setting, and letting it run for several minutes at each setting before increasing to the next level. Continue until you’ve run the Lathe all the way up to the highest setting.

11.Turn the Power Switch OFF and wait for the Lathe to come to a complete stop.

12.Repeat the process with the H/L Gear Shift Lever at the High setting. Then repeat at both the Low, then High setting with the Forward/OFF/Reverse Switch in the Reverse position.

WARNING: THE MINI LATHE MUST BE COMPLETELY STOPPED BEFORE CHANGING THE FORWARD/OFF/ REVERSE SWITCH (181), THE FEED DIRECTION SELECTOR (35), OR THE GEAR SHIFT LEVER (33).

13.Turn the Power Switch off, the Speed Control Knob to 0 and unplug the Lathe.

14.Check the Compound Rest Crank (86b) and the Cross Slide Crank (86a) to see that the Compound Rest (105/108) and Cross Slide work properly. If they are too tight or too loose, adjust the Gibs (94/107) located at both crank sides (See Gib Adjustments in the Maintenance Section of this manual).

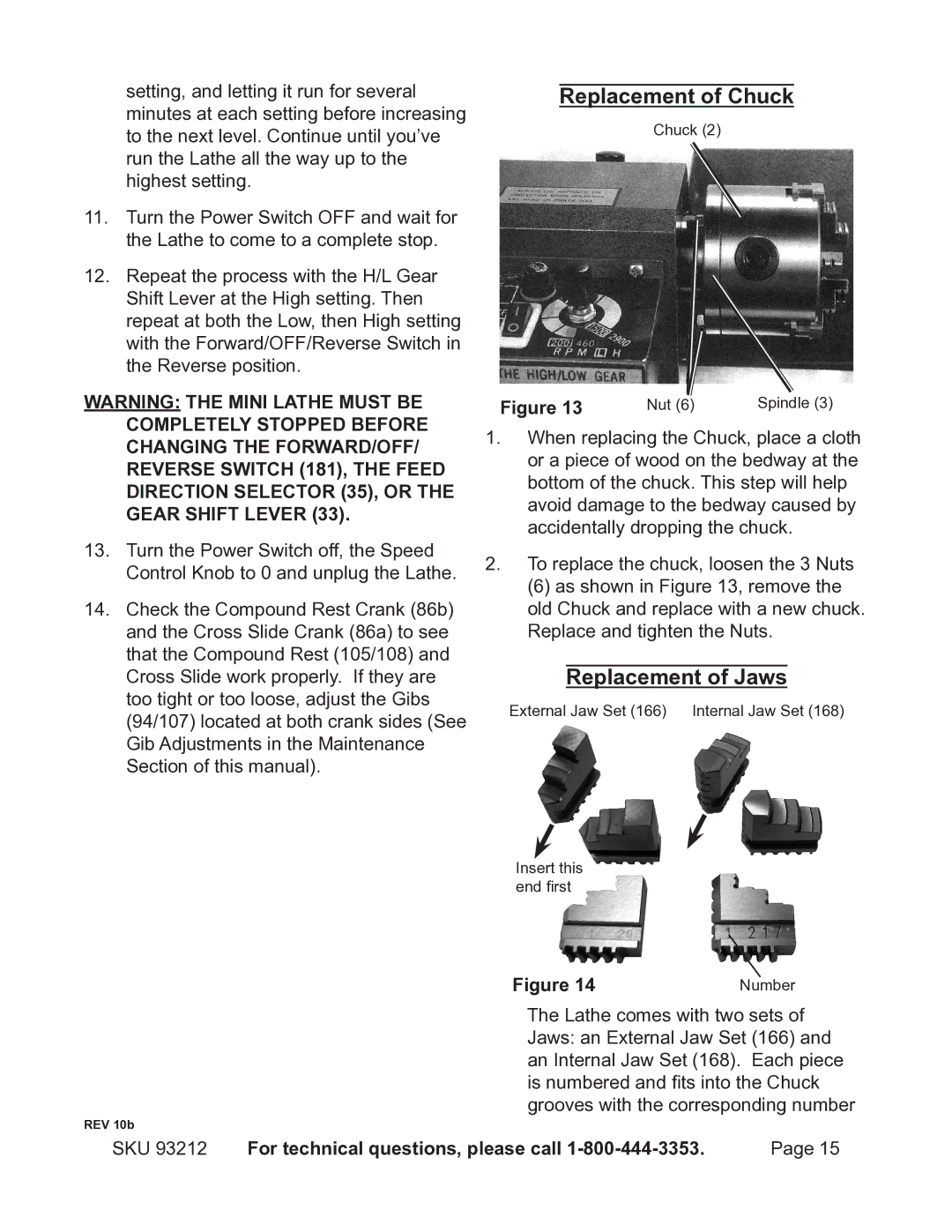

Replacement of Chuck

Chuck (2)

Figure 13 | Nut (6) | Spindle (3) |

1.When replacing the Chuck, place a cloth or a piece of wood on the bedway at the bottom of the chuck. This step will help avoid damage to the bedway caused by accidentally dropping the chuck.

2.To replace the chuck, loosen the 3 Nuts

(6) as shown in Figure 13, remove the old Chuck and replace with a new chuck. Replace and tighten the Nuts.

Replacement of Jaws

External Jaw Set (166) Internal Jaw Set (168)

Insert this end first

Figure 14 | Number |

The Lathe comes with two sets of Jaws: an External Jaw Set (166) and an Internal Jaw Set (168). Each piece is numbered and fits into the Chuck grooves with the corresponding number

REV 10b |

|

|

SKU 93212 | For technical questions, please call | Page 15 |