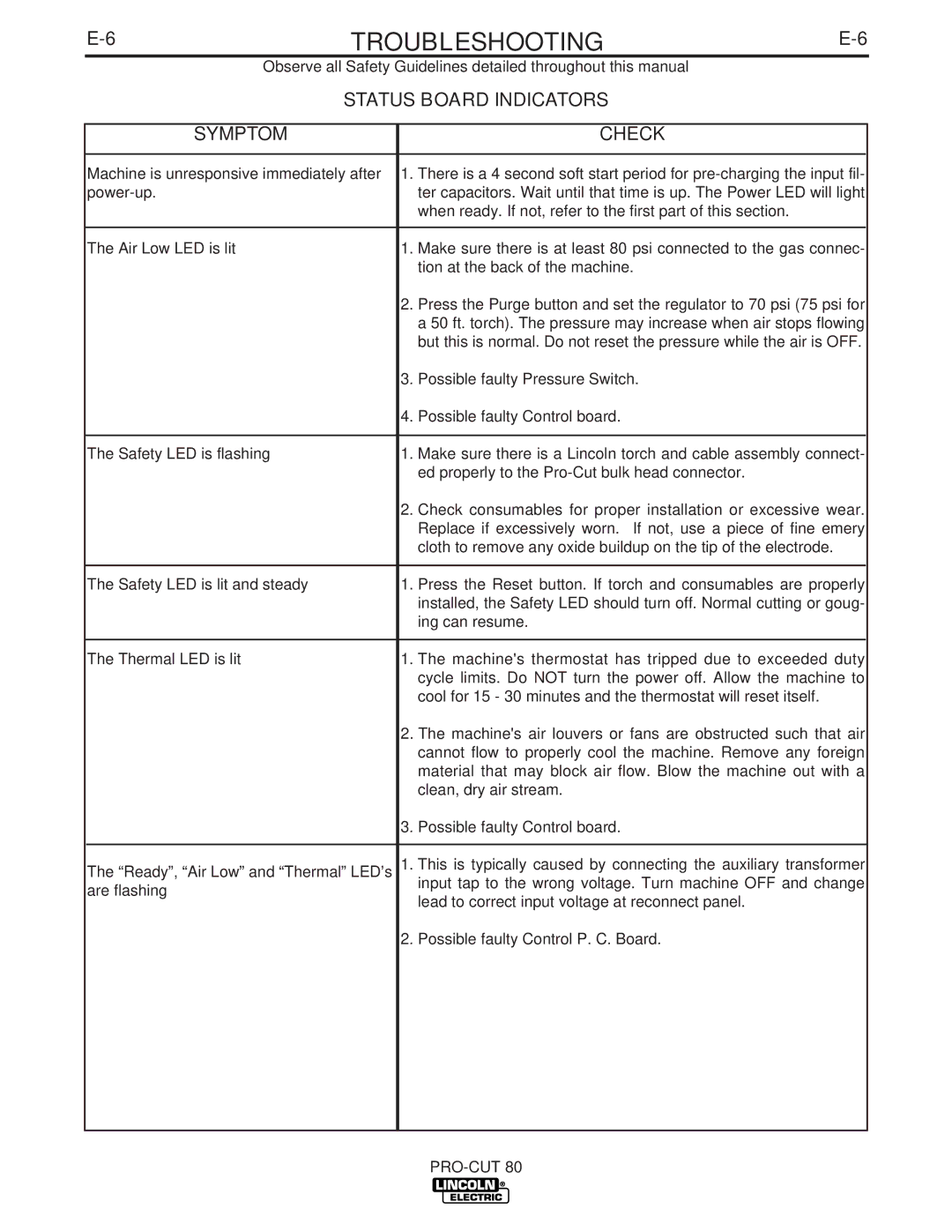

| TROUBLESHOOTING | ||||

|

|

|

|

|

|

| Observe all Safety Guidelines detailed throughout this manual |

| |||

|

|

|

|

| |

|

| STATUS BOARD INDICATORS |

| ||

|

|

|

|

|

|

| SYMPTOM |

|

| CHECK |

|

|

|

| |||

Machine is unresponsive immediately after | 1. | There is a 4 second soft start period for | |||

|

| ter capacitors. Wait until that time is up. The Power LED will light | |||

|

|

|

| when ready. If not, refer to the first part of this section. |

|

|

|

|

| ||

The Air Low LED is lit |

| 1. | Make sure there is at least 80 psi connected to the gas connec- | ||

|

|

|

| tion at the back of the machine. |

|

|

|

| 2. | Press the Purge button and set the regulator to 70 psi (75 psi for | |

|

|

|

| a 50 ft. torch). The pressure may increase when air stops flowing | |

|

|

|

| but this is normal. Do not reset the pressure while the air is OFF. | |

|

|

| 3. | Possible faulty Pressure Switch. |

|

|

|

| 4. | Possible faulty Control board. |

|

|

|

|

| ||

The Safety LED is flashing |

| 1. | Make sure there is a Lincoln torch and cable assembly connect- | ||

|

|

|

| ed properly to the |

|

|

|

| 2. | Check consumables for proper installation or excessive wear. | |

|

|

|

| Replace if excessively worn. If not, use a piece of fine emery | |

|

|

|

| cloth to remove any oxide buildup on the tip of the electrode. |

|

|

|

|

| ||

The Safety LED is lit and steady |

| 1. | Press the Reset button. If torch and consumables are properly | ||

|

|

|

| installed, the Safety LED should turn off. Normal cutting or goug- | |

|

|

|

| ing can resume. |

|

|

|

|

| ||

The Thermal LED is lit |

| 1. | The machine's thermostat has tripped due to exceeded duty | ||

|

|

|

| cycle limits. Do NOT turn the power off. Allow the machine to | |

|

|

|

| cool for 15 - 30 minutes and the thermostat will reset itself. |

|

|

|

| 2. | The machine's air louvers or fans are obstructed such that air | |

|

|

|

| cannot flow to properly cool the machine. Remove any foreign | |

|

|

|

| material that may block air flow. Blow the machine out with a | |

|

|

|

| clean, dry air stream. |

|

|

|

| 3. | Possible faulty Control board. |

|

|

|

| |||

The “Ready”, “Air Low” and “Thermal” LED’s | 1. | This is typically caused by connecting the auxiliary transformer | |||

are flashing |

|

| input tap to the wrong voltage. Turn machine OFF and change | ||

|

| lead to correct input voltage at reconnect panel. |

| ||

|

|

|

|

| |

|

|

| 2. | Possible faulty Control P. C. Board. |

|

|

|

|

|

|

|