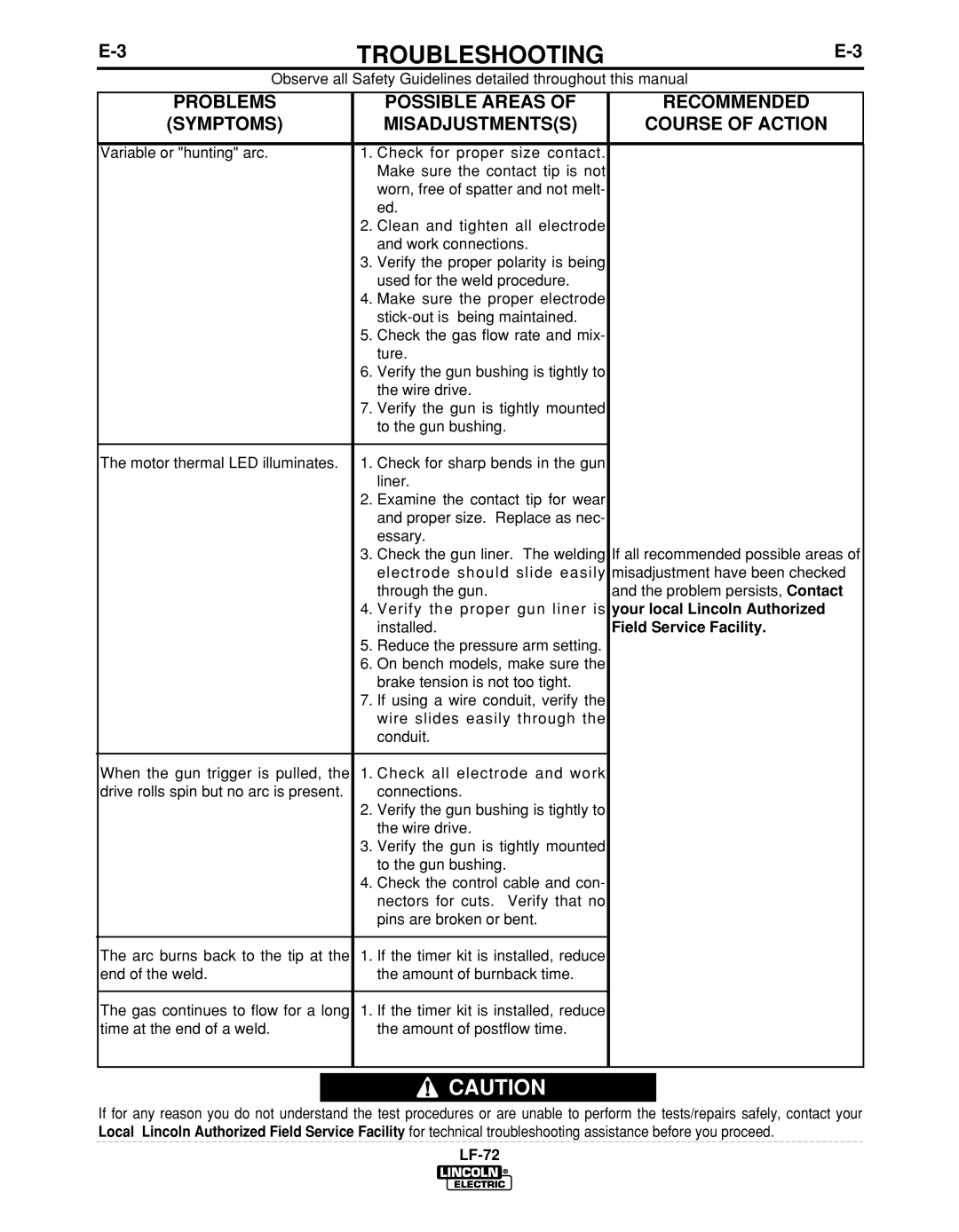

TROUBLESHOOTING | ||

|

|

|

| Observe all Safety Guidelines detailed throughout this manual |

|

|

|

|

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF MISADJUSTMENTS(S)

RECOMMENDED

COURSE OF ACTION

Variable or "hunting" arc. | 1. Check for proper size contact. | |

|

| Make sure the contact tip is not |

|

| worn, free of spatter and not melt- |

|

| ed. |

| 2. | Clean and tighten all electrode |

|

| and work connections. |

| 3. | Verify the proper polarity is being |

|

| used for the weld procedure. |

| 4. | Make sure the proper electrode |

|

| |

| 5. | Check the gas flow rate and mix- |

|

| ture. |

| 6. | Verify the gun bushing is tightly to |

|

| the wire drive. |

| 7. | Verify the gun is tightly mounted |

|

| to the gun bushing. |

The motor thermal LED illuminates. 1. Check for sharp bends in the gun liner.

2.Examine the contact tip for wear and proper size. Replace as nec- essary.

3.Check the gun liner. The welding If all recommended possible areas of electrode should slide easily misadjustment have been checked

through the gun. | and the problem persists, Contact |

4.Verify the proper gun liner is your local Lincoln Authorized

installed. | Field Service Facility. |

5.Reduce the pressure arm setting.

6.On bench models, make sure the brake tension is not too tight.

7.If using a wire conduit, verify the wire slides easily through the conduit.

| When the gun trigger is pulled, the | 1. | Check all electrode and work |

|

| drive rolls spin but no arc is present. |

| connections. |

|

|

| 2. | Verify the gun bushing is tightly to |

|

|

|

| the wire drive. |

|

|

| 3. | Verify the gun is tightly mounted |

|

|

|

| to the gun bushing. |

|

|

| 4. | Check the control cable and con- |

|

|

|

| nectors for cuts. Verify that no |

|

|

|

| pins are broken or bent. |

|

|

|

|

|

|

| The arc burns back to the tip at the | 1. | If the timer kit is installed, reduce |

|

| end of the weld. |

| the amount of burnback time. |

|

|

|

|

|

|

| The gas continues to flow for a long | 1. | If the timer kit is installed, reduce |

|

| time at the end of a weld. |

| the amount of postflow time. |

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.