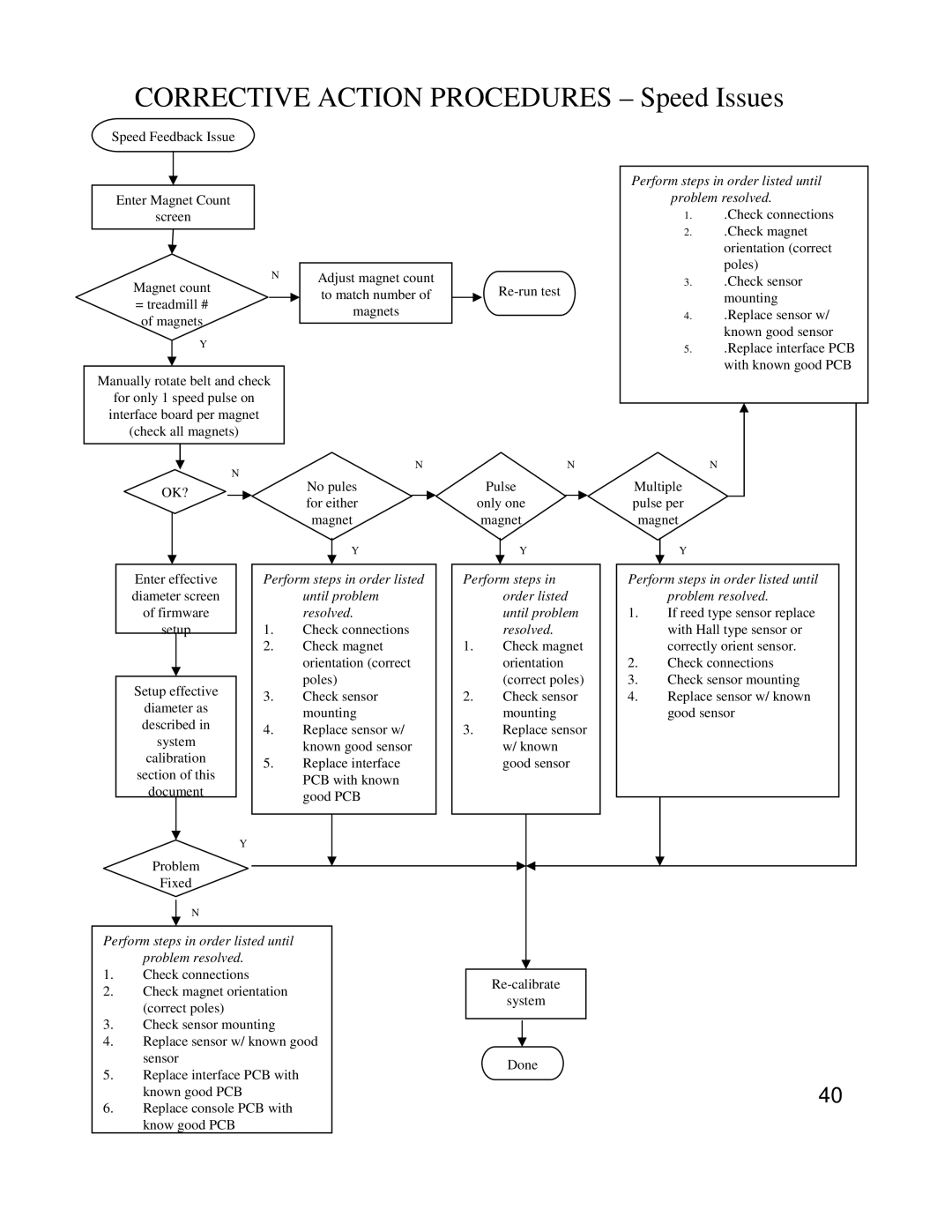

CORRECTIVE ACTION PROCEDURES – Speed Issues

Speed Feedback Issue

Enter Magnet Count

screen

N

Magnet count = treadmill # of magnets

Y

Manually rotate belt and check

for only 1 speed pulse on interface board per magnet (check all magnets)

N

OK?

Adjust magnet count to match number of magnets

N

No pules for either magnet

Y

N

Pulse

only one

magnet

Y

Perform steps in order listed until problem resolved.

1. .Check connections

2. .Check magnet orientation (correct poles)

3. .Check sensor mounting

4. .Replace sensor w/ known good sensor

5. .Replace interface PCB with known good PCB

N

Multiple pulse per magnet

Y

Enter effective diameter screen of firmware setup

Setup effective

diameter as described in system calibration section of this document

Perform steps in order listed until problem resolved.

1.Check connections

2.Check magnet orientation (correct poles)

3.Check sensor mounting

4.Replace sensor w/ known good sensor

5.Replace interface PCB with known good PCB

Perform steps in order listed until problem resolved.

1.Check magnet orientation (correct poles)

2.Check sensor mounting

3.Replace sensor w/ known good sensor

Perform steps in order listed until problem resolved.

1.If reed type sensor replace with Hall type sensor or correctly orient sensor.

2.Check connections

3.Check sensor mounting

4.Replace sensor w/ known good sensor

Y

Problem

Fixed

N

Perform steps in order listed until problem resolved.

1.Check connections

2.Check magnet orientation (correct poles)

3.Check sensor mounting

4.Replace sensor w/ known good sensor

5.Replace interface PCB with known good PCB

6.Replace console PCB with know good PCB

system

Done

40