C.Preparation for Use with Various Gases

Before proceeding to set up the oven for a specific gas, check that the main gas supply valve and the circuit breaker/fused disconnect are in the OFF ("O") position.

The main and pilot orifices must match the sizes shown in the Gas Orifices and Pressure Specifications table, near the beginning of this Section. If necessary, replace the orifices. Refer to Part D, Replacing the Gas Orifices.

The orifice (manifold) pressure should be adjusted to the value shown in the Gas Orifices and Pressure Specifications table for the specific gas type and location.

1.For Use with Natural Gas

The actual heat input to the oven must match the rated heat input. The input to the burner can be determined using the orifice (manifold) pressure data or by the volume supplied using the gas meter. Both of these procedures are described in Part F, Adjusting the Orifice (Manifold) Pressure and Heat Input.

If the measured input does not correspond with the rated input (shown in the Gas Orifices and Pressure Specifications table), check first that the correct orifices are installed. If the orifices are correct, check and correct the supply and orifice pressures to obtain the correct input based on the gas meter reading.

2.For Use with Liquid Propane (LP) Gas

When using liquid gas, the converter in the multifunction gas valve must be removed, and then replaced INVERTED from its former position. See Figure

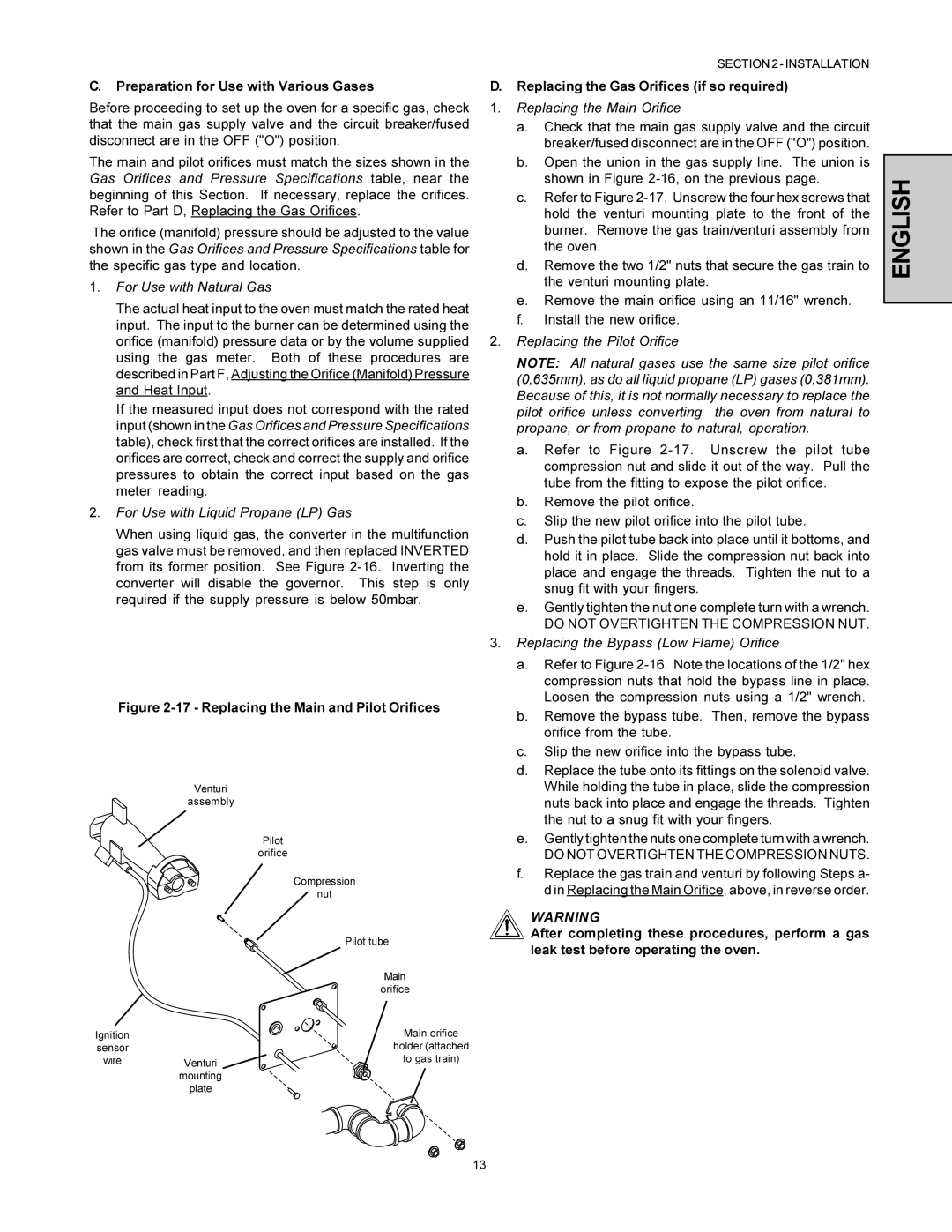

Figure 2-17 - Replacing the Main and Pilot Orifices

Venturi

assembly

Pilot

orifice

|

| Compression |

|

| nut |

|

| Pilot tube |

|

| Main |

|

| orifice |

Ignition |

| Main orifice |

sensor |

| holder (attached |

wire | Venturi | to gas train) |

| mounting |

|

| plate |

|

SECTION 2 - INSTALLATION

D.Replacing the Gas Orifices (if so required)

1.Replacing the Main Orifice

a.Check that the main gas supply valve and the circuit breaker/fused disconnect are in the OFF ("O") position.

b.Open the union in the gas supply line. The union is shown in Figure

c.Refer to Figure

d.Remove the two 1/2" nuts that secure the gas train to the venturi mounting plate.

e.Remove the main orifice using an 11/16" wrench.

f.Install the new orifice.

2.Replacing the Pilot Orifice

NOTE: All natural gases use the same size pilot orifice (0,635mm), as do all liquid propane (LP) gases (0,381mm). Because of this, it is not normally necessary to replace the pilot orifice unless converting the oven from natural to propane, or from propane to natural, operation.

a.Refer to Figure

b.Remove the pilot orifice.

c.Slip the new pilot orifice into the pilot tube.

d.Push the pilot tube back into place until it bottoms, and hold it in place. Slide the compression nut back into place and engage the threads. Tighten the nut to a snug fit with your fingers.

e.Gently tighten the nut one complete turn with a wrench.

DO NOT OVERTIGHTEN THE COMPRESSION NUT.

3.Replacing the Bypass (Low Flame) Orifice

a.Refer to Figure

b.Remove the bypass tube. Then, remove the bypass orifice from the tube.

c.Slip the new orifice into the bypass tube.

d.Replace the tube onto its fittings on the solenoid valve. While holding the tube in place, slide the compression nuts back into place and engage the threads. Tighten the nut to a snug fit with your fingers.

e.Gently tighten the nuts one complete turn with a wrench.

DO NOT OVERTIGHTEN THE COMPRESSION NUTS.

f.Replace the gas train and venturi by following Steps a- d in Replacing the Main Orifice, above, in reverse order.

WARNING

After completing these procedures, perform a gas leak test before operating the oven.

ENGLISH

13