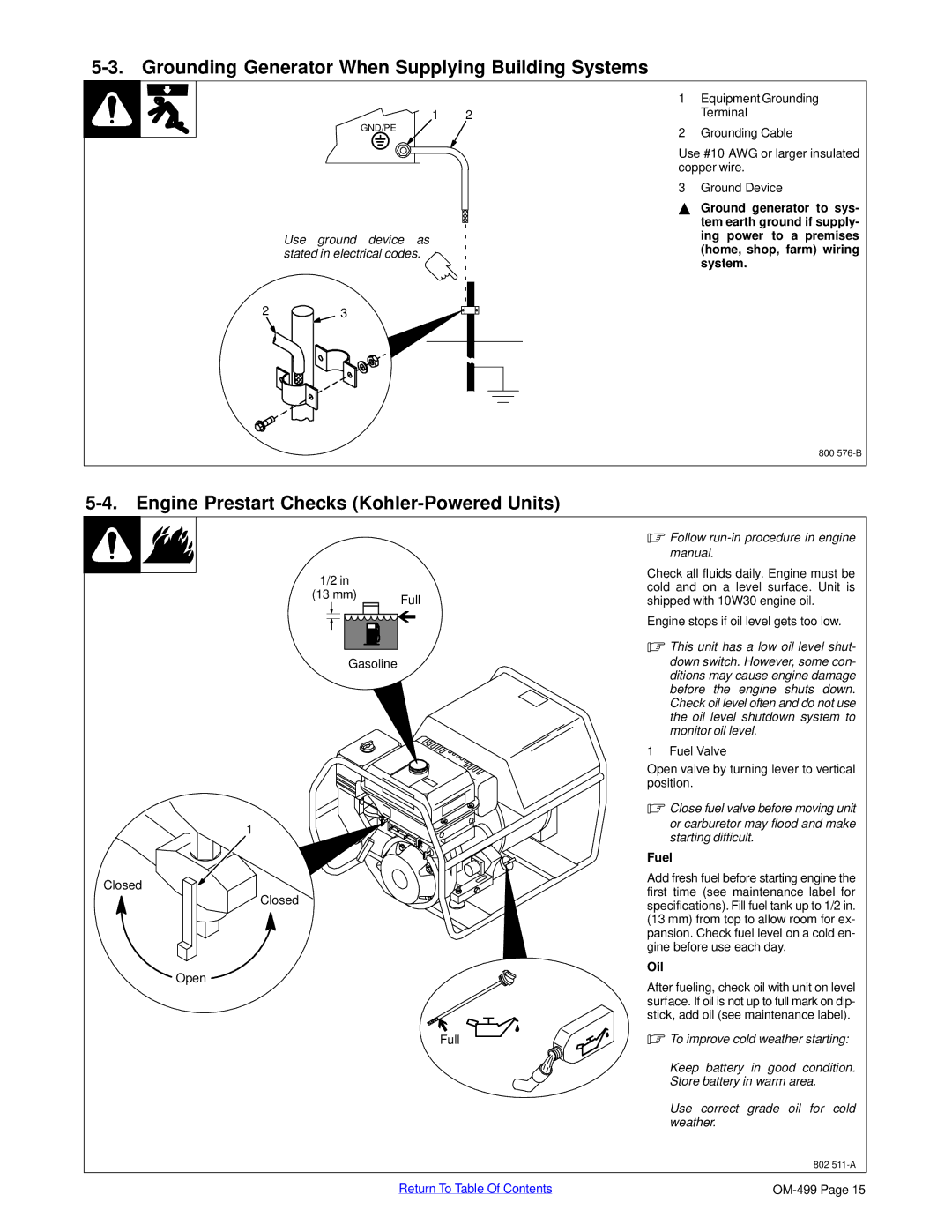

5-3. Grounding Generator When Supplying Building Systems

1 2

GND/PE

Use ground device as stated in electrical codes.

23

1Equipment Grounding Terminal

2Grounding Cable

Use #10 AWG or larger insulated copper wire.

3 Ground Device

YGround generator to sys- tem earth ground if supply- ing power to a premises (home, shop, farm) wiring system.

800

5-4. Engine Prestart Checks (Kohler-Powered Units)

1/2 in |

|

(13 mm) | Full |

| |

Gasoline |

|

1

Closed

Closed

Open

Full

.Follow run-in procedure in engine manual.

Check all fluids daily. Engine must be cold and on a level surface. Unit is shipped with 10W30 engine oil.

Engine stops if oil level gets too low.

.This unit has a low oil level shut- down switch. However, some con- ditions may cause engine damage before the engine shuts down. Check oil level often and do not use the oil level shutdown system to monitor oil level.

1 Fuel Valve

Open valve by turning lever to vertical position.

.Close fuel valve before moving unit or carburetor may flood and make starting difficult.

Fuel

Add fresh fuel before starting engine the first time (see maintenance label for specifications). Fill fuel tank up to 1/2 in. (13 mm) from top to allow room for ex- pansion. Check fuel level on a cold en- gine before use each day.

Oil

After fueling, check oil with unit on level surface. If oil is not up to full mark on dip- stick, add oil (see maintenance label).

.To improve cold weather starting:

Keep battery in good condition. Store battery in warm area.

Use correct grade oil for cold weather.

802

Return To Table Of Contents |