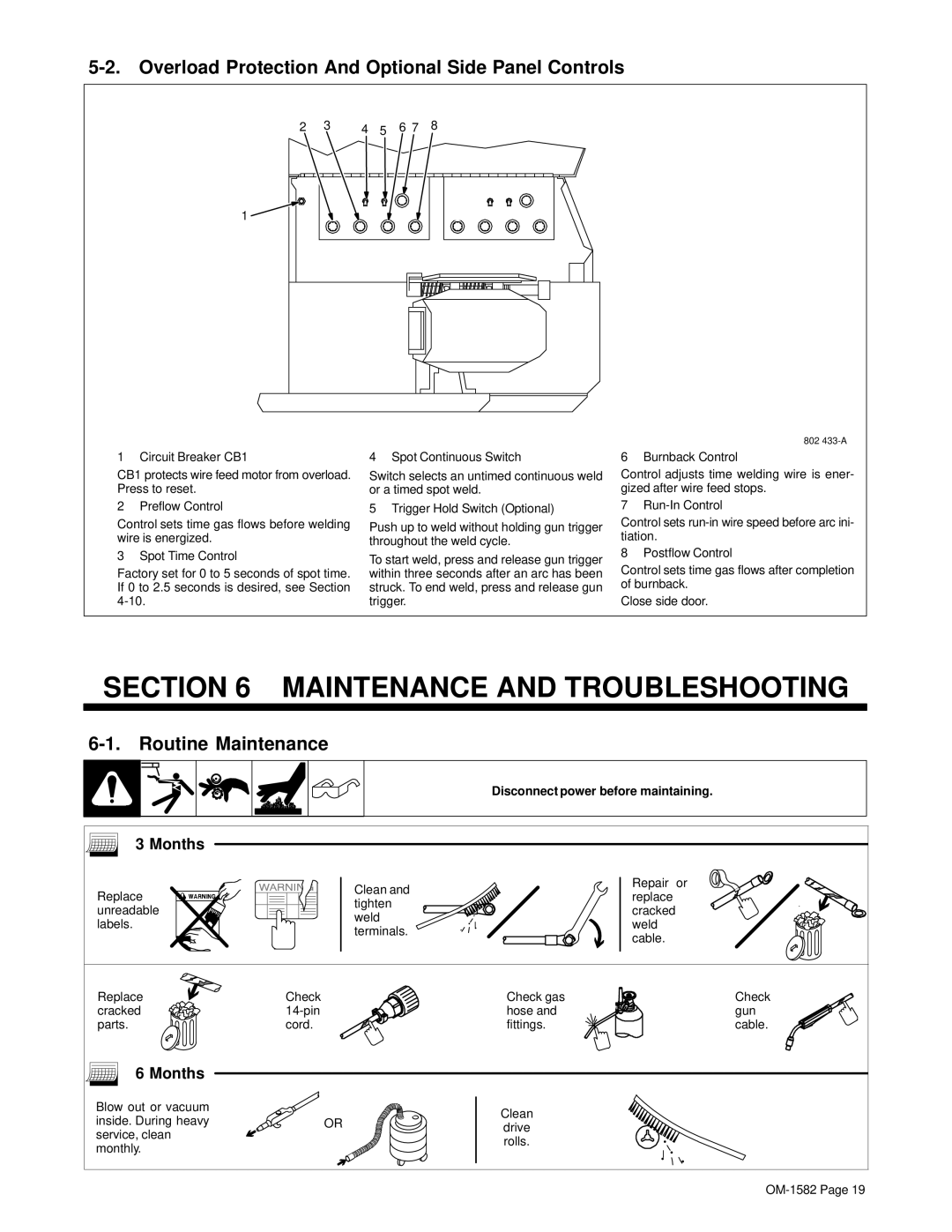

5-2. Overload Protection And Optional Side Panel Controls

2 | 3 | 4 | 5 | 6 7 | 8 |

1 ![]()

1 Circuit Breaker CB1

CB1 protects wire feed motor from overload. Press to reset.

2 Preflow Control

Control sets time gas flows before welding wire is energized.

3 Spot Time Control

Factory set for 0 to 5 seconds of spot time. If 0 to 2.5 seconds is desired, see Section

4 Spot Continuous Switch

Switch selects an untimed continuous weld or a timed spot weld.

5 Trigger Hold Switch (Optional)

Push up to weld without holding gun trigger throughout the weld cycle.

To start weld, press and release gun trigger within three seconds after an arc has been struck. To end weld, press and release gun trigger.

802

6 Burnback Control

Control adjusts time welding wire is ener- gized after wire feed stops.

7

Control sets

8 Postflow Control

Control sets time gas flows after completion of burnback.

Close side door.

SECTION 6 – MAINTENANCE AND TROUBLESHOOTING

6-1. Routine Maintenance

Y Disconnect power before maintaining.

3 Months |

|

|

|

|

|

Replace |

|

| Clean and | Repair | or |

|

| replace |

| ||

|

| tighten |

| ||

unreadable |

|

| cracked |

| |

|

| weld |

| ||

labels. |

|

| weld |

| |

|

| terminals. |

| ||

|

|

| cable. |

| |

|

|

|

|

| |

Replace | Check |

|

| Check gas | Check |

cracked |

|

| hose and | gun | |

parts. | cord. |

|

| fittings. | cable. |

6 Months |

|

|

|

|

|

Blow out or vacuum |

|

|

| Clean |

|

inside. During heavy |

| OR |

|

| |

|

| drive |

| ||

service, clean |

|

|

|

| |

|

|

| rolls. |

| |

monthly. |

|

|

|

| |

|

|

|

|

| |

|

|

|

|

|