| Table |

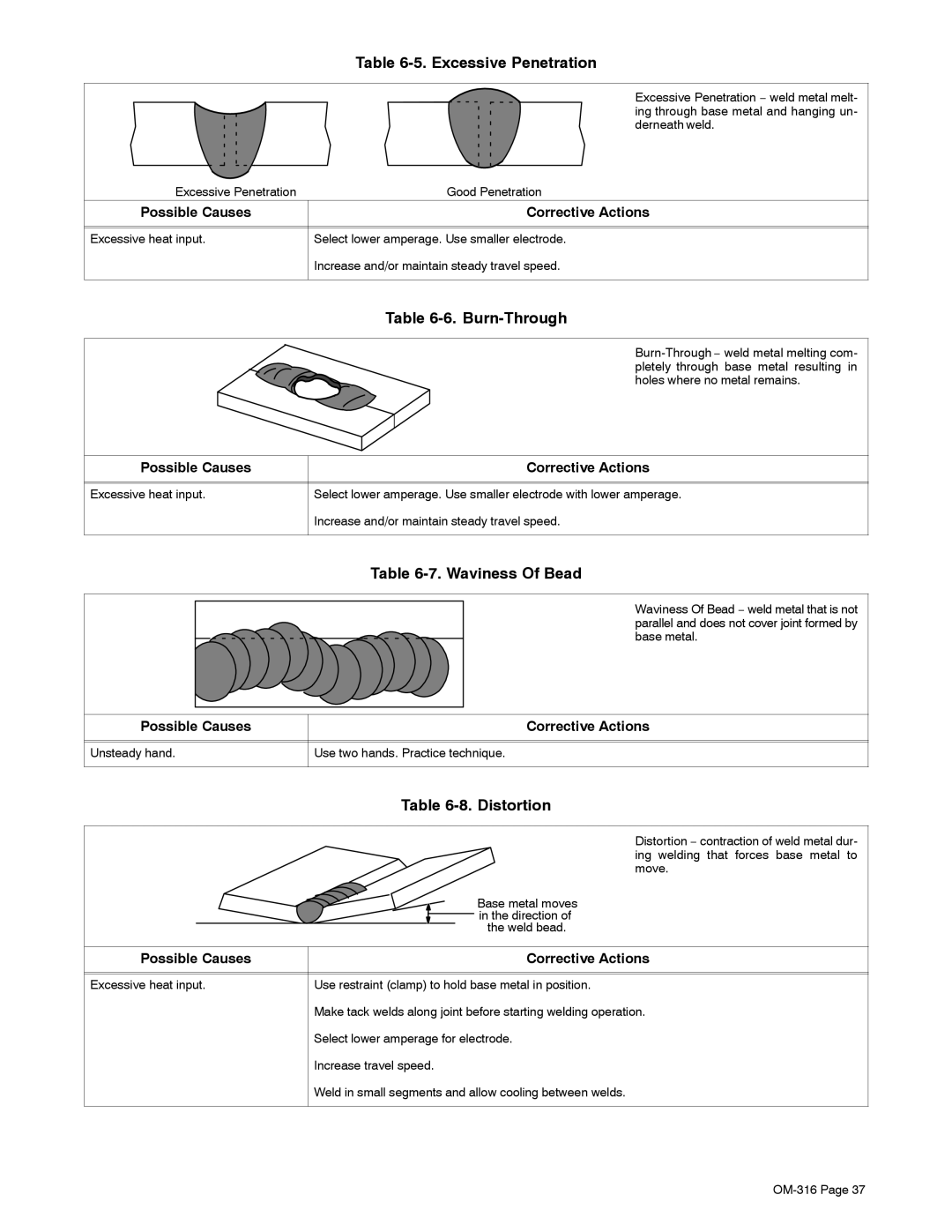

| Excessive Penetration − weld metal melt- |

| ing through base metal and hanging un- |

| derneath weld. |

Excessive Penetration | Good Penetration |

Possible Causes | Corrective Actions |

Excessive heat input. | Select lower amperage. Use smaller electrode. |

| Increase and/or maintain steady travel speed. |

| Table |

| |

| pletely through base metal resulting in |

| holes where no metal remains. |

Possible Causes | Corrective Actions |

|

|

|

|

Excessive heat input. | Select lower amperage. Use smaller electrode with lower amperage. |

| Increase and/or maintain steady travel speed. |

|

|

Table 6-7. Waviness Of Bead

Waviness Of Bead − weld metal that is not parallel and does not cover joint formed by base metal.

Possible Causes | Corrective Actions |

|

|

|

|

Unsteady hand. | Use two hands. Practice technique. |

|

|

Table 6-8. Distortion

Distortion − contraction of weld metal dur- ing welding that forces base metal to move.

|

|

| Base metal moves |

|

|

| in the direction of |

|

|

| |

|

|

| the weld bead. |

|

|

|

|

Possible Causes |

|

| Corrective Actions |

|

| ||

|

| ||

Excessive heat input. | Use restraint (clamp) to hold base metal in position. | ||

| Make tack welds along joint before starting welding operation. | ||

| Select lower amperage for electrode. | ||

| Increase travel speed. | ||

| Weld in small segments and allow cooling between welds. | ||

|

|

|

|