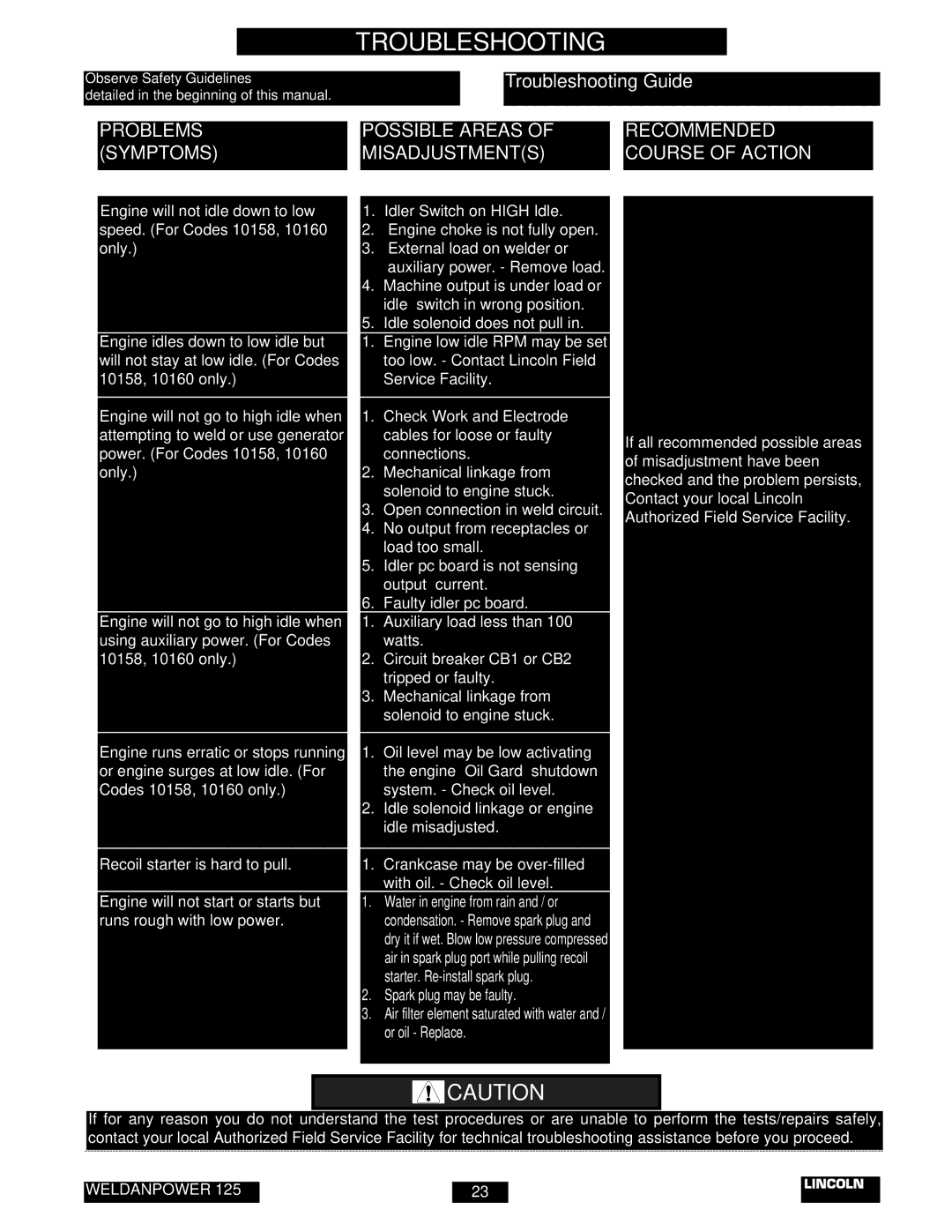

TROUBLESHOOTING

Observe Safety Guidelines

detailed in the beginning of this manual.

Troubleshooting Guide

|

|

|

|

|

|

|

|

|

| PROBLEMS |

|

| POSSIBLE AREAS OF |

| |

|

| (SYMPTOMS) |

|

| MISADJUSTMENT(S) |

| |

|

|

|

|

|

| ENGINE PROBLEMS |

|

|

| Engine will not idle down to low |

|

| 1. | Idler Switch on HIGH Idle. |

|

|

| speed. (For Codes 10158, 10160 |

|

| 2. | Engine choke is not fully open. |

|

|

| only.) |

|

| 3. | External load on welder or |

|

|

|

|

|

|

| auxiliary power. - Remove load. |

|

|

|

|

|

| 4. | Machine output is under load or |

|

|

|

|

|

|

| idle switch in wrong position. |

|

|

|

|

|

| 5. | Idle solenoid does not pull in. |

|

|

| Engine idles down to low idle but |

|

| 1. | Engine low idle RPM may be set |

|

|

| will not stay at low idle. (For Codes |

|

|

| too low. - Contact Lincoln Field |

|

|

| 10158, 10160 only.) |

|

|

| Service Facility. |

|

|

|

|

|

|

|

|

|

|

| Engine will not go to high idle when |

|

| 1. | Check Work and Electrode |

|

|

| attempting to weld or use generator |

|

|

| cables for loose or faulty |

|

|

| power. (For Codes 10158, 10160 |

|

|

| connections. |

|

|

| only.) |

|

| 2. | Mechanical linkage from |

|

|

|

|

|

|

| solenoid to engine stuck. |

|

|

|

|

|

| 3. | Open connection in weld circuit. |

|

|

|

|

|

| 4. | No output from receptacles or |

|

|

|

|

|

|

| load too small. |

|

|

|

|

|

| 5. | Idler pc board is not sensing |

|

|

|

|

|

|

| output current. |

|

|

|

|

|

| 6. | Faulty idler pc board. |

|

|

| Engine will not go to high idle when |

|

| 1. | Auxiliary load less than 100 |

|

|

| using auxiliary power. (For Codes |

|

|

| watts. |

|

|

| 10158, 10160 only.) |

|

| 2. | Circuit breaker CB1 or CB2 |

|

|

|

|

|

|

| tripped or faulty. |

|

|

|

|

|

| 3. | Mechanical linkage from |

|

|

|

|

|

|

| solenoid to engine stuck. |

|

|

|

|

|

|

|

|

|

|

| Engine runs erratic or stops running |

|

| 1. | Oil level may be low activating |

|

|

| or engine surges at low idle. (For |

|

|

| the engine “Oil Gard” shutdown |

|

|

| Codes 10158, 10160 only.) |

|

|

| system. - Check oil level. |

|

|

|

|

|

| 2. | Idle solenoid linkage or engine |

|

|

|

|

|

|

| idle misadjusted. |

|

|

|

|

|

|

|

|

|

|

| Recoil starter is hard to pull. |

|

| 1. | Crankcase may be |

|

|

|

|

|

|

| with oil. - Check oil level. |

|

|

| Engine will not start or starts but |

|

| 1. | Water in engine from rain and / or |

|

|

| runs rough with low power. |

|

|

| condensation. - Remove spark plug and |

|

|

|

|

|

|

| dry it if wet. Blow low pressure compressed |

|

|

|

|

|

|

| air in spark plug port while pulling recoil |

|

|

|

|

|

|

| starter. |

|

|

|

|

|

| 2. Spark plug may be faulty. |

| |

|

|

|

|

| 3. Air filter element saturated with water and / |

| |

|

|

|

|

|

| or oil - Replace. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RECOMMENDED COURSE OF ACTION

If all recommended possible areas of misadjustment have been checked and the problem persists,

Contact your local Lincoln Authorized Field Service Facility.

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your local Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

WELDANPOWER 125 | – 23 – |