PS540G specifications

The Middleby Marshall PS540G is a cutting-edge conveyor oven designed to meet the diverse cooking needs of commercial kitchens and food service operations. Known for its efficiency and reliability, the PS540G combines advanced technology with innovative design to deliver consistent cooking results while optimizing energy use.One of the standout features of the PS540G is its high-efficiency impingement cooking system. This technology utilizes powerful jets of hot air that quickly and evenly circulate around the food, ensuring thorough cooking while significantly reducing cooking times. This results in faster service and improved throughput, making it an excellent choice for busy restaurants, cafes, and catering operations.

The oven is equipped with a unique dual-fuel option, allowing operators to choose between natural gas or propane. This flexibility helps businesses adapt to their specific requirements and preferences, providing both cost and energy-saving benefits. Additionally, the PS540G is designed with a fully insulated structure, minimizing heat loss and further enhancing energy efficiency.

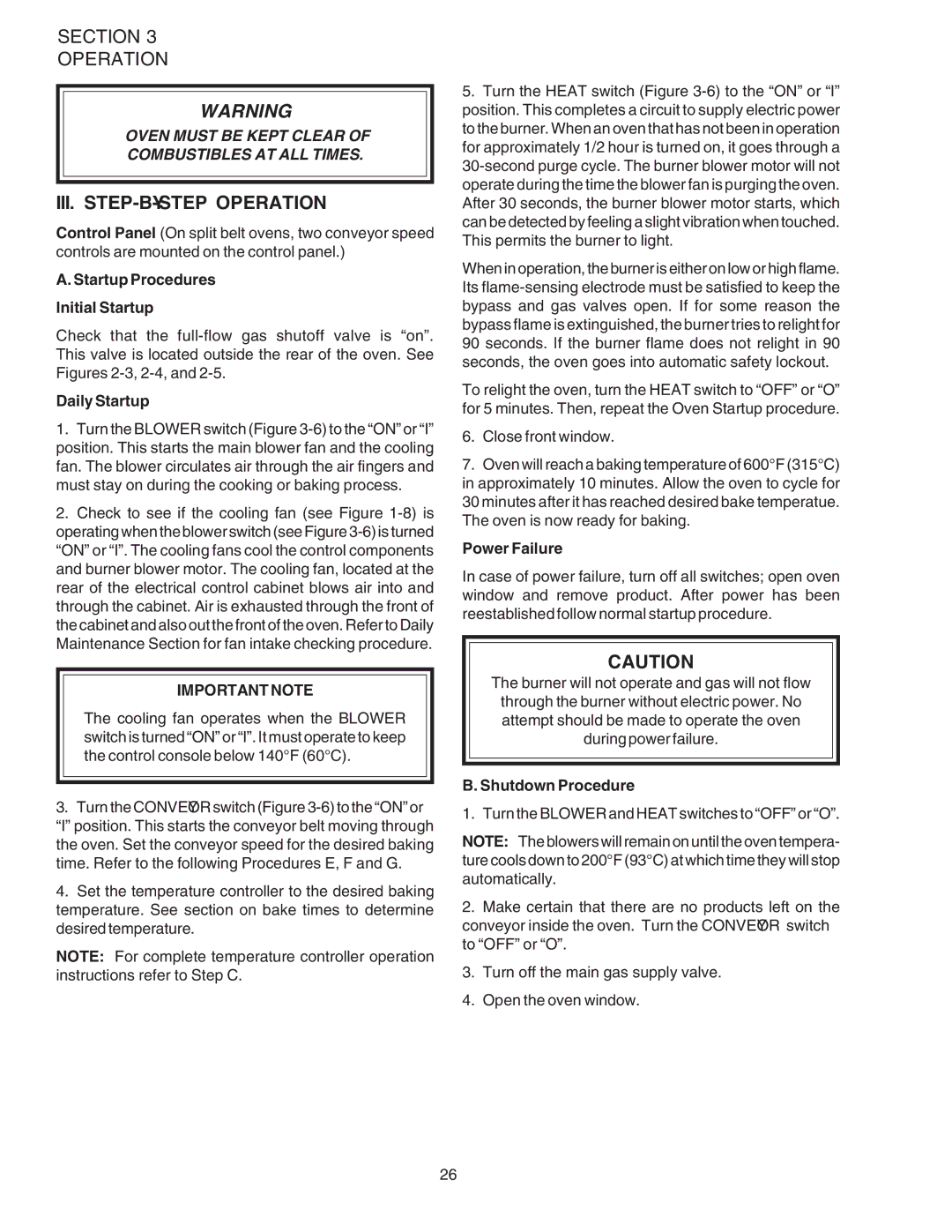

Another key characteristic of the Middleby Marshall PS540G is its user-friendly control interface. The digital controls offer precise temperature settings and adjustable conveyor speeds, allowing chefs to customize the cooking process for various food items. This versatility ensures optimal results, whether baking pizzas, roasting vegetables, or toasting sandwiches.

The spacious cooking chamber of the PS540G is designed with a wide conveyor belt that accommodates large batches of food, making it particularly suitable for high-volume establishments. The oven's compact footprint allows it to fit into tight kitchen spaces without sacrificing cooking capacity.

Safety is also a priority in the design of the PS540G. The oven features automatic shut-off mechanisms and cool-to-the-touch exterior surfaces, allowing for safer operations. Additionally, the durable construction with stainless steel components ensures longevity and ease of maintenance.

In conclusion, the Middleby Marshall PS540G is a state-of-the-art conveyor oven that offers outstanding performance for commercial kitchens. With its advanced impingement cooking technology, flexible dual-fuel options, user-friendly controls, and robust safety features, the PS540G stands out as an essential tool for any food service operation looking to enhance efficiency and food quality.