P 14/22

Repair

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-6. Needle bearing complete and Oil seal 25

DISASSEMBLING

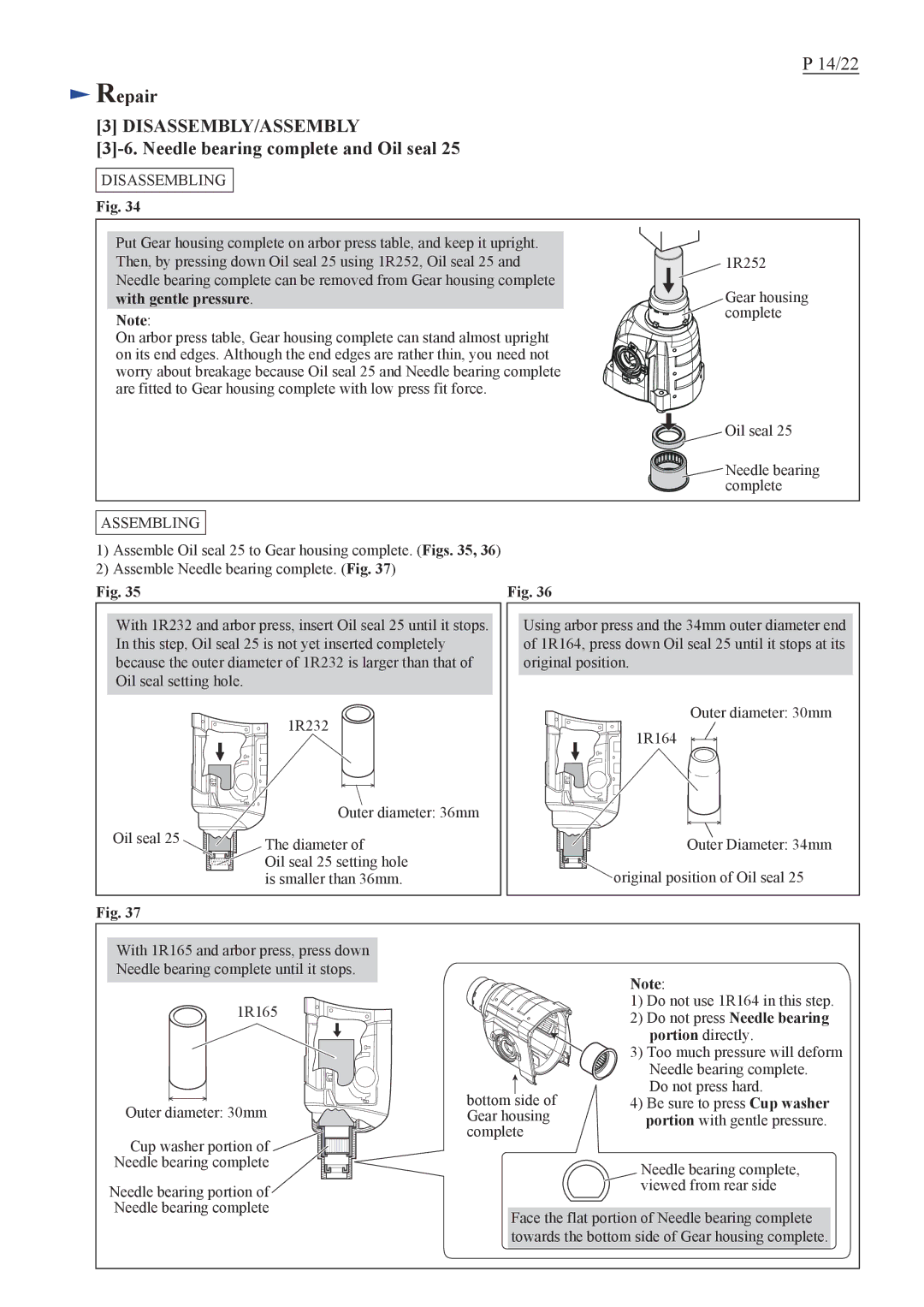

Fig. 34

Put Gear housing complete on arbor press table, and keep it upright.

Then, by pressing down Oil seal 25 using 1R252, Oil seal 25 and | 1R252 |

Needle bearing complete can be removed from Gear housing complete | Gear housing |

with gentle pressure. | |

Note: | complete |

On arbor press table, Gear housing complete can stand almost upright |

|

on its end edges. Although the end edges are rather thin, you need not |

|

worry about breakage because Oil seal 25 and Needle bearing complete |

|

are fitted to Gear housing complete with low press fit force. |

|

| Oil seal 25 |

| Needle bearing |

| complete |

ASSEMBLING

1)Assemble Oil seal 25 to Gear housing complete. (Figs. 35, 36)

2)Assemble Needle bearing complete. (Fig. 37)

Fig. 35 | Fig. 36 |

With 1R232 and arbor press, insert Oil seal 25 until it stops. In this step, Oil seal 25 is not yet inserted completely because the outer diameter of 1R232 is larger than that of

Using arbor press and the 34mm outer diameter end of 1R164, press down Oil seal 25 until it stops at its original position.

Oil seal setting hole.

Oil seal 25

1R232

Outer diameter: 36mm

The diameter of

Oil seal 25 setting hole is smaller than 36mm.

Outer diameter: 30mm

1R164

Outer Diameter: 34mm

![]() original position of Oil seal 25

original position of Oil seal 25

Fig. 37

With 1R165 and arbor press, press down Needle bearing complete until it stops.

1R165

Outer diameter: 30mm

Cup washer portion of ![]()

![]()

![]() Needle bearing complete

Needle bearing complete ![]()

![]()

![]()

![]()

![]()

![]()

![]()

Needle bearing portion of Needle bearing complete

bottom side of Gear housing complete

Note:

1)Do not use 1R164 in this step.

2)Do not press Needle bearing portion directly.

3)Too much pressure will deform Needle bearing complete.

Do not press hard.

4)Be sure to press Cup washer portion with gentle pressure.

Needle bearing complete, viewed from rear side

Face the flat portion of Needle bearing complete towards the bottom side of Gear housing complete.