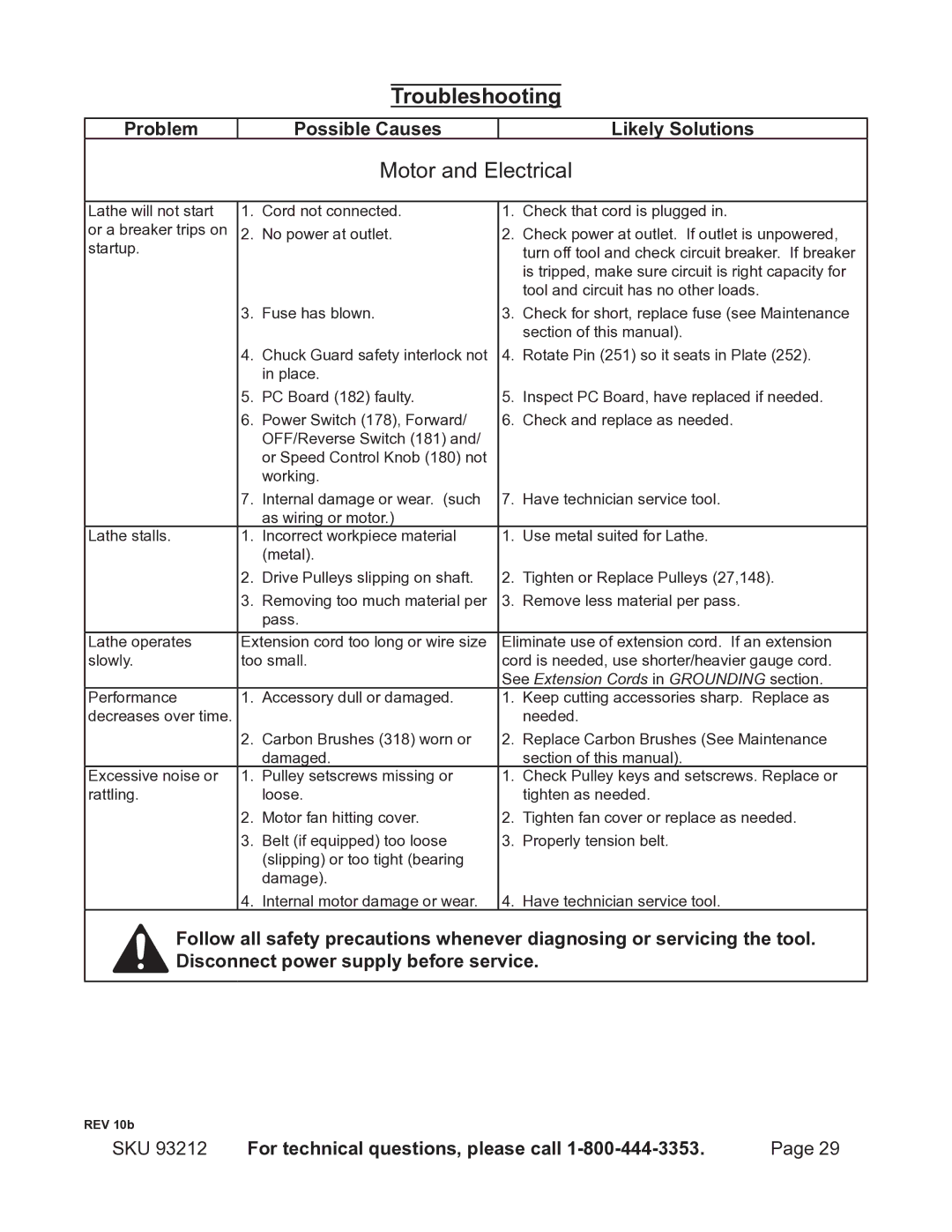

Troubleshooting

Problem

Possible Causes

Likely Solutions

Motor and Electrical

Lathe will not start | 1. | Cord not connected. | 1. | Check that cord is plugged in. |

or a breaker trips on | 2. | No power at outlet. | 2. | Check power at outlet. If outlet is unpowered, |

startup. |

|

|

| turn off tool and check circuit breaker. If breaker |

|

|

|

| is tripped, make sure circuit is right capacity for |

|

|

|

| tool and circuit has no other loads. |

| 3. | Fuse has blown. | 3. | Check for short, replace fuse (see Maintenance |

|

|

|

| section of this manual). |

| 4. | Chuck Guard safety interlock not | 4. | Rotate Pin (251) so it seats in Plate (252). |

|

| in place. |

|

|

| 5. | PC Board (182) faulty. | 5. | Inspect PC Board, have replaced if needed. |

| 6. | Power Switch (178), Forward/ | 6. | Check and replace as needed. |

|

| OFF/Reverse Switch (181) and/ |

|

|

|

| or Speed Control Knob (180) not |

|

|

|

| working. |

|

|

| 7. | Internal damage or wear. (such | 7. | Have technician service tool. |

|

| as wiring or motor.) |

|

|

Lathe stalls. | 1. | Incorrect workpiece material | 1. | Use metal suited for Lathe. |

|

| (metal). |

|

|

| 2. | Drive Pulleys slipping on shaft. | 2. | Tighten or Replace Pulleys (27,148). |

| 3. | Removing too much material per | 3. | Remove less material per pass. |

|

| pass. |

|

|

Lathe operates | Extension cord too long or wire size | Eliminate use of extension cord. If an extension | ||

slowly. | too small. | cord is needed, use shorter/heavier gauge cord. | ||

|

|

| See Extension Cords in GROUNDING section. | |

Performance | 1. Accessory dull or damaged. | 1. | Keep cutting accessories sharp. Replace as | |

decreases over time. |

|

|

| needed. |

| 2. | Carbon Brushes (318) worn or | 2. | Replace Carbon Brushes (See Maintenance |

|

| damaged. |

| section of this manual). |

Excessive noise or | 1. Pulley setscrews missing or | 1. | Check Pulley keys and setscrews. Replace or | |

rattling. |

| loose. |

| tighten as needed. |

| 2. | Motor fan hitting cover. | 2. | Tighten fan cover or replace as needed. |

| 3. | Belt (if equipped) too loose | 3. | Properly tension belt. |

|

| (slipping) or too tight (bearing |

|

|

|

| damage). |

|

|

| 4. | Internal motor damage or wear. | 4. | Have technician service tool. |

Follow all safety precautions whenever diagnosing or servicing the tool. Disconnect power supply before service.

REV 10b |

|

|

SKU 93212 | For technical questions, please call | Page 29 |