OPERATION | ||

|

|

|

LIMITATIONS

Do not exceed the output current and duty cycle rating of machine. Do not use the

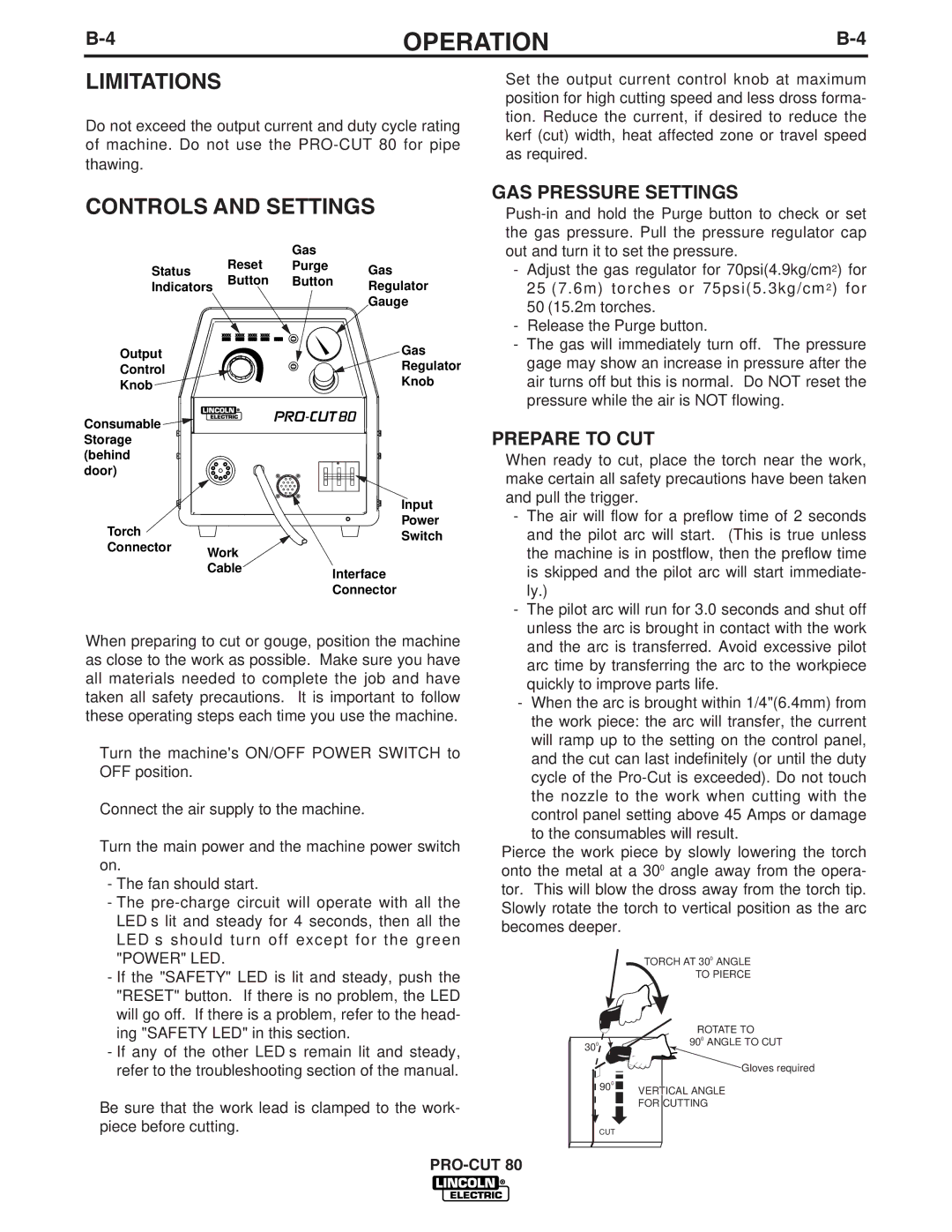

CONTROLS AND SETTINGS

|

|

| Reset | Gas |

|

| |

Status |

| Purge |

| Gas | |||

| Button | Button |

| ||||

Indicators |

|

| Regulator | ||||

|

|

|

|

| |||

|

|

|

|

|

|

| Gauge |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

•Set the output current control knob at maximum position for high cutting speed and less dross forma- tion. Reduce the current, if desired to reduce the kerf (cut) width, heat affected zone or travel speed as required.

GAS PRESSURE SETTINGS

• | |

the gas pressure. Pull the pressure regulator cap | |

out and turn it to set the pressure. | |

- | Adjust the gas regulator for 70psi(4.9kg/cm2) for |

| 25’(7.6m) torches or 75psi(5.3kg/cm2) for |

| 50’(15.2m torches. |

- | Release the Purge button. |

Output

Control

Knob

Consumable ![]() Storage (behind

Storage (behind ![]() door)

door)

XXXX XXXX XXXX XXXX

Gas

Regulator

Knob

- The gas will immediately turn off. The pressure |

gage may show an increase in pressure after the |

air turns off but this is normal. Do NOT reset the |

pressure while the air is NOT flowing. |

PREPARE TO CUT

• When ready to cut, place the torch near the work, |

make certain all safety precautions have been taken |

and pull the trigger. |

Torch Connector

Work Cable

Input

Power

Switch

Interface

Connector

- | The air will flow for a preflow time of 2 seconds |

| and the pilot arc will start. (This is true unless |

| the machine is in postflow, then the preflow time |

| is skipped and the pilot arc will start immediate- |

| ly.) |

- | The pilot arc will run for 3.0 seconds and shut off |

| unless the arc is brought in contact with the work |

When preparing to cut or gouge, position the machine as close to the work as possible. Make sure you have all materials needed to complete the job and have taken all safety precautions. It is important to follow these operating steps each time you use the machine.

•Turn the machine's ON/OFF POWER SWITCH to OFF position.

•Connect the air supply to the machine.

•Turn the main power and the machine power switch on.

-The fan should start.

-The

-If the "SAFETY" LED is lit and steady, push the "RESET" button. If there is no problem, the LED will go off. If there is a problem, refer to the head- ing "SAFETY LED" in this section.

-If any of the other LED’s remain lit and steady, refer to the troubleshooting section of the manual.

•Be sure that the work lead is clamped to the work- piece before cutting.

and the arc is transferred. Avoid excessive pilot |

arc time by transferring the arc to the workpiece |

quickly to improve parts life. |

- When the arc is brought within 1/4"(6.4mm) from |

the work piece: the arc will transfer, the current |

will ramp up to the setting on the control panel, |

and the cut can last indefinitely (or until the duty |

cycle of the |

the nozzle to the work when cutting with the |

control panel setting above 45 Amps or damage |

to the consumables will result. |

• Pierce the work piece by slowly lowering the torch |

onto the metal at a 300 angle away from the opera- |

tor. This will blow the dross away from the torch tip. |

Slowly rotate the torch to vertical position as the arc |

becomes deeper. |

| TORCH AT 300 ANGLE |

| TO PIERCE |

| ROTATE TO |

300 | 900 ANGLE TO CUT |

| Gloves required |

| 900 |

| VERTICAL ANGLE |

| FOR CUTTING |

| CUT |