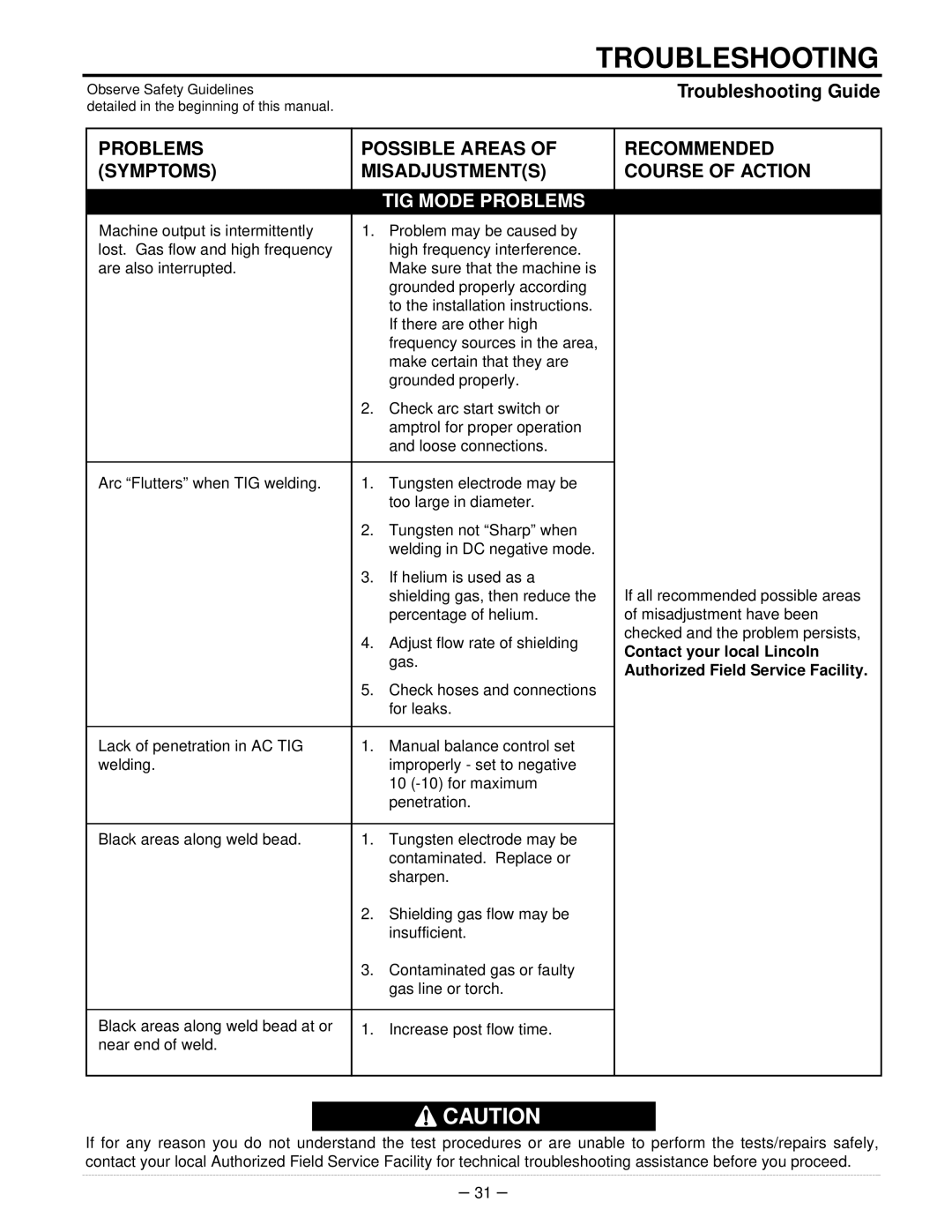

TROUBLESHOOTING

Observe Safety Guidelines

detailed in the beginning of this manual.

Troubleshooting Guide

|

|

|

|

|

|

|

| PROBLEMS |

|

| POSSIBLE AREAS OF |

| |

| (SYMPTOMS) |

|

| MISADJUSTMENT(S) |

| |

|

|

|

|

| TIG MODE PROBLEMS |

|

| Machine output is intermittently |

|

| 1. | Problem may be caused by |

|

| lost. Gas flow and high frequency |

|

|

| high frequency interference. |

|

| are also interrupted. |

|

|

| Make sure that the machine is |

|

|

|

|

|

| grounded properly according |

|

|

|

|

|

| to the installation instructions. |

|

|

|

|

|

| If there are other high |

|

|

|

|

|

| frequency sources in the area, |

|

|

|

|

|

| make certain that they are |

|

|

|

|

|

| grounded properly. |

|

|

|

|

| 2. | Check arc start switch or |

|

|

|

|

|

| amptrol for proper operation |

|

|

|

|

|

| and loose connections. |

|

|

|

|

|

|

|

|

| Arc “Flutters” when TIG welding. |

|

| 1. | Tungsten electrode may be |

|

|

|

|

|

| too large in diameter. |

|

|

|

|

| 2. | Tungsten not “Sharp” when |

|

|

|

|

|

| welding in DC negative mode. |

|

|

|

|

| 3. | If helium is used as a |

|

|

|

|

|

| shielding gas, then reduce the |

|

|

|

|

|

| percentage of helium. |

|

|

|

|

| 4. | Adjust flow rate of shielding |

|

|

|

|

|

| gas. |

|

|

|

|

| 5. | Check hoses and connections |

|

|

|

|

|

| for leaks. |

|

|

|

|

|

|

|

|

| Lack of penetration in AC TIG |

|

| 1. | Manual balance control set |

|

| welding. |

|

|

| improperly - set to negative |

|

|

|

|

|

| 10 |

|

|

|

|

|

| penetration. |

|

|

|

|

|

|

|

|

| Black areas along weld bead. |

|

| 1. | Tungsten electrode may be |

|

|

|

|

|

| contaminated. Replace or |

|

|

|

|

|

| sharpen. |

|

|

|

|

| 2. | Shielding gas flow may be |

|

|

|

|

|

| insufficient. |

|

|

|

|

| 3. | Contaminated gas or faulty |

|

|

|

|

|

| gas line or torch. |

|

|

|

|

|

|

|

|

| Black areas along weld bead at or |

|

| 1. | Increase post flow time. |

|

| near end of weld. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RECOMMENDED COURSE OF ACTION

If all recommended possible areas of misadjustment have been checked and the problem persists,

Contact your local Lincoln Authorized Field Service Facility.

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your local Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

– 31 –