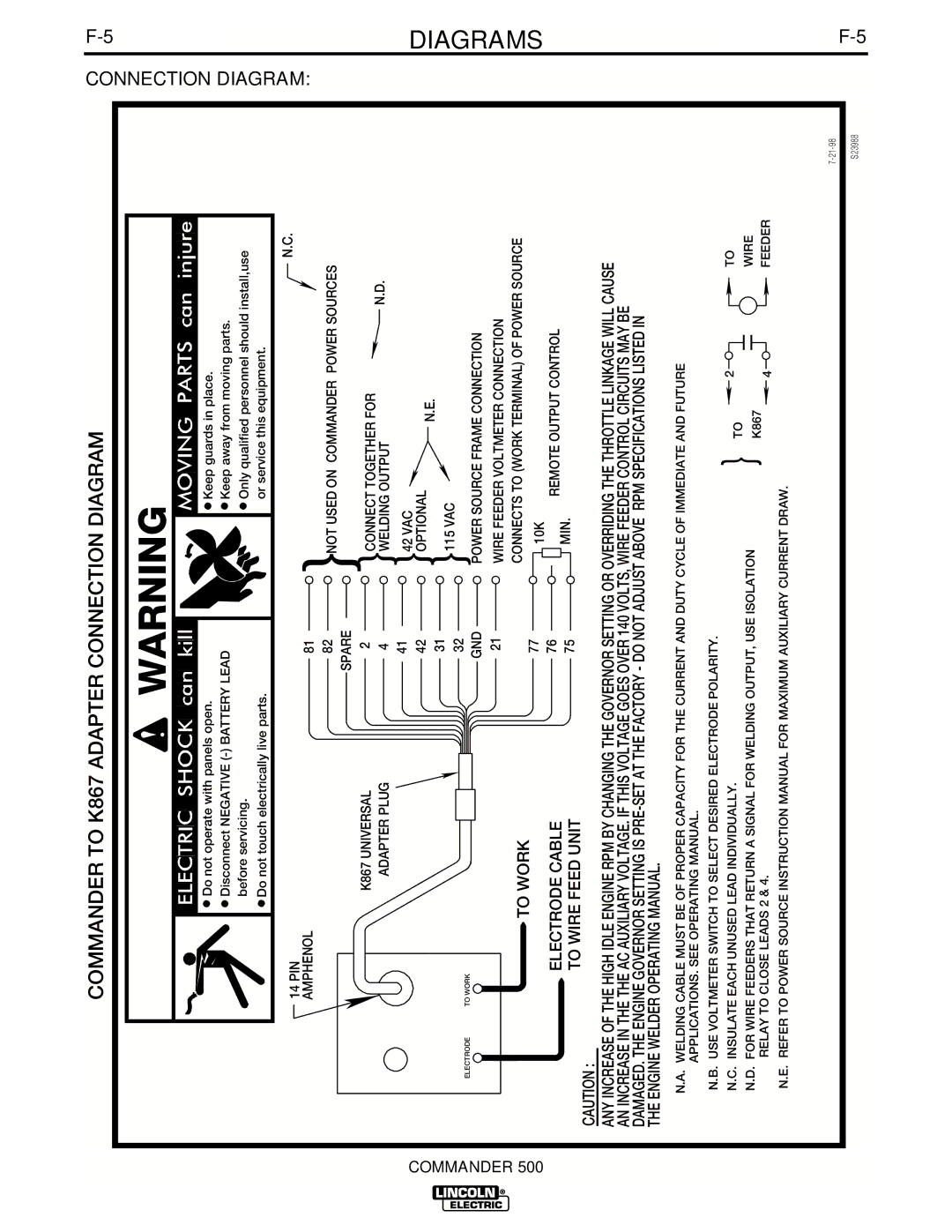

COMMANDER TO K867 ADAPTER CONNECTION DIAGRAM

![]() WARNING

WARNING

Do not operate with panels open. | Keep guards in place. |

Disconnect NEGATIVE | Keep away from moving parts. |

before servicing. | Only qualified personnel should install,use |

Do not touch electrically live parts. | or service this equipment. |

CONNECTION DIAGRAM:

COMMANDER 500

14PIN AMPHENOL

K867 UNIVERSAL

ADAPTER PLUG

ELECTRODE | TO WORK |

TO WORK |

ELECTRODE CABLE |

TO WIRE FEED UNIT

|

|

| N.C. |

81 | }NOT USED ON COMMANDER POWER SOURCES | ||

SPARE82 | |||

2 | CONNECT TOGETHER FOR | N.D. | |

| |||

4 | }WELDING OUTPUT |

| |

|

| ||

41 | 42 VAC |

|

|

|

|

| |

42 | }OPTIONAL | N.E. |

|

31 | }115 VAC |

| |

|

| ||

32 |

|

| |

GND | POWER SOURCE FRAME CONNECTION |

| |

21 | WIRE FEEDER VOLTMETER CONNECTION |

| |

| CONNECTS TO (WORK TERMINAL) OF POWER SOURCE | ||

77 | 10K |

|

|

76 |

|

| |

REMOTE OUTPUT CONTROL |

| ||

75 | MIN. |

|

|

|

|

| |

DIAGRAMS

CAUTION :

ANY INCREASE OF THE HIGH IDLE ENGINE RPM BY CHANGING THE GOVERNOR SETTING OR OVERRIDING THE THROTTLE LINKAGE WILL CAUSE AN INCREASE IN THE THE AC AUXILIARY VOLTAGE. IF THIS VOLTAGE GOES OVER 140 VOLTS, WIRE FEEDER CONTROL CIRCUITS MAY BE DAMAGED. THE ENGINE GOVERNOR SETTING IS

THE ENGINE WELDER OPERATING MANUAL.

N.A. WELDING CABLE MUST BE OF PROPER CAPACITY FOR THE CURRENT AND DUTY CYCLE OF IMMEDIATE AND FUTURE APPLICATIONS. SEE OPERATING MANUAL.

N.B. USE VOLTMETER SWITCH TO SELECT DESIRED ELECTRODE POLARITY. |

|

|

|

|

|

| |

N.C. INSULATE EACH UNUSED LEAD INDIVIDUALLY. | { |

|

|

| 2 | ||

|

| ||||||

N.D. FOR WIRE FEEDERS THAT RETURN A SIGNAL FOR WELDING OUTPUT, USE ISOLATION | TO | ||||||

| |||||||

| K867 | ||||||

RELAY TO CLOSE LEADS 2 & 4. |

| ||||||

|

|

| 4 | ||||

|

| ||||||

N.E. REFER TO POWER SOURCE INSTRUCTION MANUAL FOR MAXIMUM AUXILIARY CURRENT DRAW.

TO

WIRE FEEDER

S23988