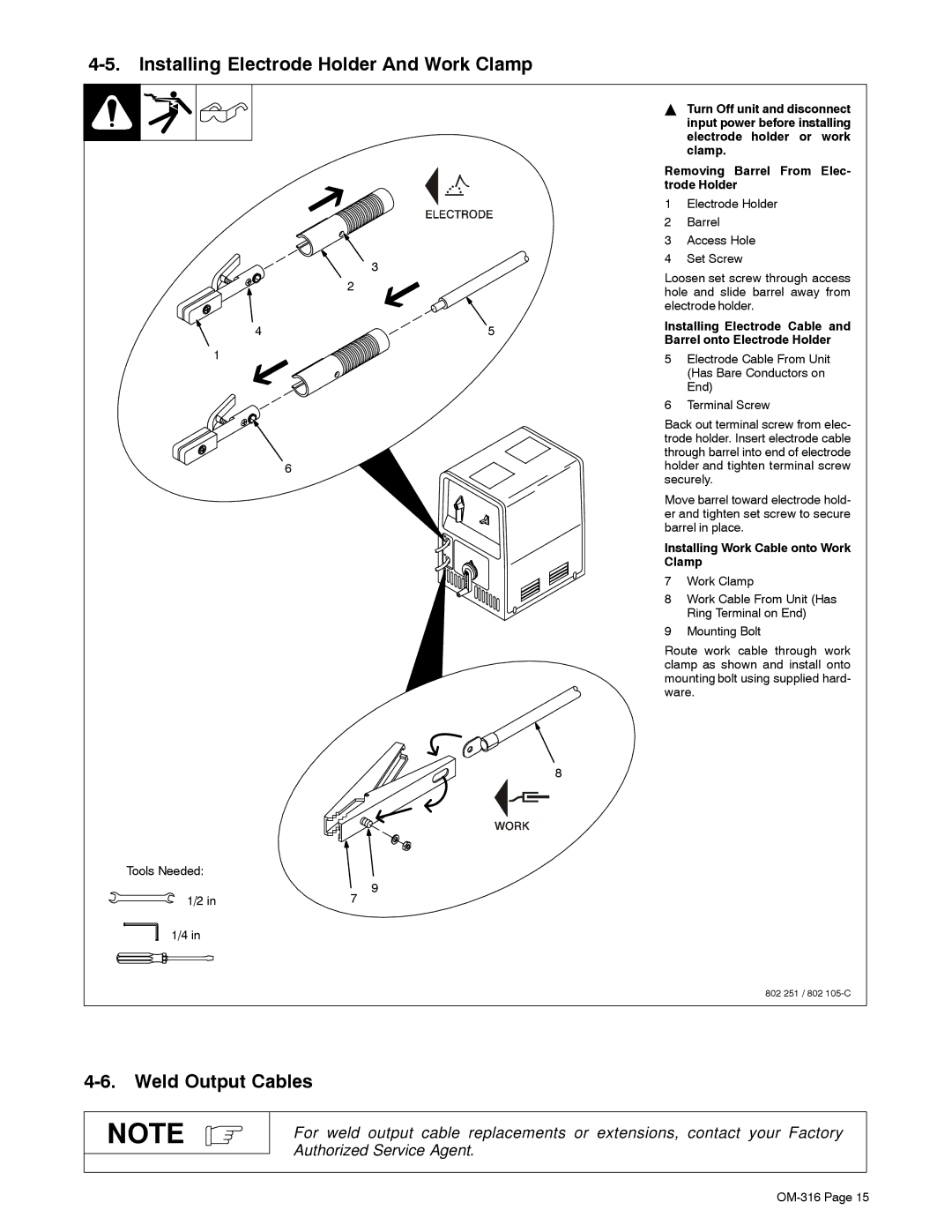

4-5. Installing Electrode Holder And Work Clamp

3

2

4 | 5 |

1

6

8

Tools Needed:

9

1/2 in7 1/4 in

YTurn Off unit and disconnect input power before installing electrode holder or work clamp.

Removing Barrel From Elec- trode Holder

1Electrode Holder

2Barrel

3Access Hole

4Set Screw

Loosen set screw through access hole and slide barrel away from electrode holder.

Installing Electrode Cable and Barrel onto Electrode Holder

5Electrode Cable From Unit (Has Bare Conductors on End)

6Terminal Screw

Back out terminal screw from elec- trode holder. Insert electrode cable through barrel into end of electrode holder and tighten terminal screw securely.

Move barrel toward electrode hold- er and tighten set screw to secure barrel in place.

Installing Work Cable onto Work Clamp

7Work Clamp

8Work Cable From Unit (Has Ring Terminal on End)

9Mounting Bolt

Route work cable through work clamp as shown and install onto mounting bolt using supplied hard- ware.

802 251 / 802

4-6. Weld Output Cables

NOTE

For weld output cable replacements or extensions, contact your Factory Authorized Service Agent.