BOILER TARGET DURING SET POINT

The boiler target temperature during a set point demand is increased to at least the Set Point setting. This temperature is maintained as long as the control has a set point demand.

SET POINT MODE

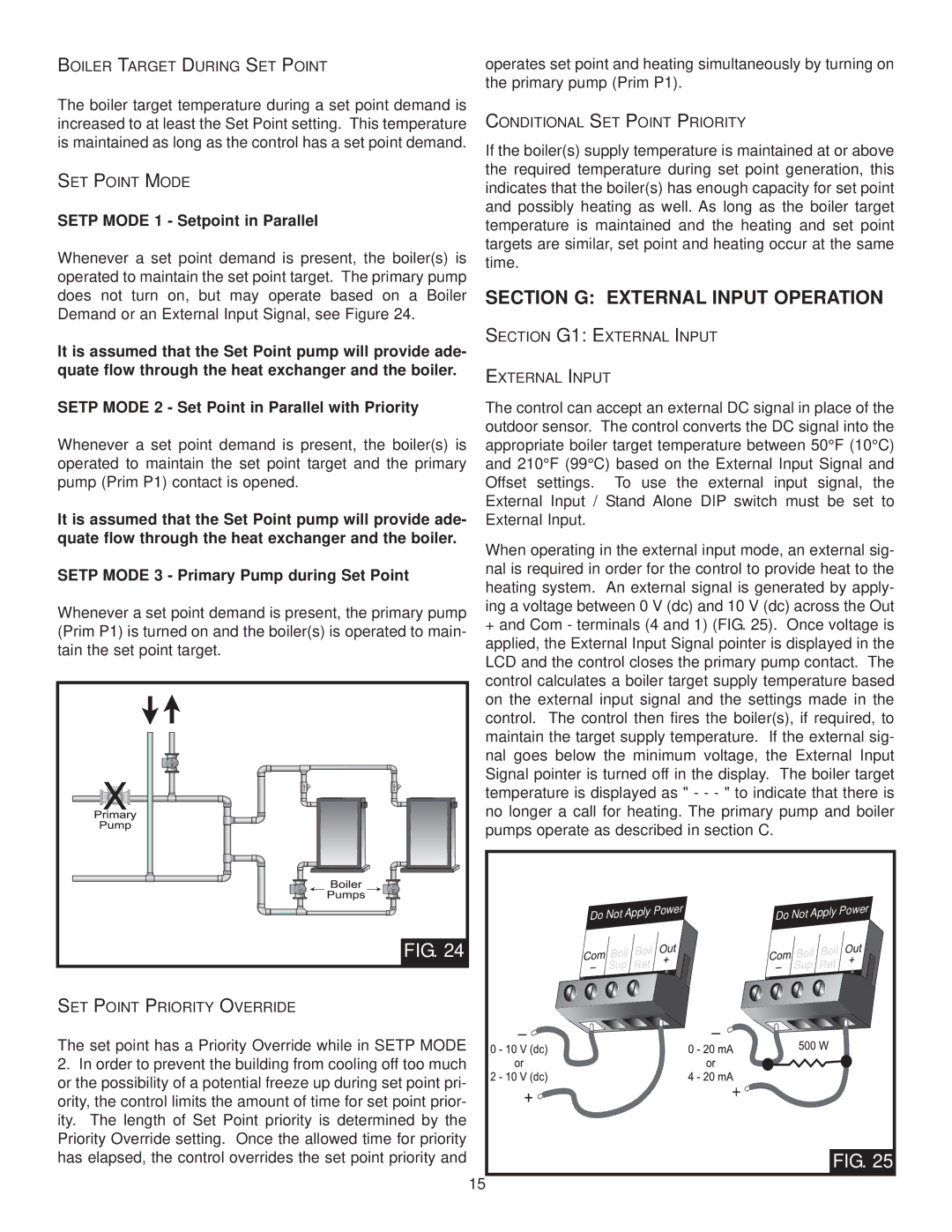

SETP MODE 1 - Setpoint in Parallel

Whenever a set point demand is present, the boiler(s) is operated to maintain the set point target. The primary pump does not turn on, but may operate based on a Boiler Demand or an External Input Signal, see Figure 24.

It is assumed that the Set Point pump will provide ade- quate flow through the heat exchanger and the boiler.

SETP MODE 2 - Set Point in Parallel with Priority

Whenever a set point demand is present, the boiler(s) is operated to maintain the set point target and the primary pump (Prim P1) contact is opened.

It is assumed that the Set Point pump will provide ade- quate flow through the heat exchanger and the boiler.

SETP MODE 3 - Primary Pump during Set Point

Whenever a set point demand is present, the primary pump (Prim P1) is turned on and the boiler(s) is operated to main- tain the set point target.

FIG. 24 |

SET POINT PRIORITY OVERRIDE

The set point has a Priority Override while in SETP MODE

2.In order to prevent the building from cooling off too much or the possibility of a potential freeze up during set point pri- ority, the control limits the amount of time for set point prior- ity. The length of Set Point priority is determined by the Priority Override setting. Once the allowed time for priority has elapsed, the control overrides the set point priority and

operates set point and heating simultaneously by turning on the primary pump (Prim P1).

CONDITIONAL SET POINT PRIORITY

If the boiler(s) supply temperature is maintained at or above the required temperature during set point generation, this indicates that the boiler(s) has enough capacity for set point and possibly heating as well. As long as the boiler target temperature is maintained and the heating and set point targets are similar, set point and heating occur at the same time.

SECTION G: EXTERNAL INPUT OPERATION

SECTION G1: EXTERNAL INPUT

EXTERNAL INPUT

The control can accept an external DC signal in place of the outdoor sensor. The control converts the DC signal into the appropriate boiler target temperature between 50°F (10°C) and 210°F (99°C) based on the External Input Signal and Offset settings. To use the external input signal, the External Input / Stand Alone DIP switch must be set to External Input.

When operating in the external input mode, an external sig- nal is required in order for the control to provide heat to the heating system. An external signal is generated by apply- ing a voltage between 0 V (dc) and 10 V (dc) across the Out

+and Com - terminals (4 and 1) (FIG. 25). Once voltage is applied, the External Input Signal pointer is displayed in the LCD and the control closes the primary pump contact. The control calculates a boiler target supply temperature based on the external input signal and the settings made in the control. The control then fires the boiler(s), if required, to maintain the target supply temperature. If the external sig- nal goes below the minimum voltage, the External Input Signal pointer is turned off in the display. The boiler target temperature is displayed as " - - - " to indicate that there is no longer a call for heating. The primary pump and boiler pumps operate as described in section C.

Do Not Apply | Power | Do Not Apply | Power |

|

| ||

– |

| – |

|

|

| + |

|

FIG. 25

15