P 2/ 16

Repair

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

[1] NECESSARY REPAIRING TOOLS

Code No. | Description | Use for |

1R003 | Retaining ring S pliers ST2N | removing / mounting Retaining ring |

1R031 | Bearing setting pipe | holding Bearing box when removing Helical gear 24 |

1R208 | 90 degree set square | adjusting the angle of Saw blade to 90 Degrees |

1R212 | Tip for Retaining ring pliers | attachment to 1R003 |

1R263 | Bearing extractor | removing Blade cover |

1R269 | Bearing extractor | removing Ball bearings |

1R291 | Retaining ring S & R pliers | removing Retaining ring |

1R361 | Bearing retainer tightening tool | removing / Mounting Bearing retainer |

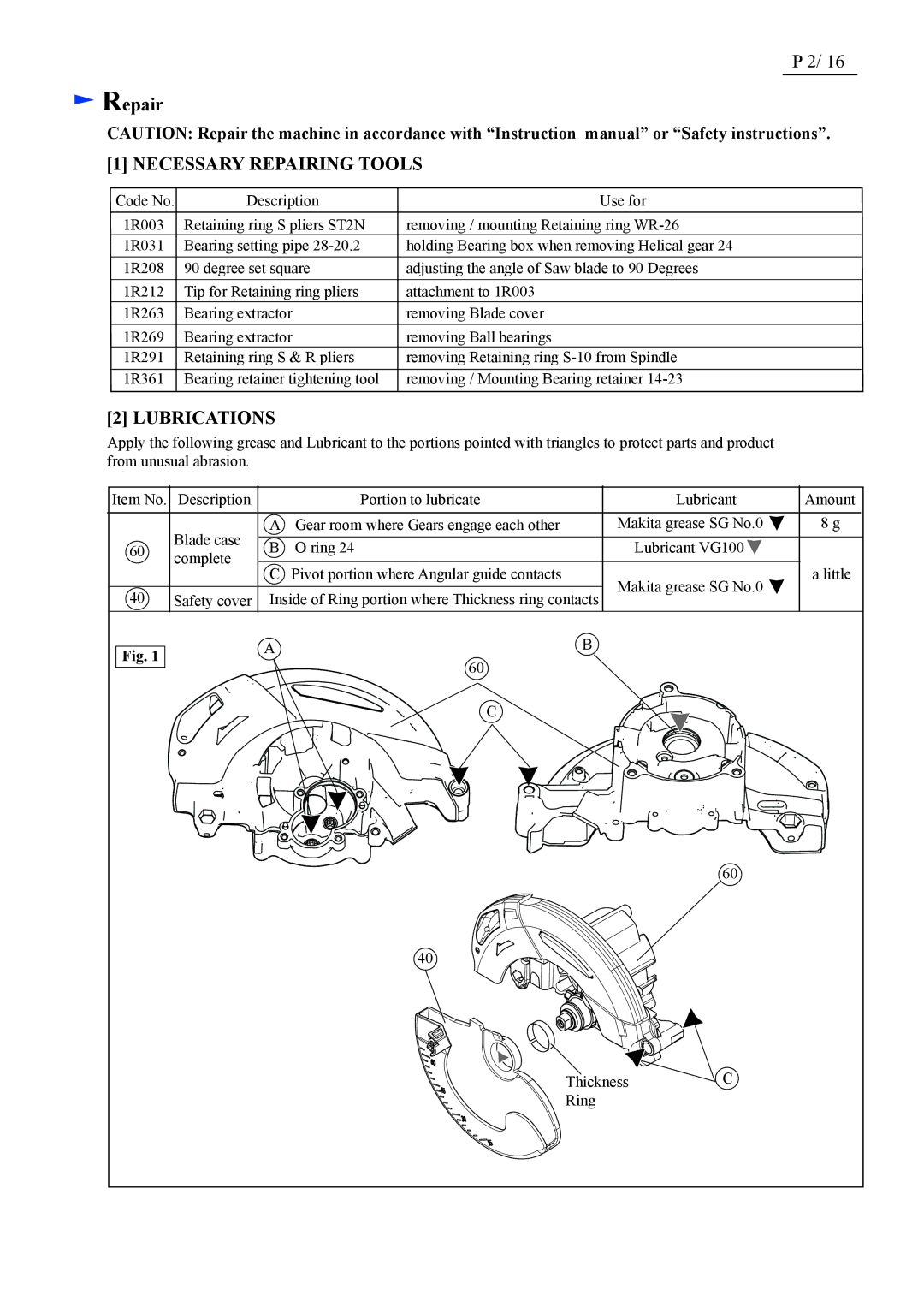

[2] LUBRICATIONS

Apply the following grease and Lubricant to the portions pointed with triangles to protect parts and product from unusual abrasion.

Item No. | Description |

| Portion to lubricate |

|

| Lubricant | Amount |

| Blade case | A | Gear room where Gears engage each other |

| Makita grease SG No.0 | 8 g | |

60 | B | O ring 24 |

|

| Lubricant VG100 |

| |

complete |

|

|

| ||||

| C Pivot portion where Angular guide contacts |

|

|

| a little | ||

|

|

| Makita grease SG No.0 | ||||

40 | Safety cover | Inside of Ring portion where Thickness ring contacts |

| ||||

|

|

| |||||

Fig. 1 |

| A | 60 | B |

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

| |

|

|

| C |

|

|

|

|

|

|

|

|

|

| 60 |

|

|

|

| 40 |

|

|

|

|

|

|

|

| Thickness | C |

| |

|

|

|

| Ring |

|

|

|