P 19/ 22

Repair

Repair

[4]DISASSEMBLY/ASSEMBLY [4]-13. Engine block (cont.)

DISASSEMBLING

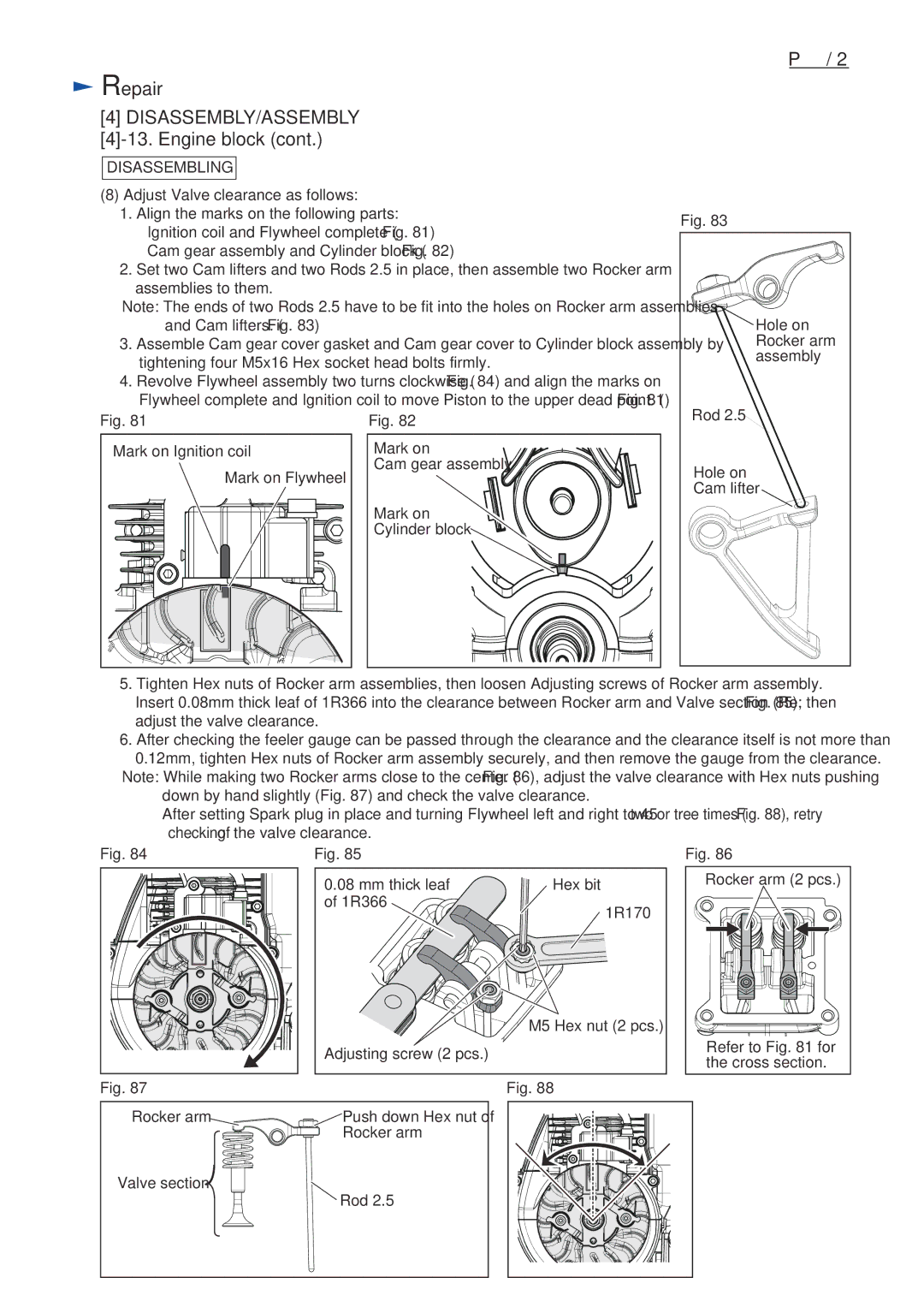

(8)Adjust Valve clearance as follows:

1.Align the marks on the following parts:

•Ignition coil and Flywheel complete (Fig. 81)

•Cam gear assembly and Cylinder block (Fig. 82)

2.Set two Cam lifters and two Rods 2.5 in place, then assemble two Rocker arm assemblies to them.

Note: The ends of two Rods 2.5 have to be fit into the holes on Rocker arm assemblies and Cam lifters. (Fig. 83)

3.Assemble Cam gear cover gasket and Cam gear cover to Cylinder block assembly by tightening four M5x16 Hex socket head bolts firmly.

4.Revolve Flywheel assembly two turns clockwise (Fig. 84) and align the marks on Flywheel complete and Ignition coil to move Piston to the upper dead point. (Fig. 81)

Fig. 81 | Fig. 82 |

Fig. 83

Hole on |

Rocker arm |

assembly |

Rod 2.5 |

Mark on Ignition coil |

Mark on Flywheel |

Mark on

Cam gear assembly

Mark on

Cylinder block

Hole on |

Cam lifter |

5.Tighten Hex nuts of Rocker arm assemblies, then loosen Adjusting screws of Rocker arm assembly.

Insert 0.08mm thick leaf of 1R366 into the clearance between Rocker arm and Valve section (Re: Fig. 85), then adjust the valve clearance.

6.After checking the feeler gauge can be passed through the clearance and the clearance itself is not more than 0.12mm, tighten Hex nuts of Rocker arm assembly securely, and then remove the gauge from the clearance.

Note: While making two Rocker arms close to the center (Fig. 86), adjust the valve clearance with Hex nuts pushing down by hand slightly (Fig. 87) and check the valve clearance.

After setting Spark plug in place and turning Flywheel left and right to 45° two or tree times (Fig. 88), retry checking of the valve clearance.

Fig. 84 | Fig. 85 |

|

| 0.08 mm thick leaf | Hex bit |

| of 1R366 | 1R170 |

|

|

M5 Hex nut (2 pcs.)

| Adjusting screw (2 pcs.) |

Fig. 87 | Fig. 88 |

Rocker arm | Push down Hex nut of |

| Rocker arm |

Valve section | Rod 2.5 |

|

Fig. 86

Rocker arm (2 pcs.)

Refer to Fig. 81 for the cross section.