INSTALLATION

4.Keep the torch in good repair and all connections tight to reduce high frequency leakage.

5.The work terminal must be connected to a ground within ten feet of the welder, using one of the

following methods:

a)A metal underground water pipe in direct contact with the earth for ten feet or more.

b)A 3/4” (19mm) galvanized pipe or a 5/8” (16mm) solid galvanized iron, steel or copper rod driven at least eight feet into the ground.

The ground should be securely made and the grounding cable should be as short as possible using cable of the same size as the work cable, or larger. Grounding to the building frame electrical conduit or a long pipe system can result in re- radiation, effectively making these members radiating antennas.

6.Keep all access panels and covers securely in place.

7.All electrical conductors within 50 ft (15.2m) of the welder should be enclosed in grounded rigid metallic conduit or equivalent shielding. Flexible metallic conduit is generally not suitable.

8.When the welder is enclosed in a metal building, several good earth driven electrical grounds (as in 5 (b) above) around the periphery of the building are recommended.

Failure to observe these recommended installation procedures can cause radio or TV interference problems and result in unsatisfactory welding performance resulting from lost high frequency power.

INPUT CONNECTIONS

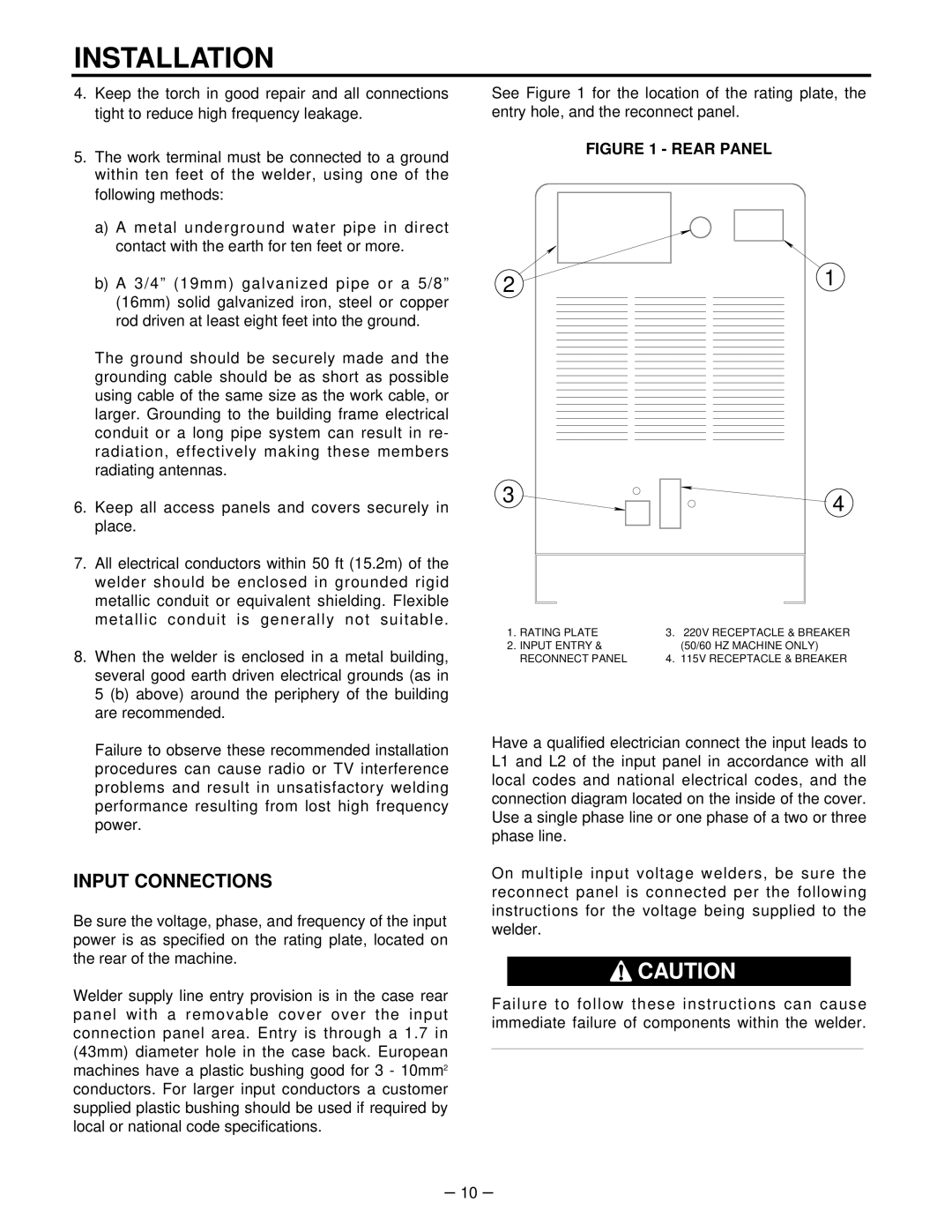

Be sure the voltage, phase, and frequency of the input power is as specified on the rating plate, located on the rear of the machine.

Welder supply line entry provision is in the case rear panel with a removable cover over the input connection panel area. Entry is through a 1.7 in (43mm) diameter hole in the case back. European machines have a plastic bushing good for 3 - 10mm2 conductors. For larger input conductors a customer supplied plastic bushing should be used if required by local or national code specifications.

See Figure 1 for the location of the rating plate, the entry hole, and the reconnect panel.

FIGURE 1 - REAR PANEL

2 | 1 |

|

3 | 4 |

|

1. RATING PLATE | 3. | 220V RECEPTACLE & BREAKER |

2. INPUT ENTRY & |

| (50/60 HZ MACHINE ONLY) |

RECONNECT PANEL | 4. | 115V RECEPTACLE & BREAKER |

Have a qualified electrician connect the input leads to L1 and L2 of the input panel in accordance with all local codes and national electrical codes, and the connection diagram located on the inside of the cover. Use a single phase line or one phase of a two or three phase line.

On multiple input voltage welders, be sure the reconnect panel is connected per the following instructions for the voltage being supplied to the welder.

![]() CAUTION

CAUTION

Failure to follow these instructions can cause immediate failure of components within the welder.

___________________________________________

– 10 –