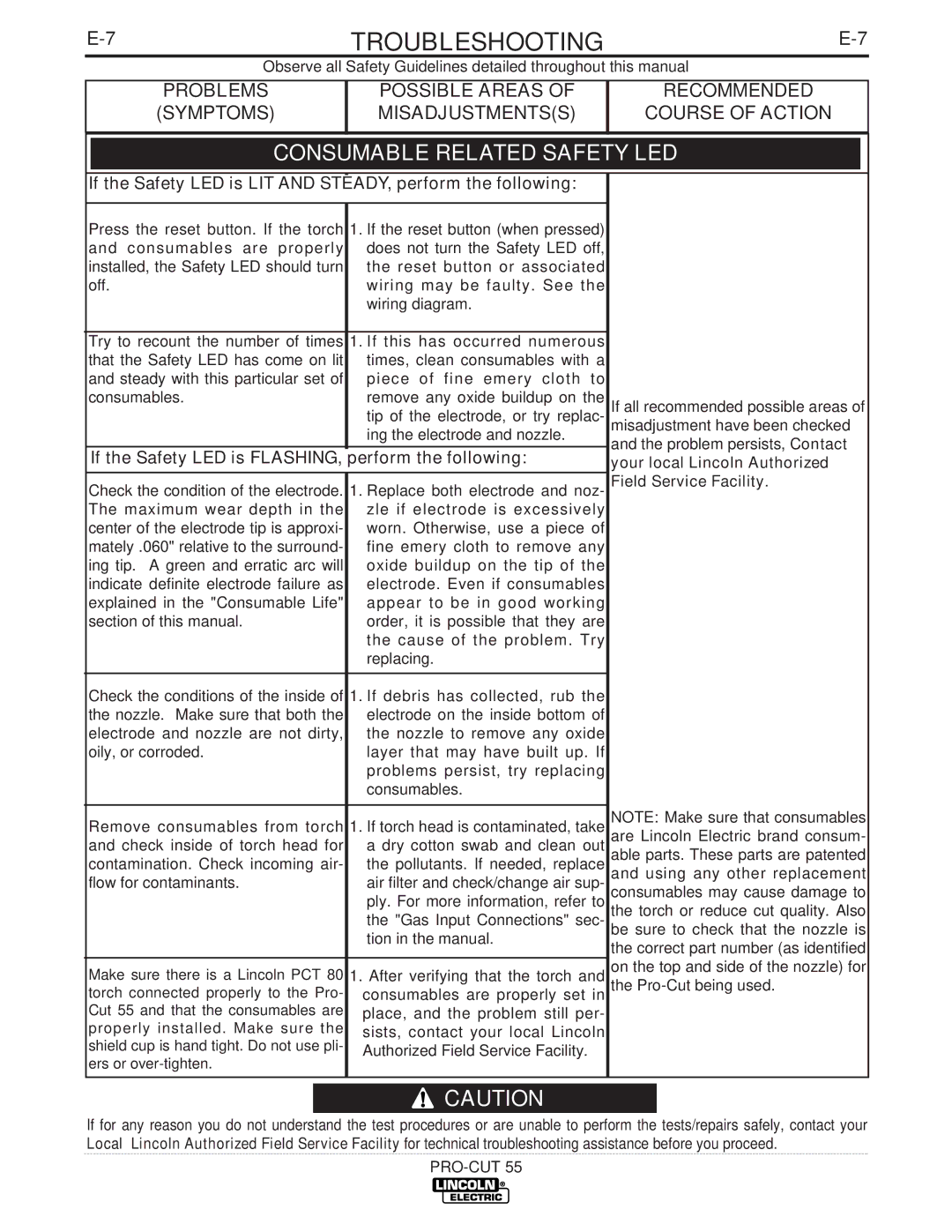

TROUBLESHOOTING | ||

|

|

|

| Observe all Safety Guidelines detailed throughout this manual |

|

|

|

|

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF MISADJUSTMENTS(S)

RECOMMENDED

COURSE OF ACTION

CONSUMABLE RELATED SAFETY LED

If the Safety LED is LIT AND STEADY, perform the following:

Press the reset button. If the torch | 1. | If the reset button (when pressed) |

| |

and consumables are properly |

| does not turn the Safety LED off, |

| |

installed, the Safety LED should turn |

| the reset button or associated |

| |

off. |

| wiring may be faulty. See the |

| |

|

| wiring diagram. |

| |

|

|

|

| |

Try to recount the number of times | 1. | If this has occurred numerous |

| |

that the Safety LED has come on lit |

| times, clean consumables with a |

| |

and steady with this particular set of |

| piece of fine emery cloth to |

| |

consumables. |

| remove any oxide buildup on the | If all recommended possible areas of | |

|

| tip of the electrode, or try replac- | misadjustment have been checked | |

|

| ing the electrode and nozzle. | and the problem persists, Contact | |

If the Safety LED is FLASHING, perform the following: | ||||

your local Lincoln Authorized | ||||

Check the condition of the electrode. | 1. | Replace both electrode and noz- | Field Service Facility. | |

The maximum wear depth in the |

| zle if electrode is excessively |

| |

center of the electrode tip is approxi- |

| worn. Otherwise, use a piece of |

| |

mately .060" relative to the surround- |

| fine emery cloth to remove any |

| |

ing tip. A green and erratic arc will |

| oxide buildup on the tip of the |

| |

indicate definite electrode failure as |

| electrode. Even if consumables |

| |

explained in the "Consumable Life" |

| appear to be in good working |

| |

section of this manual. |

| order, it is possible that they are |

| |

|

| the cause of the problem. Try |

| |

|

| replacing. |

| |

|

|

|

| |

Check the conditions of the inside of | 1. | If debris has collected, rub the |

| |

the nozzle. Make sure that both the |

| electrode on the inside bottom of |

| |

electrode and nozzle are not dirty, |

| the nozzle to remove any oxide |

| |

oily, or corroded. |

| layer that may have built up. If |

| |

|

| problems persist, try replacing |

| |

|

| consumables. |

| |

|

|

| NOTE: Make sure that consumables | |

Remove consumables from torch | 1. | If torch head is contaminated, take | ||

are Lincoln Electric brand consum- | ||||

and check inside of torch head for |

| a dry cotton swab and clean out | able parts. These parts are patented | |

contamination. Check incoming air- |

| the pollutants. If needed, replace | and using any other replacement | |

flow for contaminants. |

| air filter and check/change air sup- | consumables may cause damage to | |

|

| ply. For more information, refer to | the torch or reduce cut quality. Also | |

|

| the "Gas Input Connections" sec- | be sure to check that the nozzle is | |

|

| tion in the manual. | the correct part number (as identified | |

|

|

| ||

Make sure there is a Lincoln PCT 80 | 1. After verifying that the torch and | on the top and side of the nozzle) for | ||

torch connected properly to the Pro- |

| consumables are properly set in | the | |

Cut 55 and that the consumables are |

| place, and the problem still per- |

| |

properly installed. Make sure the |

| sists, contact your local Lincoln |

| |

shield cup is hand tight. Do not use pli- |

| Authorized Field Service Facility. |

| |

ers or |

|

|

| |

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.