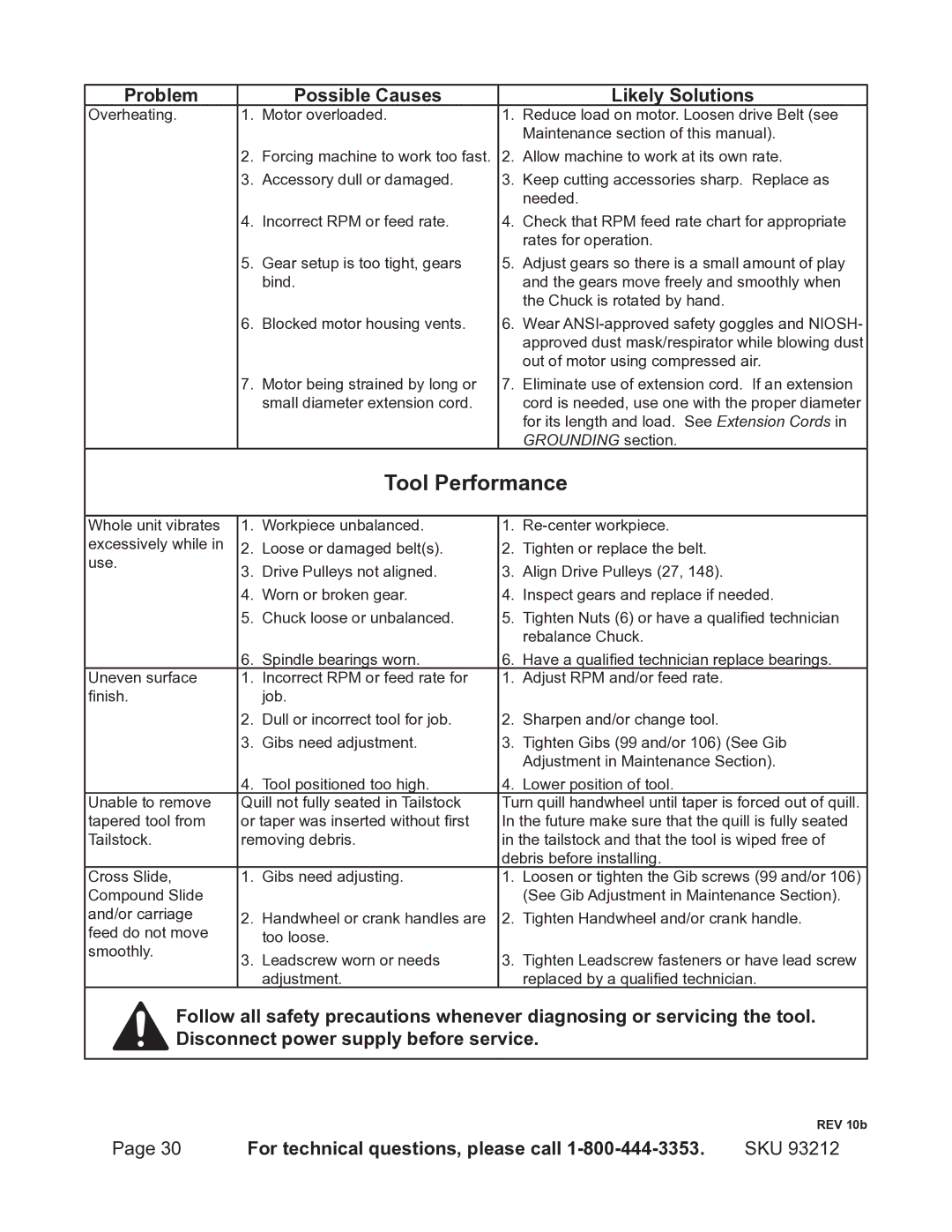

Problem |

| Possible Causes |

| Likely Solutions |

Overheating. | 1. Motor overloaded. | 1. | Reduce load on motor. Loosen drive Belt (see | |

|

|

|

| Maintenance section of this manual). |

| 2. | Forcing machine to work too fast. | 2. | Allow machine to work at its own rate. |

| 3. | Accessory dull or damaged. | 3. | Keep cutting accessories sharp. Replace as |

|

|

|

| needed. |

| 4. | Incorrect RPM or feed rate. | 4. | Check that RPM feed rate chart for appropriate |

|

|

|

| rates for operation. |

| 5. | Gear setup is too tight, gears | 5. | Adjust gears so there is a small amount of play |

|

| bind. |

| and the gears move freely and smoothly when |

|

|

|

| the Chuck is rotated by hand. |

| 6. | Blocked motor housing vents. | 6. | Wear |

|

|

|

| approved dust mask/respirator while blowing dust |

|

|

|

| out of motor using compressed air. |

| 7. | Motor being strained by long or | 7. | Eliminate use of extension cord. If an extension |

|

| small diameter extension cord. |

| cord is needed, use one with the proper diameter |

|

|

|

| for its length and load. See Extension Cords in |

|

|

|

| GROUNDING section. |

|

| Tool Performance | ||

|

|

|

| |

Whole unit vibrates | 1. Workpiece unbalanced. | 1. | ||

excessively while in | 2. | Loose or damaged belt(s). | 2. | Tighten or replace the belt. |

use. | 3. | Drive Pulleys not aligned. | 3. | Align Drive Pulleys (27, 148). |

| ||||

| 4. | Worn or broken gear. | 4. | Inspect gears and replace if needed. |

| 5. | Chuck loose or unbalanced. | 5. | Tighten Nuts (6) or have a qualified technician |

|

|

|

| rebalance Chuck. |

| 6. | Spindle bearings worn. | 6. | Have a qualified technician replace bearings. |

Uneven surface | 1. Incorrect RPM or feed rate for | 1. | Adjust RPM and/or feed rate. | |

finish. |

| job. |

|

|

| 2. | Dull or incorrect tool for job. | 2. | Sharpen and/or change tool. |

| 3. | Gibs need adjustment. | 3. | Tighten Gibs (99 and/or 106) (See Gib |

|

|

|

| Adjustment in Maintenance Section). |

| 4. | Tool positioned too high. | 4. | Lower position of tool. |

Unable to remove | Quill not fully seated in Tailstock | Turn quill handwheel until taper is forced out of quill. | ||

tapered tool from | or taper was inserted without first | In the future make sure that the quill is fully seated | ||

Tailstock. | removing debris. | in the tailstock and that the tool is wiped free of | ||

|

|

| debris before installing. | |

Cross Slide, | 1. Gibs need adjusting. | 1. | Loosen or tighten the Gib screws (99 and/or 106) | |

Compound Slide |

|

|

| (See Gib Adjustment in Maintenance Section). |

and/or carriage | 2. Handwheel or crank handles are | 2. | Tighten Handwheel and/or crank handle. | |

feed do not move |

| too loose. |

|

|

smoothly. | 3. | Leadscrew worn or needs | 3. | Tighten Leadscrew fasteners or have lead screw |

| ||||

|

| adjustment. |

| replaced by a qualified technician. |

Follow all safety precautions whenever diagnosing or servicing the tool. Disconnect power supply before service.

|

| REV 10b |

Page 30 | For technical questions, please call | SKU 93212 |