OPERATION | ||

|

|

|

CUTTING CAPABILITY

The

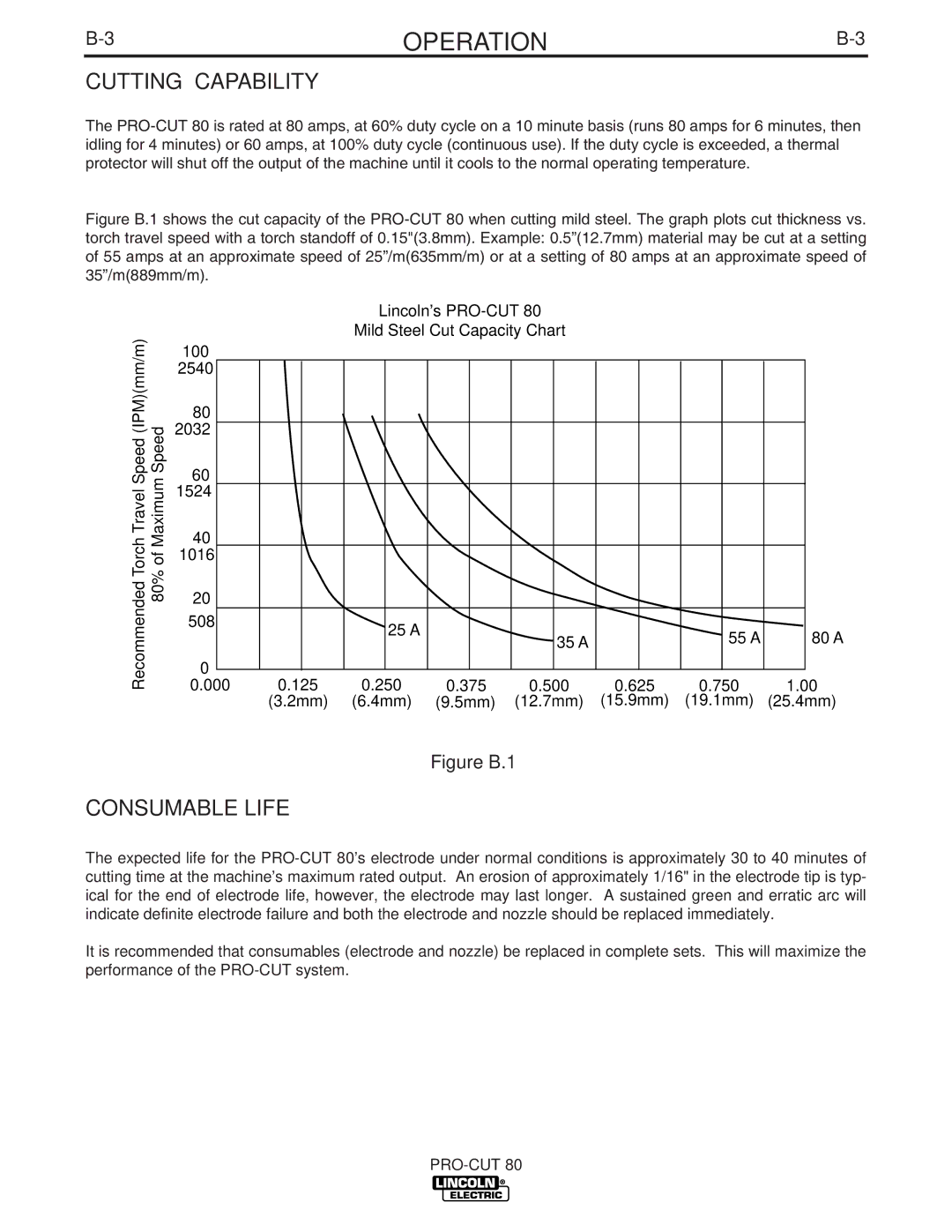

Figure B.1 shows the cut capacity of the PRO-CUT 80 when cutting mild steel. The graph plots cut thickness vs. torch travel speed with a torch standoff of 0.15"(3.8mm). Example: 0.5”(12.7mm) material may be cut at a setting of 55 amps at an approximate speed of 25”/m(635mm/m) or at a setting of 80 amps at an approximate speed of 35”/m(889mm/m).

Recommended Torch Travel Speed (IPM)(mm/m) | 80% of Maximum Speed |

100

2540

80

2032

60

1524

40

1016

20

508

0

0.000

Lincoln’s

Mild Steel Cut Capacity Chart

|

|

| 25 A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

| 35 A |

|

|

| 55 A |

| 80 A | |

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.125 | 0.250 | 0.375 | 0.500 | 0.625 | 0.750 | 1.00 | |||||||

(3.2mm) | (6.4mm) | (9.5mm) | (12.7mm) | (15.9mm) | (19.1mm) | (25.4mm) | |||||||

Figure B.1

CONSUMABLE LIFE

The expected life for the

It is recommended that consumables (electrode and nozzle) be replaced in complete sets. This will maximize the performance of the