P 4/16

Repair

Repair

[3]DISASSEMBLY/ASSEMBLY

[3]-1. Base

ASSEMBLING

Base can be mounted to the machine by taking the reverse steps of Disassembling.

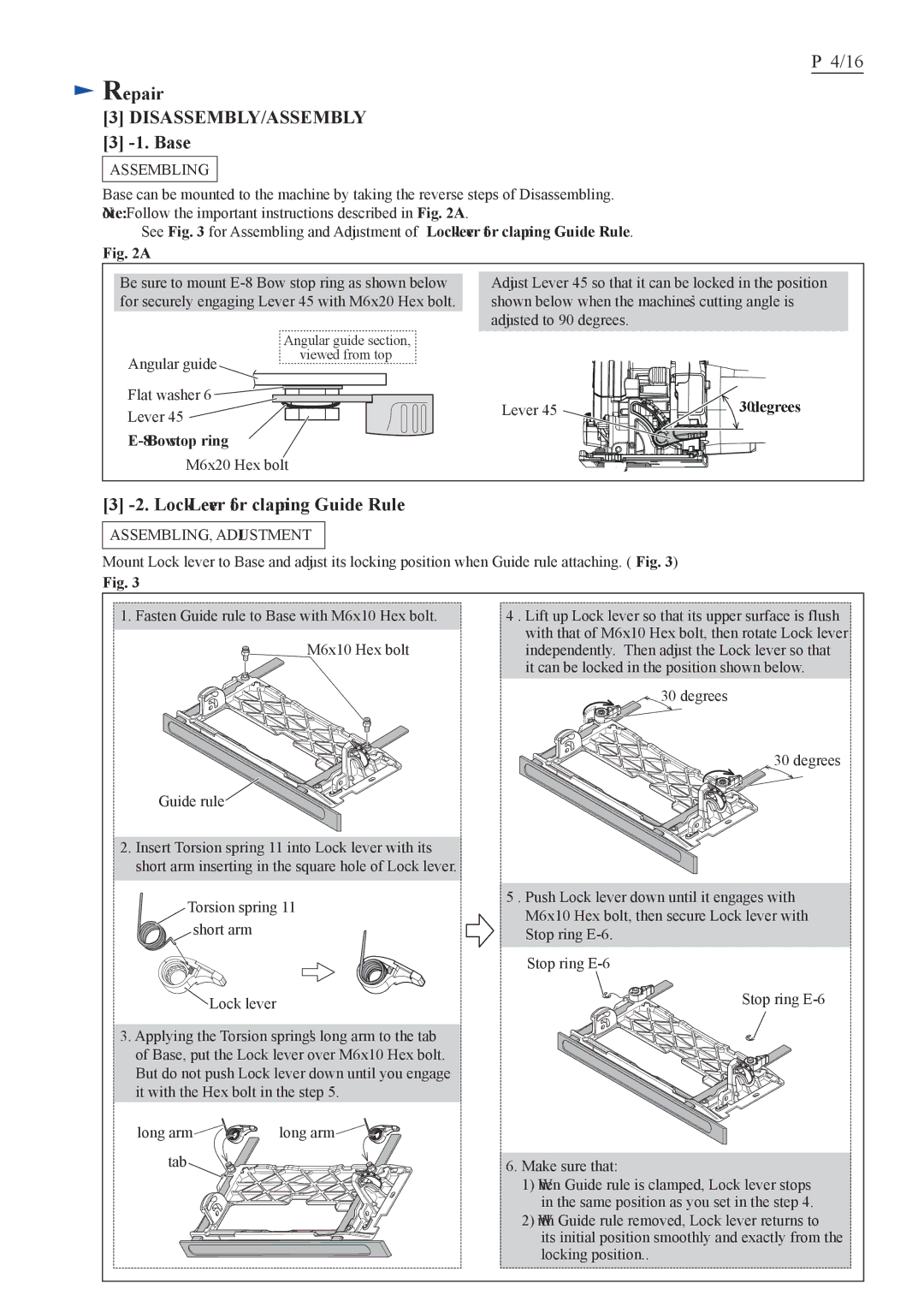

Note: Follow the important instructions described in Fig. 2A.

See Fig. 3 for Assembling and Adjustment of Lock lever for clamping Guide Rule.

Fig. 2A

Be sure to mount

| Angular guide section, |

Angular guide | viewed from top |

|

Flat washer 6 ![]()

![]()

![]()

![]()

![]()

![]()

![]() Lever 45

Lever 45 ![]()

![]()

E-8 Bow stop ring

M6x20 Hex bolt

Adjust Lever 45 so that it can be locked in the position shown below when the machine’s cutting angle is adjusted to 90 degrees.

Lever 45 | 30 degrees |

[3] -2. Lock Lever for clamping Guide Rule

ASSEMBLING, ADJUSTMENT

Mount Lock lever to Base and adjust its locking position when Guide rule attaching. (Fig. 3)

Fig. 3

1. Fasten Guide rule to Base with M6x10 Hex bolt.

M6x10 Hex bolt

Guide rule![]()

2.Insert Torsion spring 11 into Lock lever with its short arm inserting in the square hole of Lock lever.

Torsion spring 11 short arm

![]() Lock lever

Lock lever

3.Applying the Torsion spring's long arm to the tab of Base, put the Lock lever over M6x10 Hex bolt. But do not push Lock lever down until you engage it with the Hex bolt in the step 5.

long arm | long arm |

tab |

|

4 . Lift up Lock lever so that its upper surface is flush with that of M6x10 Hex bolt, then rotate Lock lever independently. Then adjust the Lock lever so that it can be locked in the position shown below.

30 degrees

30 degrees

5 . Push Lock lever down until it engages with M6x10 Hex bolt, then secure Lock lever with Stop ring

Stop ring

Stop ring

6.Make sure that:

1)When Guide rule is clamped, Lock lever stops in the same position as you set in the step 4.

2)With Guide rule removed, Lock lever returns to its initial position smoothly and exactly from the locking position..