OPERATION | ||

|

|

|

PILOT ARC DISCUSSION

The

When the pilot arc is started, a slight impulse will be felt in the torch handle. This occurrence is normal and is the mechanism which starts the plasma arc. This impulse can also be used to help troubleshoot a "no start" condition.

PROCEDURE RECOMMENDATIONS

When properly used, plasma arc cutting or gouging is a very economical process. Improper use will result in a very high operating cost.

General - In All Cases

•Follow safety precautions as printed throughout this operating manual and on the machine.

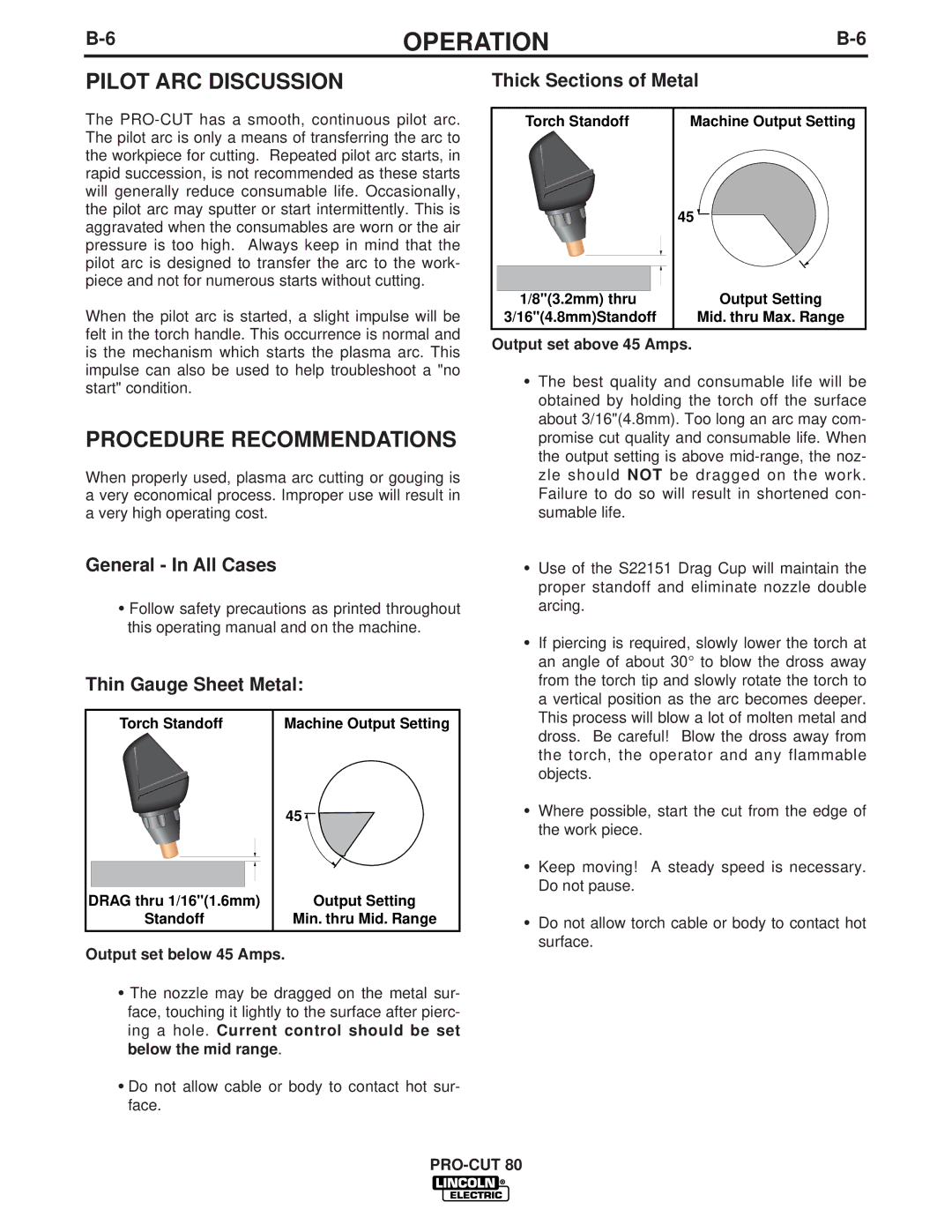

Thin Gauge Sheet Metal:

Torch Standoff | Machine Output Setting |

45 ![]()

DRAG thru 1/16"(1.6mm) | Output Setting |

Standoff | Min. thru Mid. Range |

Output set below 45 Amps.

•The nozzle may be dragged on the metal sur- face, touching it lightly to the surface after pierc- ing a hole. Current control should be set below the mid range.

•Do not allow cable or body to contact hot sur- face.

Thick Sections of Metal

Torch Standoff | Machine Output Setting |

45 ![]()

1/8"(3.2mm) thru | Output Setting |

3/16"(4.8mm)Standoff | Mid. thru Max. Range |

Output set above 45 Amps.

•The best quality and consumable life will be obtained by holding the torch off the surface about 3/16"(4.8mm). Too long an arc may com- promise cut quality and consumable life. When the output setting is above

•Use of the S22151 Drag Cup will maintain the proper standoff and eliminate nozzle double arcing.

•If piercing is required, slowly lower the torch at an angle of about 30° to blow the dross away from the torch tip and slowly rotate the torch to a vertical position as the arc becomes deeper. This process will blow a lot of molten metal and dross. Be careful! Blow the dross away from the torch, the operator and any flammable objects.

•Where possible, start the cut from the edge of the work piece.

•Keep moving! A steady speed is necessary. Do not pause.

•Do not allow torch cable or body to contact hot surface.