P 8/ 16

Repair

Repair

[3]DISASSEMBLY/ASSEMBLY

[3]-5. LED and Motor Section

DISASSEMBLING

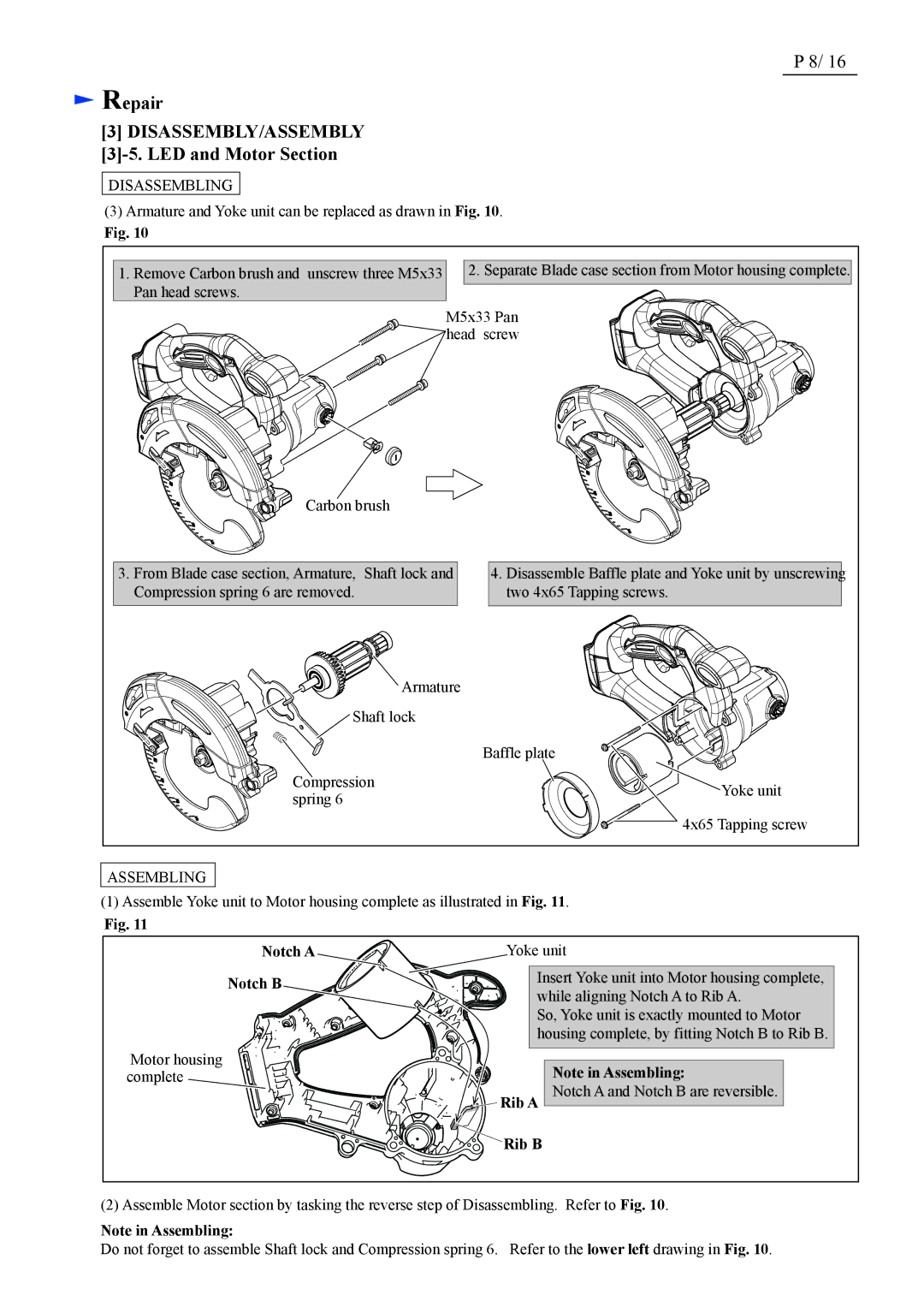

(3)Armature and Yoke unit can be replaced as drawn in Fig. 10.

Fig. 10

1.Remove Carbon brush and unscrew three M5x33 Pan head screws.

2. Separate Blade case section from Motor housing complete.

M5x33 Pan

![]()

![]()

![]()

![]()

![]() head screw

head screw

Carbon brush

3.From Blade case section, Armature, Shaft lock and Compression spring 6 are removed.

4.Disassemble Baffle plate and Yoke unit by unscrewing two 4x65 Tapping screws.

Armature |

| |

Shaft lock |

| |

| Baffle plate | |

Compression | Yoke unit | |

spring 6 | ||

| ||

| 4x65 Tapping screw |

ASSEMBLING

(1)Assemble Yoke unit to Motor housing complete as illustrated in Fig. 11.

Fig. 11

Notch A | Yoke unit | |

Notch B | Insert Yoke unit into Motor housing complete, | |

while aligning Notch A to Rib A. | ||

| ||

| So, Yoke unit is exactly mounted to Motor | |

| housing complete, by fitting Notch B to Rib B. | |

Motor housing | Note in Assembling: | |

complete | ||

| Rib A Notch A and Notch B are reversible. | |

| Rib B |

(2) Assemble Motor section by tasking the reverse step of Disassembling. Refer to Fig. 10.

Note in Assembling:

Do not forget to assemble Shaft lock and Compression spring 6. Refer to the lower left drawing in Fig. 10.