SECTION 8 − WELDING METHODS & TROUBLESHOOTING

mod5.1* 9/92

A. Welding Methods

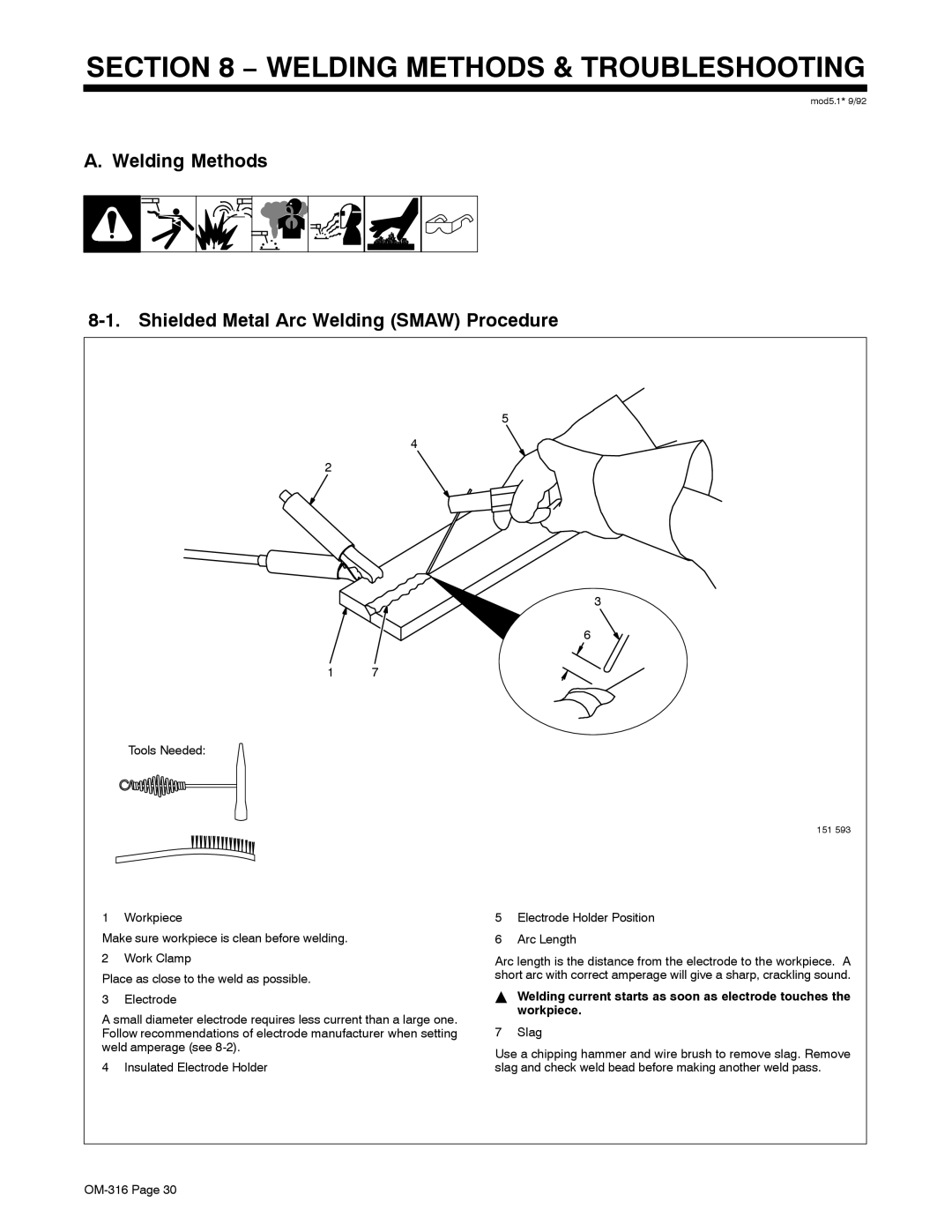

8-1. Shielded Metal Arc Welding (SMAW) Procedure

5

4

2

3

6

1 7

Tools Needed:

151 593

1 Workpiece

Make sure workpiece is clean before welding.

2 Work Clamp

Place as close to the weld as possible.

3 Electrode

A small diameter electrode requires less current than a large one. Follow recommendations of electrode manufacturer when setting weld amperage (see

4 Insulated Electrode Holder

5Electrode Holder Position

6Arc Length

Arc length is the distance from the electrode to the workpiece. A short arc with correct amperage will give a sharp, crackling sound.

YWelding current starts as soon as electrode touches the workpiece.

7 Slag

Use a chipping hammer and wire brush to remove slag. Remove slag and check weld bead before making another weld pass.