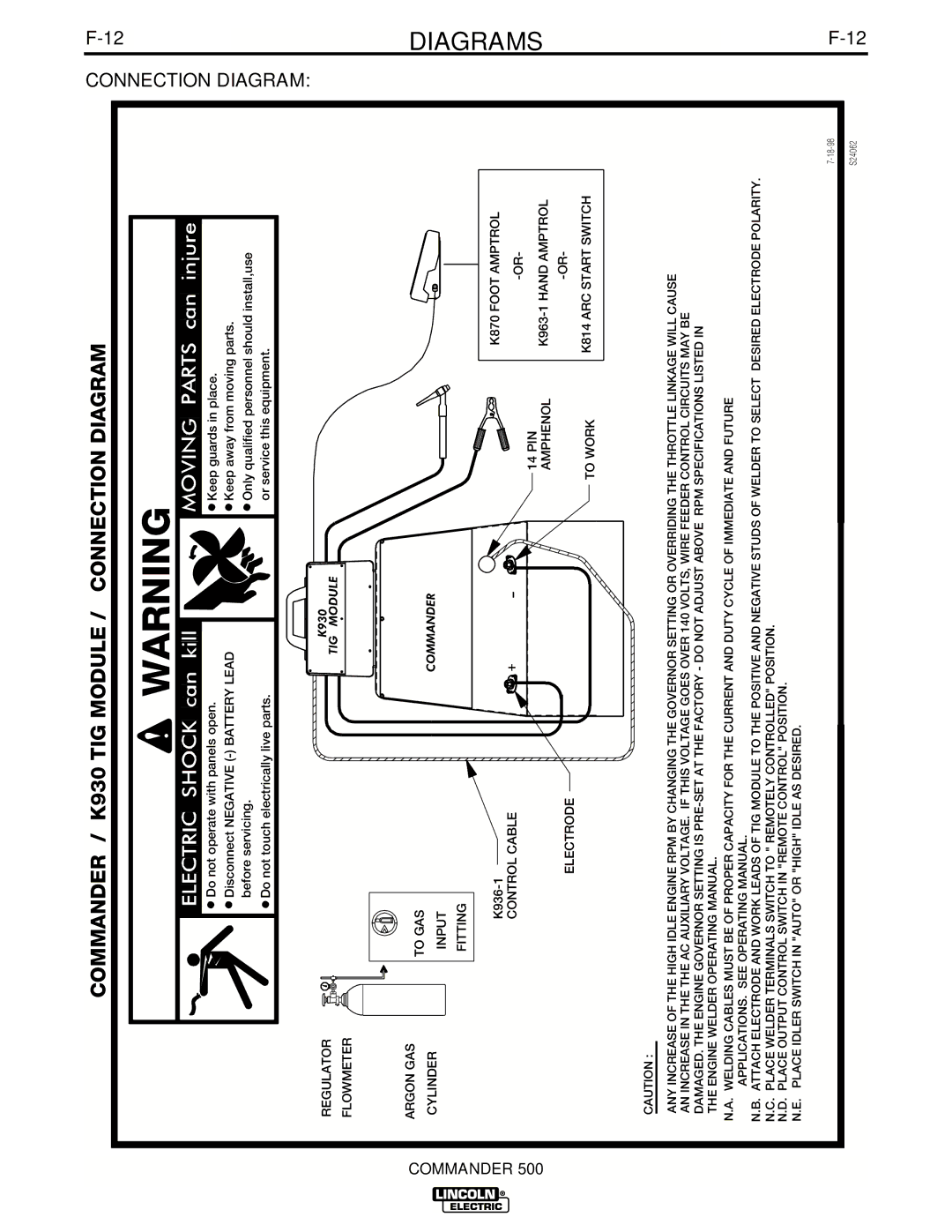

COMMANDER / K930 TIG MODULE / CONNECTION DIAGRAM

![]() WARNING

WARNING

Do not operate with panels open. | Keep guards in place. |

Disconnect NEGATIVE | Keep away from moving parts. |

before servicing. | Only qualified personnel should install,use |

Do not touch electrically live parts. | or service this equipment. |

CONNECTION DIAGRAM:

COMMANDER 500

REGULATOR FLOWMETER

ARGON GAS CYLINDER

TO GAS

INPUT

FITTING

CONTROL CABLE

ELECTRODE

14PIN AMPHENOL

TO WORK

K870 FOOT AMPTROL

K814 ARC START SWITCH

DIAGRAMS

CAUTION :

ANY INCREASE OF THE HIGH IDLE ENGINE RPM BY CHANGING THE GOVERNOR SETTING OR OVERRIDING THE THROTTLE LINKAGE WILL CAUSE AN INCREASE IN THE THE AC AUXILIARY VOLTAGE. IF THIS VOLTAGE GOES OVER 140 VOLTS, WIRE FEEDER CONTROL CIRCUITS MAY BE DAMAGED. THE ENGINE GOVERNOR SETTING IS

THE ENGINE WELDER OPERATING MANUAL.

N.A. WELDING CABLES MUST BE OF PROPER CAPACITY FOR THE CURRENT AND DUTY CYCLE OF IMMEDIATE AND FUTURE APPLICATIONS. SEE OPERATING MANUAL.

N.B. ATTACH ELECTRODE AND WORK LEADS OF TIG MODULE TO THE POSITIVE AND NEGATIVE STUDS OF WELDER TO SELECT DESIRED ELECTRODE POLARITY. N.C. PLACE WELDER TERMINALS SWITCH TO " REMOTELY CONTROLLED" POSITION.

N.D. PLACE OUTPUT CONTROL SWITCH IN "REMOTE CONTROL" POSITION. N.E. PLACE IDLER SWITCH IN "AUTO" OR "HIGH" IDLE AS DESIRED.

S24062