OPERATION | ||

|

|

|

WIRE FEED (CONSTANT VOLTAGE) WELDING

Connect a wire feeder to the Commander 300 and set welder controls according to the instructions listed earlier in this section.

The Commander 300 in the ”WIRE WELDING” position, permits it to be used with a broad range of flux cored wire (Innershield and Outershield) electrodes and solid wires for MIG welding (gas metal arc welding). Welding can be finely tuned using the “ARC CONTROL”.

Electrodes suitable for use are:

Electrodes suitable for use are:

Electrodes suitable for wires for MIG welding are: .035 (0.9 mm), .045 (1.1 mm) and .052 (1.3 mm),

.035 (0.9 mm) and .045 (1.1 mm) Blue Max MIG 308 LS.

For any electrodes, including the above recommenda- tions, the procedures should be kept within the rating of the machine. For additional electrode information, see Lincoln publications

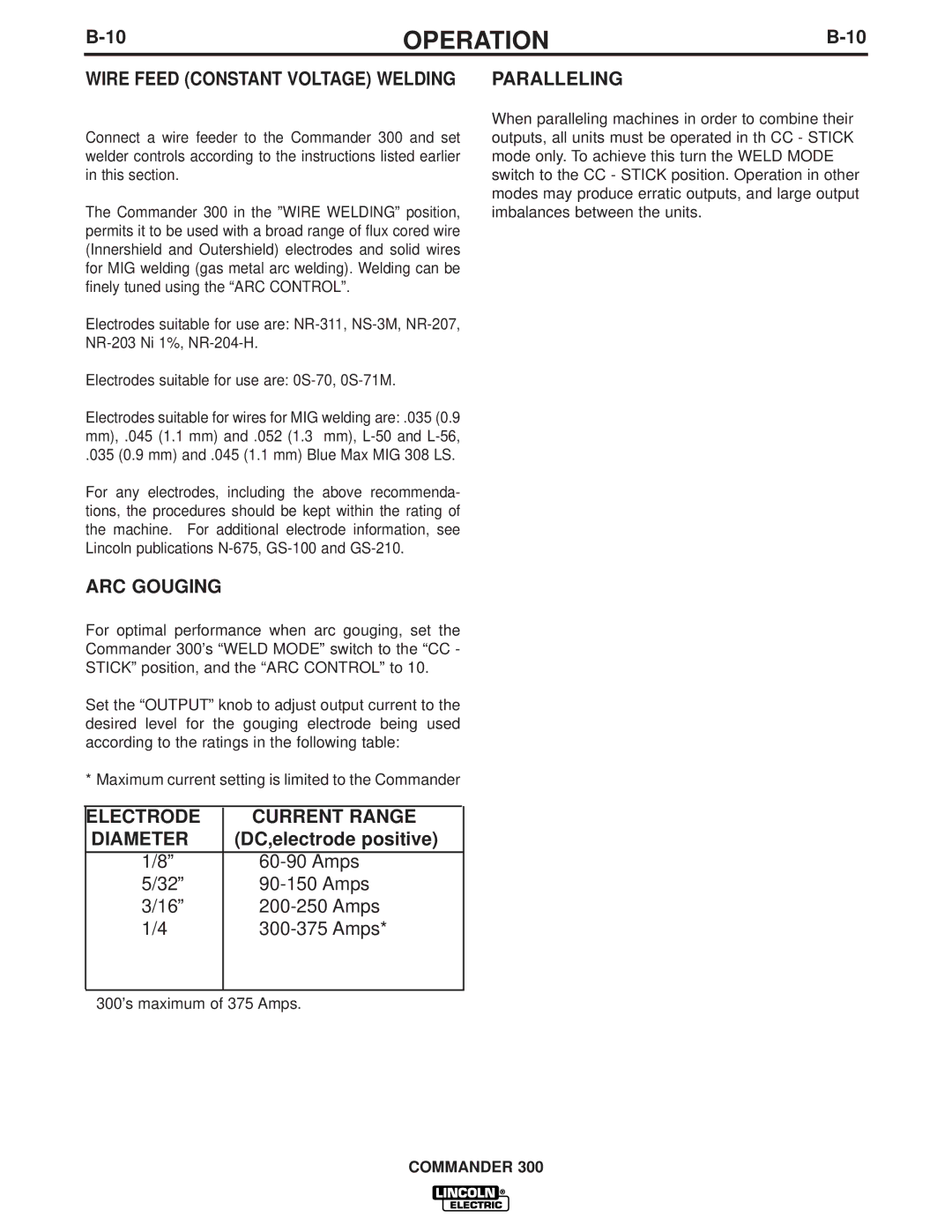

ARC GOUGING

For optimal performance when arc gouging, set the Commander 300’s “WELD MODE” switch to the “CC - STICK” position, and the “ARC CONTROL” to 10.

Set the “OUTPUT” knob to adjust output current to the desired level for the gouging electrode being used according to the ratings in the following table:

* Maximum current setting is limited to the Commander

ELECTRODE | CURRENT RANGE |

DIAMETER | (DC,electrode positive) |

|

|

1/8” | |

5/32” | |

3/16” | |

1/4 | |

|

|

PARALLELING

When paralleling machines in order to combine their outputs, all units must be operated in th CC - STICK mode only. To achieve this turn the WELD MODE switch to the CC - STICK position. Operation in other modes may produce erratic outputs, and large output imbalances between the units.

300’s maximum of 375 Amps.

COMMANDER 300