SVM152-A specifications

The Lincoln Electric SVM152-A is a cutting-edge semi-automatic wire-feed welding machine designed for professionals seeking high performance and efficiency in their welding tasks. This versatile welding system is known for its robust engineering, advanced technology, and user-friendly features, making it a preferred choice for various applications in metal fabrication, automotive repair, and construction.One of the standout features of the SVM152-A is its impressive versatility. It can accommodate a wide range of welding processes, including MIG, MAG, and FCAW. This flexibility allows users to switch between different welding techniques with ease, providing the adaptability needed for diverse project requirements. Additionally, the machine supports various wire diameters, catering to different welding applications and materials.

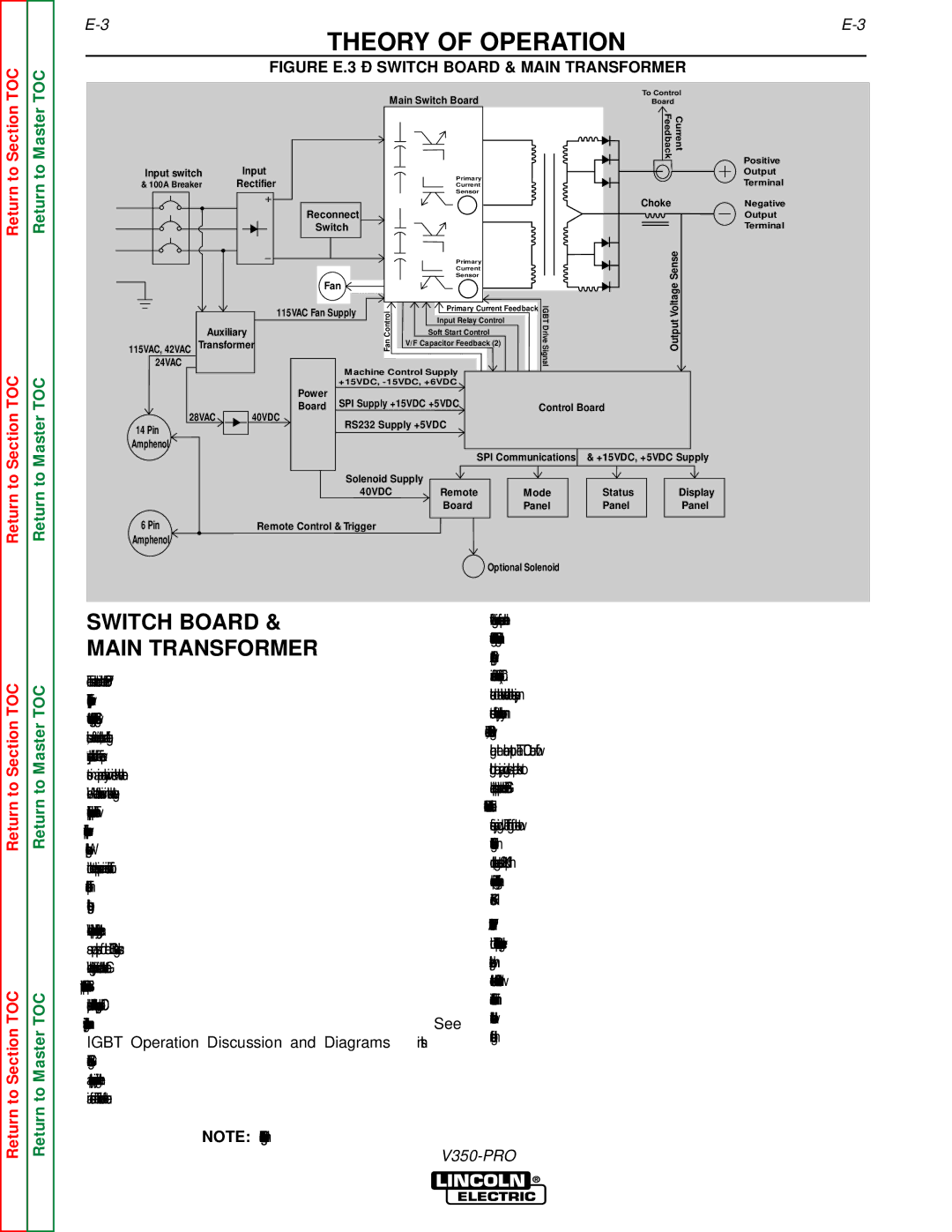

The SVM152-A boasts advanced inverter technology, which enhances its performance by increasing efficiency and reducing power consumption. This technology not only leads to lower operational costs but also provides a stable arc and improved weld quality. The inverter design enables the machine to maintain a consistent output, even in challenging conditions, ensuring a smooth welding experience.

Another key characteristic of the Lincoln Electric SVM152-A is its user-friendly interface. The machine features intuitive controls, making it accessible for both seasoned welders and those new to the craft. The digital display provides clear readings of key parameters, such as voltage and wire feed speed, allowing operators to make quick adjustments for optimal weld quality.

The construction of the SVM152-A is designed for durability and reliability. Made from high-quality materials, it can withstand the rigors of demanding work environments. The machine is also equipped with advanced cooling systems to prevent overheating during prolonged use, ensuring a longer lifespan and consistent performance.

Safety is a top priority in the design of the SVM152-A. The machine comes with built-in safety features, including thermal overload protection and circuit breakers, which help protect the equipment and the operator from potential hazards.

In summary, the Lincoln Electric SVM152-A combines versatility, advanced inverter technology, user-friendly controls, robust construction, and safety features, making it an excellent choice for professionals in various industries. Whether tackling intricate welding projects or high-volume production work, the SVM152-A delivers the performance and reliability that modern welders demand.