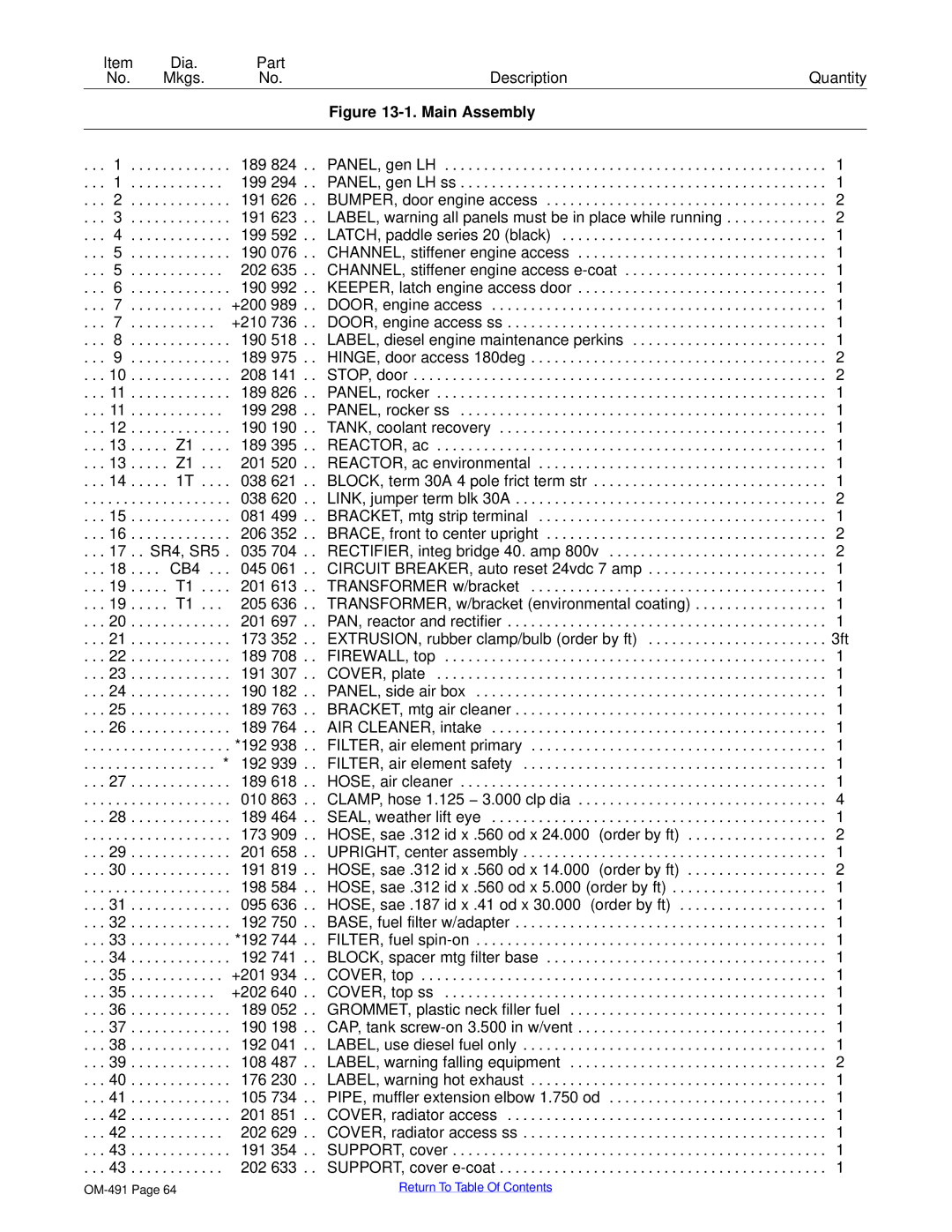

Item | Dia. | | Part | | | |

| No. | Mkgs. | | No. | Description | | Quantity |

| | | | | Figure 13-1. Main Assembly | | |

| | | | | | | |

. . . | 1 . . | . . . . . . . . | . . . | 189 824 . . | PANEL, gen LH | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . | 1 . . | . . . . . . . . | . . ♦199 294 . . | PANEL, gen LH ss | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . | 2 . . | . . . . . . . . | . . . | 191 626 . . | BUMPER, door engine access | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 2 |

. . . | 3 . . | . . . . . . . . | . . . | 191 623 . . | LABEL, warning all panels must be in place while running | . . . 2 |

. . . | 4 . . | . . . . . . . . | . . . | 199 592 . . | LATCH, paddle series 20 (black) . . . . | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . | 5 . . | . . . . . . . . | . . . | 190 076 . . | CHANNEL, stiffener engine access . . | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . | 5 . . | . . . . . . . . | . . ♦202 635 . . | CHANNEL, stiffener engine access e-coat | . . . 1 |

. . . | 6 . . | . . . . . . . . | . . . | 190 992 . . | KEEPER, latch engine access door . . | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . | 7 . . | . . . . . . . . | . . | +200 989 . . | DOOR, engine access | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . | 7 . . | . . . . . . . . | . ♦+210 736 . . | DOOR, engine access ss | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . | 8 . . | . . . . . . . . | . . . | 190 518 . . | LABEL, diesel engine maintenance perkins | . . . 1 |

. . . | 9 . . | . . . . . . . . | . . . | 189 975 . . | HINGE, door access 180deg | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 2 |

. . . 10 . . | . . . . . . . . | . . . | 208 141 . . | STOP, door | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 2 |

. . . 11 . . | . . . . . . . . | . . . | 189 826 . . | PANEL, rocker | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 11 . . | . . . . . . . . | . . ♦199 298 . . | PANEL, rocker ss | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 12 . . | . . . . . . . . | . . . | 190 190 . . | TANK, coolant recovery | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 13 . . | . . . Z1 . | . . . | 189 395 . . | REACTOR, ac | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 13 . . | . . . Z1 . | . . ♦201 520 . . | REACTOR, ac environmental | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 14 . . | . . . 1T . | . . . | 038 621 . . | BLOCK, term 30A 4 pole frict term str | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . | . . . . . | . . . . . . . . | . . . | 038 620 . . | LINK, jumper term blk 30A | . . . 2 |

. . . 15 . . | . . . . . . . . | . . . | 081 499 . . | BRACKET, mtg strip terminal | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 16 . . | . . . . . . . . | . . . | 206 352 . . | BRACE, front to center upright | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 2 |

. . . 17 . . | SR4, SR5 . | 035 704 . . | RECTIFIER, integ bridge 40. amp 800v | . . . 2 |

. . . 18 . . | . . CB4 | . . . | 045 061 . . | CIRCUIT BREAKER, auto reset 24vdc 7 amp | . . . 1 |

. . . 19 . . | . . . T1 . | . . . | 201 613 . . | TRANSFORMER w/bracket | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 19 . . | . . . T1 . | . . ♦205 636 . . | TRANSFORMER, w/bracket (environmental coating) | . . . 1 |

. . . 20 . . | . . . . . . . . | . . . | 201 697 . . | PAN, reactor and rectifier | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 21 . . | . . . . . . . . | . . . | 173 352 . . | EXTRUSION, rubber clamp/bulb (order by ft) | . . . 3ft |

. . . 22 . . | . . . . . . . . | . . . | 189 708 . . | FIREWALL, top | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 23 . . | . . . . . . . . | . . . | 191 307 . . | COVER, plate | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 24 . . | . . . . . . . . | . . . | 190 182 . . | PANEL, side air box | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 25 . . | . . . . . . . . | . . . | 189 763 . . | BRACKET, mtg air cleaner | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 26 . . | . . . . . . . . | . . . | 189 764 . . | AIR CLEANER, intake | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . | . . . . . | . . . . . . . . | . . . | *192 938 . . | FILTER, air element primary | . . . 1 |

. . . | . . . . . | . . . . . . . . | . *♦192 939 . . | FILTER, air element safety | . . . 1 |

. . . 27 . . | . . . . . . . . | . . . | 189 618 . . | HOSE, air cleaner | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . | . . . . . | . . . . . . . . | . . . | 010 863 . . | CLAMP, hose 1.125 − 3.000 clp dia | . . . 4 |

. . . 28 . . | . . . . . . . . | . . . | 189 464 . . | SEAL, weather lift eye | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . | . . . . . | . . . . . . . . | . . . | 173 909 . . | HOSE, sae .312 id x .560 od x 24.000 | (order by ft) | . . . 2 |

. . . 29 . . | . . . . . . . . | . . . | 201 658 . . | UPRIGHT, center assembly | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 30 . . | . . . . . . . . | . . . | 191 819 . . | HOSE, sae .312 id x .560 od x 14.000 | (order by ft) | . . . 2 |

. . . | . . . . . | . . . . . . . . | . . . | 198 584 . . | HOSE, sae .312 id x .560 od x 5.000 (order by ft) | . . . 1 |

. . . 31 . . | . . . . . . . . | . . . | 095 636 . . | HOSE, sae .187 id x .41 od x 30.000 | (order by ft) | . . . 1 |

. . . 32 . . | . . . . . . . . | . . . | 192 750 . . | BASE, fuel filter w/adapter | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 33 . . | . . . . . . . . | . . . | *192 744 . . | FILTER, fuel spin-on | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 34 . . | . . . . . . . . | . . . | 192 741 . . | BLOCK, spacer mtg filter base | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 35 . . | . . . . . . . . | . . | +201 934 . . | COVER, top | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 35 . . | . . . . . . . . | . ♦+202 640 . . | COVER, top ss | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 36 . . | . . . . . . . . | . . . | 189 052 . . | GROMMET, plastic neck filler fuel . . . | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 37 . . | . . . . . . . . | . . . | 190 198 . . | CAP, tank screw-on 3.500 in w/vent . . | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 38 . . | . . . . . . . . | . . . | 192 041 . . | LABEL, use diesel fuel only | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 39 . . | . . . . . . . . | . . . | 108 487 . . | LABEL, warning falling equipment . . . | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 2 |

. . . 40 . . | . . . . . . . . | . . . | 176 230 . . | LABEL, warning hot exhaust | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 41 . . | . . . . . . . . | . . . | 105 734 . . | PIPE, muffler extension elbow 1.750 od | . . . 1 |

. . . 42 . . | . . . . . . . . | . . . | 201 851 . . | COVER, radiator access | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 42 . . | . . . . . . . . | . . ♦202 629 . . | COVER, radiator access ss | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 43 . . | . . . . . . . . | . . . | 191 354 . . | SUPPORT, cover | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |

. . . 43 . . | . . . . . . . . | . . ♦202 633 . . | SUPPORT, cover e-coat | . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . 1 |