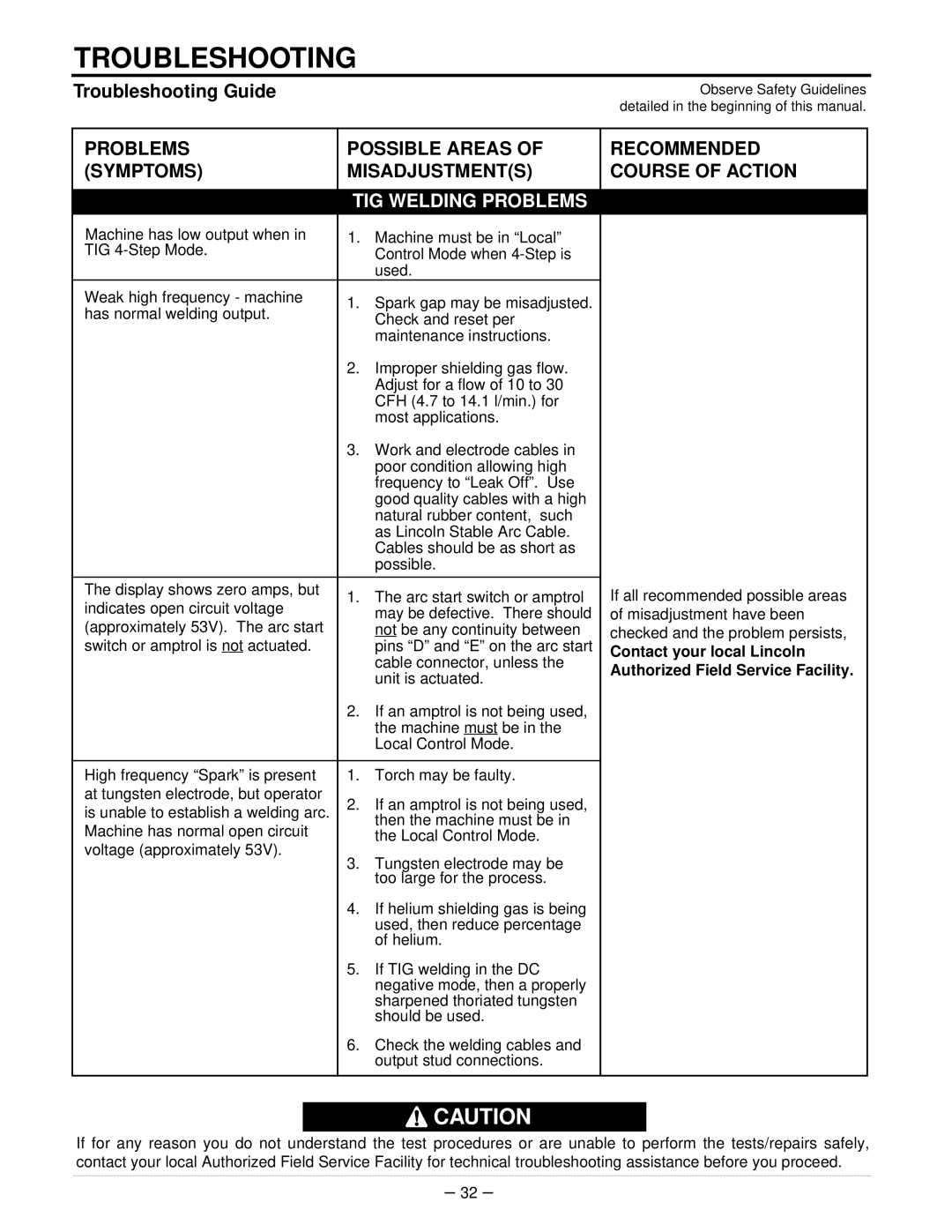

TROUBLESHOOTING

Troubleshooting Guide

Observe Safety Guidelines detailed in the beginning of this manual.

|

|

|

|

|

|

|

| PROBLEMS |

|

| POSSIBLE AREAS OF |

| |

| (SYMPTOMS) |

|

| MISADJUSTMENT(S) |

| |

|

|

|

| TIG WELDING PROBLEMS |

| |

| Machine has low output when in |

|

| 1. Machine must be in “Local” |

| |

| TIG |

|

|

| Control Mode when |

|

|

|

|

|

| used. |

|

| Weak high frequency - machine |

|

| 1. | Spark gap may be misadjusted. |

|

| has normal welding output. |

|

|

| ||

|

|

|

| Check and reset per |

| |

|

|

|

|

|

| |

|

|

|

|

| maintenance instructions. |

|

|

|

|

| 2. | Improper shielding gas flow. |

|

|

|

|

|

| Adjust for a flow of 10 to 30 |

|

|

|

|

|

| CFH (4.7 to 14.1 l/min.) for |

|

|

|

|

|

| most applications. |

|

|

|

|

| 3. | Work and electrode cables in |

|

|

|

|

|

| poor condition allowing high |

|

|

|

|

|

| frequency to “Leak Off”. Use |

|

|

|

|

|

| good quality cables with a high |

|

|

|

|

|

| natural rubber content, such |

|

|

|

|

|

| as Lincoln Stable Arc Cable. |

|

|

|

|

|

| Cables should be as short as |

|

|

|

|

|

| possible. |

|

|

|

|

|

|

|

|

| The display shows zero amps, but |

|

| 1. | The arc start switch or amptrol |

|

| indicates open circuit voltage |

|

|

| ||

|

|

|

| may be defective. There should |

| |

| (approximately 53V). The arc start |

|

|

|

| |

|

|

|

| not be any continuity between |

| |

| switch or amptrol is not actuated. |

|

|

| pins “D” and “E” on the arc start |

|

|

|

|

|

| cable connector, unless the |

|

|

|

|

|

| unit is actuated. |

|

|

|

|

| 2. | If an amptrol is not being used, |

|

|

|

|

|

| the machine must be in the |

|

|

|

|

|

| Local Control Mode. |

|

|

|

|

|

|

|

|

| High frequency “Spark” is present |

|

| 1. | Torch may be faulty. |

|

| at tungsten electrode, but operator |

|

| 2. | If an amptrol is not being used, |

|

| is unable to establish a welding arc. |

|

|

| ||

|

|

|

| then the machine must be in |

| |

| Machine has normal open circuit |

|

|

|

| |

|

|

|

| the Local Control Mode. |

| |

| voltage (approximately 53V). |

|

|

|

| |

|

|

| 3. | Tungsten electrode may be |

| |

|

|

|

|

| ||

|

|

|

|

| too large for the process. |

|

|

|

|

| 4. | If helium shielding gas is being |

|

|

|

|

|

| used, then reduce percentage |

|

|

|

|

|

| of helium. |

|

|

|

|

| 5. | If TIG welding in the DC |

|

|

|

|

|

| negative mode, then a properly |

|

|

|

|

|

| sharpened thoriated tungsten |

|

|

|

|

|

| should be used. |

|

|

|

|

| 6. | Check the welding cables and |

|

|

|

|

|

| output stud connections. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RECOMMENDED COURSE OF ACTION

If all recommended possible areas of misadjustment have been checked and the problem persists,

Contact your local Lincoln Authorized Field Service Facility.

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your local Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

– 32 –