| OPERATION |

| ||

|

|

|

|

|

WELDER CONTROLS (Items 9 through 14 )

9.OUTPUT  SELECTOR SWITCH & OUTPUT CONTROL

SELECTOR SWITCH & OUTPUT CONTROL

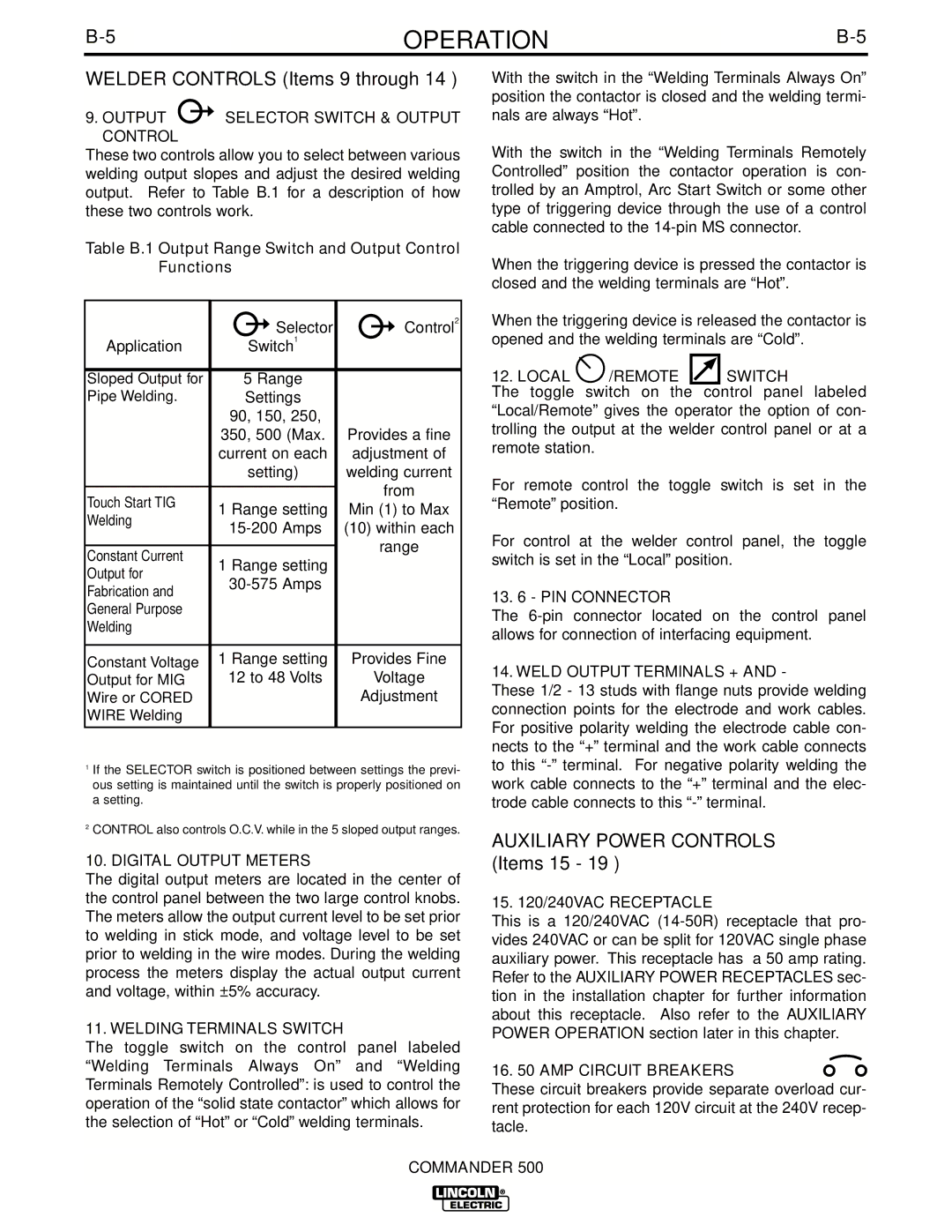

These two controls allow you to select between various welding output slopes and adjust the desired welding output. Refer to Table B.1 for a description of how these two controls work.

Table B.1 Output Range Switch and Output Control Functions

| Selector | Control2 | |

Application | Switch1 |

| |

|

|

| |

Sloped Output for | 5 Range |

| |

Pipe Welding. | Settings |

| |

| 90, 150, 250, |

| |

| 350, 500 (Max. | Provides a fine | |

| current on each | adjustment of | |

| setting) | welding current | |

|

| from | |

Touch Start TIG |

| ||

1 Range setting | Min (1) to Max | ||

Welding | |||

(10) within each | |||

| |||

|

| range | |

Constant Current | 1 Range setting | ||

| |||

Output for |

| ||

| |||

Fabrication and |

| ||

|

| ||

General Purpose |

|

| |

Welding |

|

| |

|

|

| |

Constant Voltage | 1 Range setting | Provides Fine | |

Output for MIG | 12 to 48 Volts | Voltage | |

Wire or CORED |

| Adjustment | |

WIRE Welding |

|

| |

|

|

|

1If the SELECTOR switch is positioned between settings the previ- ous setting is maintained until the switch is properly positioned on a setting.

2CONTROL also controls O.C.V. while in the 5 sloped output ranges.

10. DIGITAL OUTPUT METERS

The digital output meters are located in the center of the control panel between the two large control knobs. The meters allow the output current level to be set prior to welding in stick mode, and voltage level to be set prior to welding in the wire modes. During the welding process the meters display the actual output current and voltage, within ±5% accuracy.

11. WELDING TERMINALS SWITCH

The toggle switch on the control panel labeled “Welding Terminals Always On” and “Welding Terminals Remotely Controlled”: is used to control the operation of the “solid state contactor” which allows for the selection of “Hot” or “Cold” welding terminals.

With the switch in the “Welding Terminals Always On” position the contactor is closed and the welding termi- nals are always “Hot”.

With the switch in the “Welding Terminals Remotely Controlled” position the contactor operation is con- trolled by an Amptrol, Arc Start Switch or some other type of triggering device through the use of a control cable connected to the

When the triggering device is pressed the contactor is closed and the welding terminals are “Hot”.

When the triggering device is released the contactor is opened and the welding terminals are “Cold”.

12. LOCAL | /REMOTE |

| SWITCH |

The toggle | switch on the | control panel labeled | |

“Local/Remote” gives the operator the option of con- trolling the output at the welder control panel or at a remote station.

For remote control the toggle switch is set in the “Remote” position.

For control at the welder control panel, the toggle switch is set in the “Local” position.

13. 6 - PIN CONNECTOR

The

14. WELD OUTPUT TERMINALS + AND -

These 1/2 - 13 studs with flange nuts provide welding connection points for the electrode and work cables. For positive polarity welding the electrode cable con- nects to the “+” terminal and the work cable connects to this

AUXILIARY POWER CONTROLS

(Items 15 - 19 )

15. 120/240VAC RECEPTACLE

This is a 120/240VAC

16. 50 AMP CIRCUIT BREAKERS ![]()

![]() These circuit breakers provide separate overload cur- rent protection for each 120V circuit at the 240V recep- tacle.

These circuit breakers provide separate overload cur- rent protection for each 120V circuit at the 240V recep- tacle.

COMMANDER 500