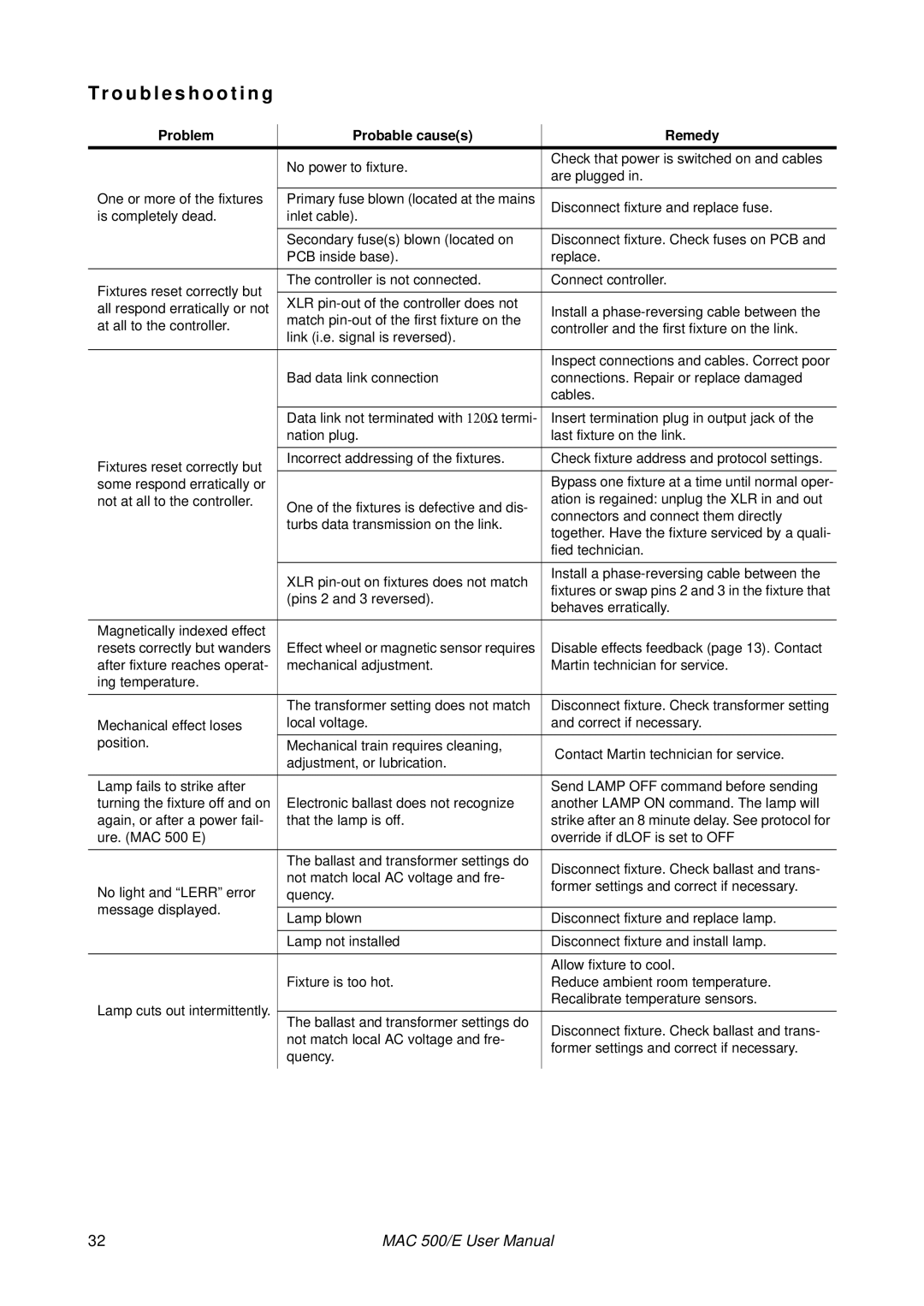

Tr o u b l e s h o o t i n g

Problem | Probable cause(s) | Remedy | |

|

|

| |

| No power to fixture. | Check that power is switched on and cables | |

| are plugged in. | ||

|

| ||

One or more of the fixtures |

|

| |

Primary fuse blown (located at the mains | Disconnect fixture and replace fuse. | ||

is completely dead. | inlet cable). | ||

| |||

|

|

| |

| Secondary fuse(s) blown (located on | Disconnect fixture. Check fuses on PCB and | |

| PCB inside base). | replace. | |

|

|

| |

Fixtures reset correctly but | The controller is not connected. | Connect controller. | |

|

| ||

XLR |

| ||

all respond erratically or not | Install a | ||

match | |||

at all to the controller. | controller and the first fixture on the link. | ||

link (i.e. signal is reversed). | |||

|

| ||

|

|

| |

|

| Inspect connections and cables. Correct poor | |

| Bad data link connection | connections. Repair or replace damaged | |

|

| cables. | |

|

|

| |

| Data link not terminated with 120Ω termi- | Insert termination plug in output jack of the | |

| nation plug. | last fixture on the link. | |

|

|

| |

Fixtures reset correctly but | Incorrect addressing of the fixtures. | Check fixture address and protocol settings. | |

|

| ||

| Bypass one fixture at a time until normal oper- | ||

some respond erratically or |

| ||

not at all to the controller. | One of the fixtures is defective and dis- | ation is regained: unplug the XLR in and out | |

| connectors and connect them directly | ||

| turbs data transmission on the link. | ||

| together. Have the fixture serviced by a quali- | ||

|

| ||

|

| fied technician. | |

|

|

| |

| XLR | Install a | |

| fixtures or swap pins 2 and 3 in the fixture that | ||

| (pins 2 and 3 reversed). | ||

| behaves erratically. | ||

|

| ||

|

|

| |

Magnetically indexed effect |

|

| |

resets correctly but wanders | Effect wheel or magnetic sensor requires | Disable effects feedback (page 13). Contact | |

after fixture reaches operat- | mechanical adjustment. | Martin technician for service. | |

ing temperature. |

|

| |

|

|

| |

| The transformer setting does not match | Disconnect fixture. Check transformer setting | |

Mechanical effect loses | local voltage. | and correct if necessary. | |

position. | Mechanical train requires cleaning, | Contact Martin technician for service. | |

| adjustment, or lubrication. | ||

|

| ||

|

|

| |

Lamp fails to strike after |

| Send LAMP OFF command before sending | |

turning the fixture off and on | Electronic ballast does not recognize | another LAMP ON command. The lamp will | |

again, or after a power fail- | that the lamp is off. | strike after an 8 minute delay. See protocol for | |

ure. (MAC 500 E) |

| override if dLOF is set to OFF | |

|

|

| |

| The ballast and transformer settings do | Disconnect fixture. Check ballast and trans- | |

| not match local AC voltage and fre- | ||

No light and “LERR” error | former settings and correct if necessary. | ||

quency. | |||

| |||

message displayed. |

|

| |

Lamp blown | Disconnect fixture and replace lamp. | ||

| |||

|

|

| |

| Lamp not installed | Disconnect fixture and install lamp. | |

|

|

| |

|

| Allow fixture to cool. | |

| Fixture is too hot. | Reduce ambient room temperature. | |

Lamp cuts out intermittently. |

| Recalibrate temperature sensors. | |

|

| ||

The ballast and transformer settings do | Disconnect fixture. Check ballast and trans- | ||

| |||

| not match local AC voltage and fre- | ||

| former settings and correct if necessary. | ||

| quency. | ||

|

| ||

|

|

|

32 | MAC 500/E User Manual |