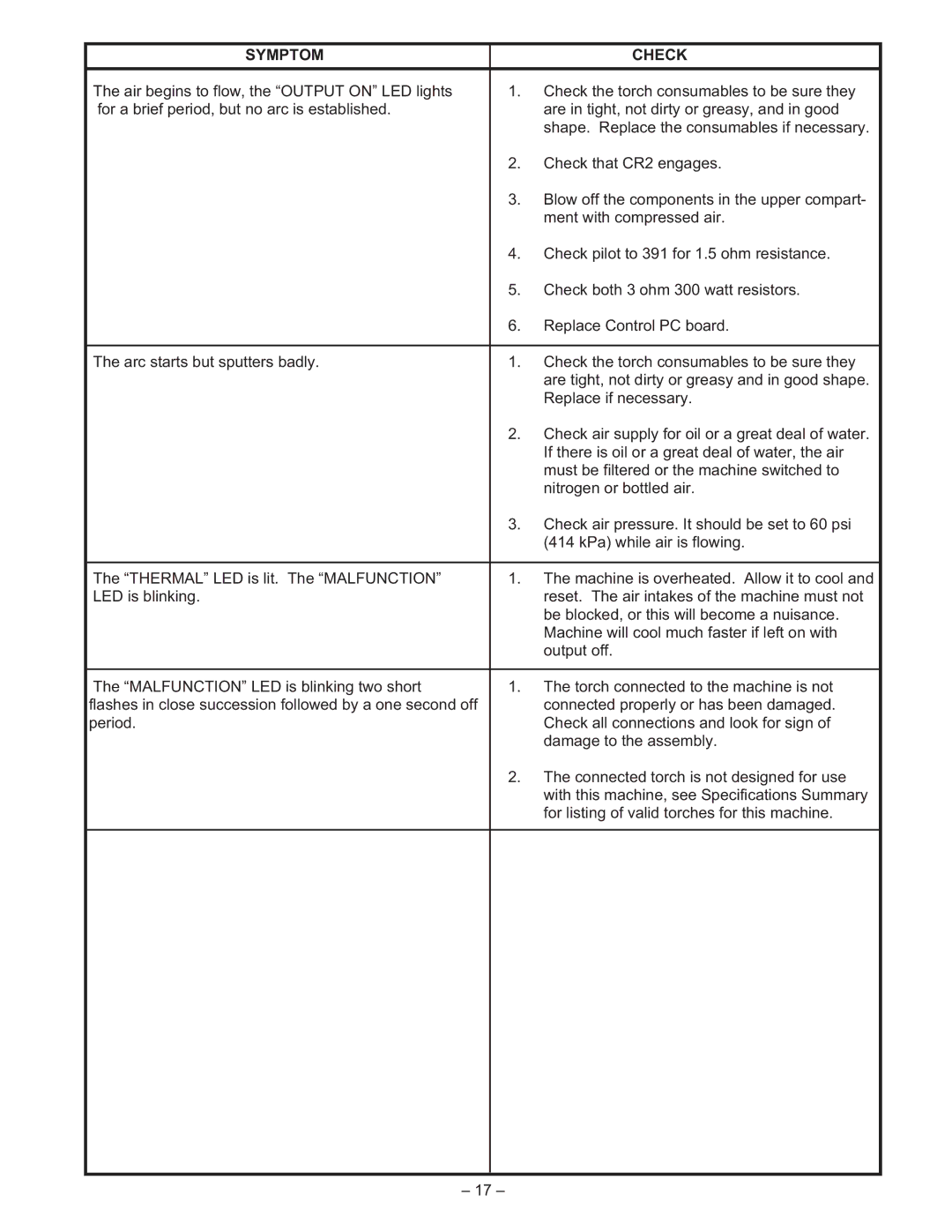

SYMPTOM |

| CHECK |

The air begins to flow, the “OUTPUT ON” LED lights | 1. | Check the torch consumables to be sure they |

for a brief period, but no arc is established. |

| are in tight, not dirty or greasy, and in good |

|

| shape. Replace the consumables if necessary. |

| 2. | Check that CR2 engages. |

| 3. | Blow off the components in the upper compart- |

|

| ment with compressed air. |

| 4. | Check pilot to 391 for 1.5 ohm resistance. |

| 5. | Check both 3 ohm 300 watt resistors. |

| 6. | Replace Control PC board. |

|

|

|

The arc starts but sputters badly. | 1. | Check the torch consumables to be sure they |

|

| are tight, not dirty or greasy and in good shape. |

|

| Replace if necessary. |

| 2. | Check air supply for oil or a great deal of water. |

|

| If there is oil or a great deal of water, the air |

|

| must be filtered or the machine switched to |

|

| nitrogen or bottled air. |

| 3. | Check air pressure. It should be set to 60 psi |

|

| (414 kPa) while air is flowing. |

|

|

|

The “THERMAL” LED is lit. The “MALFUNCTION” | 1. | The machine is overheated. Allow it to cool and |

LED is blinking. |

| reset. The air intakes of the machine must not |

|

| be blocked, or this will become a nuisance. |

|

| Machine will cool much faster if left on with |

|

| output off. |

|

|

|

The “MALFUNCTION” LED is blinking two short | 1. | The torch connected to the machine is not |

flashes in close succession followed by a one second off |

| connected properly or has been damaged. |

period. |

| Check all connections and look for sign of |

|

| damage to the assembly. |

| 2. | The connected torch is not designed for use |

|

| with this machine, see Specifications Summary |

|

| for listing of valid torches for this machine. |

|

|

|

|

|

|

– 17 –